16

MotorComponentTestingandInspectionELECTRICVEHICLE-MOTOR

754

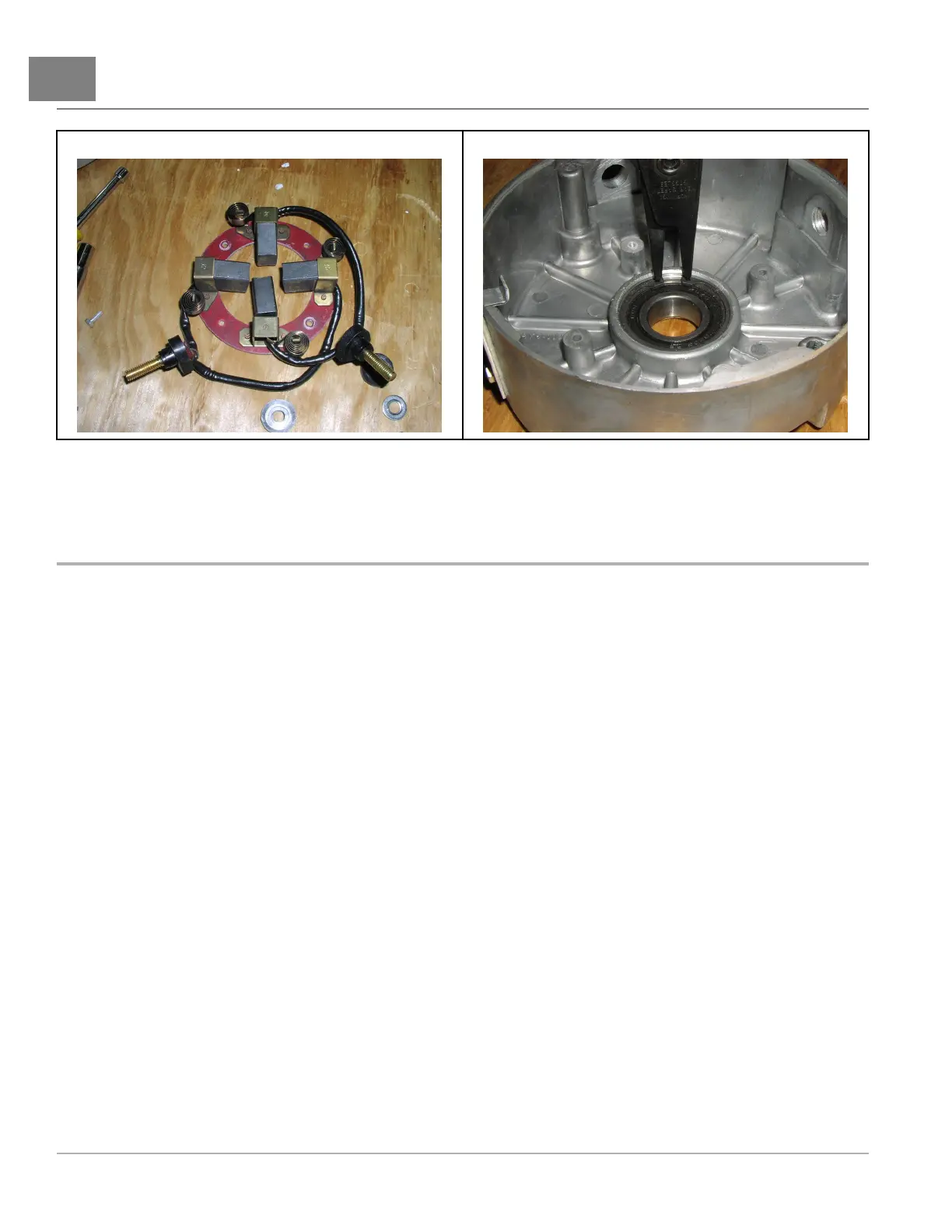

Figure16-10BrushRigging

755

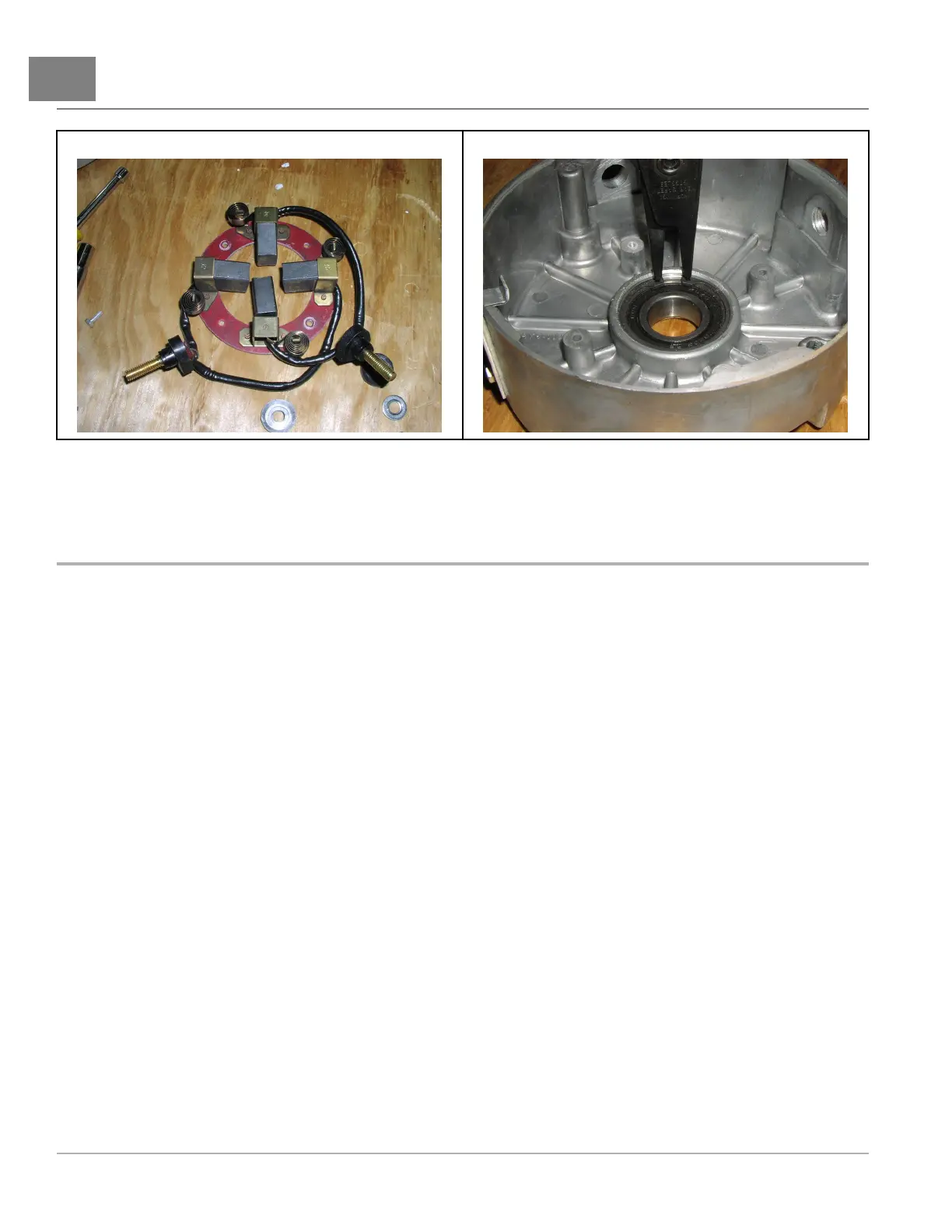

Figure16-11BearingRetainingRing

MOTORCOMPONENTTESTINGANDINSPECTION

SeeGeneralWarningsonpage1-2.

ARMATUREINSPECTIONANDTESTING

1.Removethemotorfromthevehicle.SeeMotorRemovalonpage16-4.

2.Removetheendcapandarmaturebyperformingsteps1through7ofMotorDisassemblyonpage16-5.

VisualInspection

•Burned,charredorcrackedinsulation

•Improperlycuredvarnish

•Thrownsolder

•Flaredarmaturewindings

•Damagedarmaturecorelaminations

•Worn,burnedorglazedcommutators

•Dirtyoroilycommutators

•Raisedcommutatorbars

•Wornarmaturebearingorshaft

Adirtyoroilycommutatorshouldbecleanedandwipeddry.Abnormalitiesidentiedduringtheinspectioncanhelp

determineoriginalcauseoffailure.Slightroughnessofthecommutatorcanbepolishedsmoothwith400gritor

nersandpaper.SeefollowingCAUTIONandNOTE.

Page16-82020Precedent,Villager2and4MaintenanceandServiceManual

Loading...

Loading...