ELECTRICVEHICLE-MOTORMotorInstallation

16

8.Makesurethearmatureturnsfreely.Ifitdoesnotturnfreely,disassemblethemotortondtheproblem.

MOTORINSTALLATION

SeeGeneralWarningsonpage1-2.

1.Cleanthetransaxleinputshaft.

1.1.SpraytheinputshaftthoroughlywithCRC

®

Brakleen™orequivalentbrakecleanerdegreaser.

1.2.Wipeinputshaftwithacleancloth.

1.3.Inspectthegroovesoftheinputshaftandremoveanyremainingdebris.

1.4.Repeatsteps1.1through1.3untilinputshaftisclean.

2.Lubricatethetransaxleinputshaft.

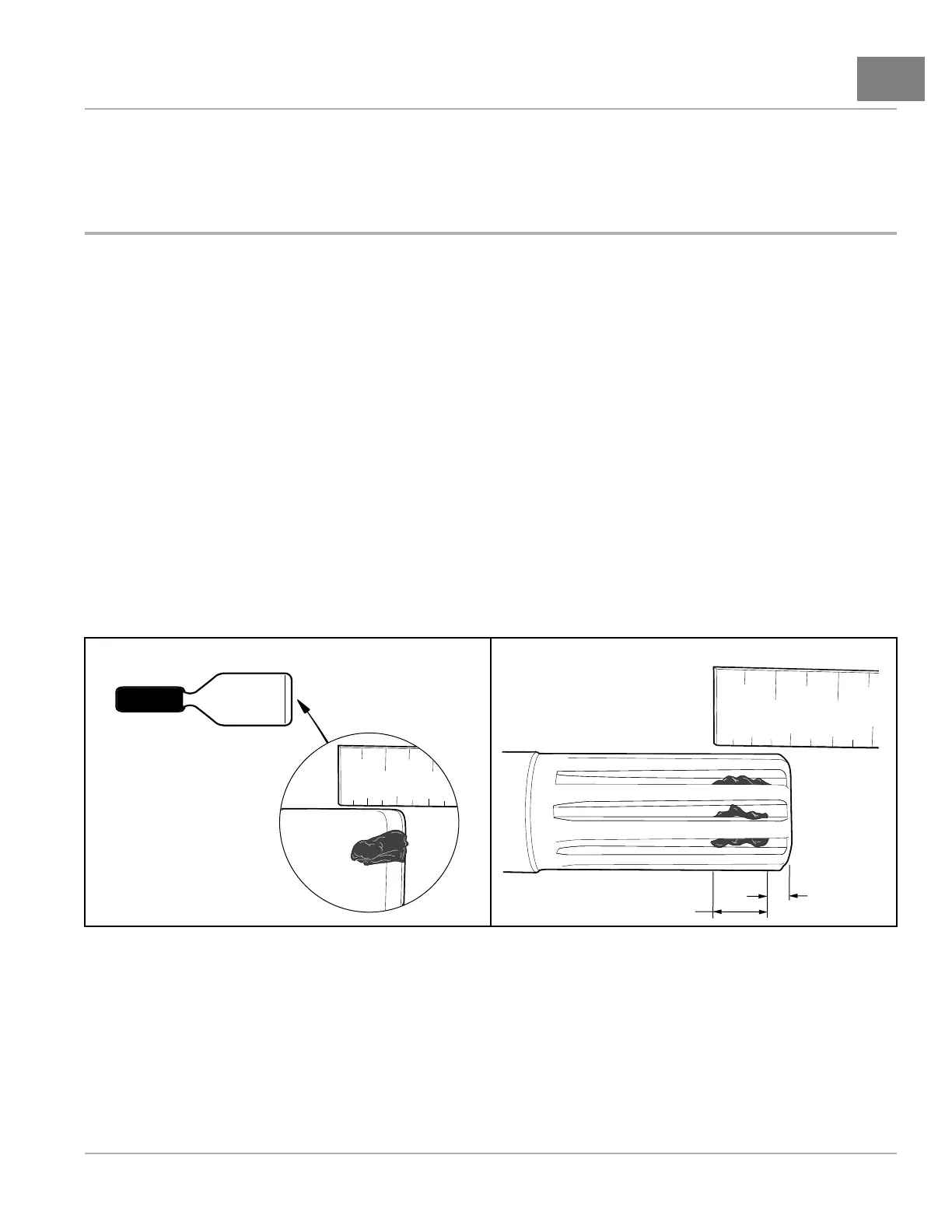

2.1.Squeezeapproximately1/2inch(1.3cm)ofmoly-teonlubricantfromtubeontoaputtyknifeasshown

(Figure16-20,Page16-15).

2.2.Rotatewheelstorotateinputshaft.

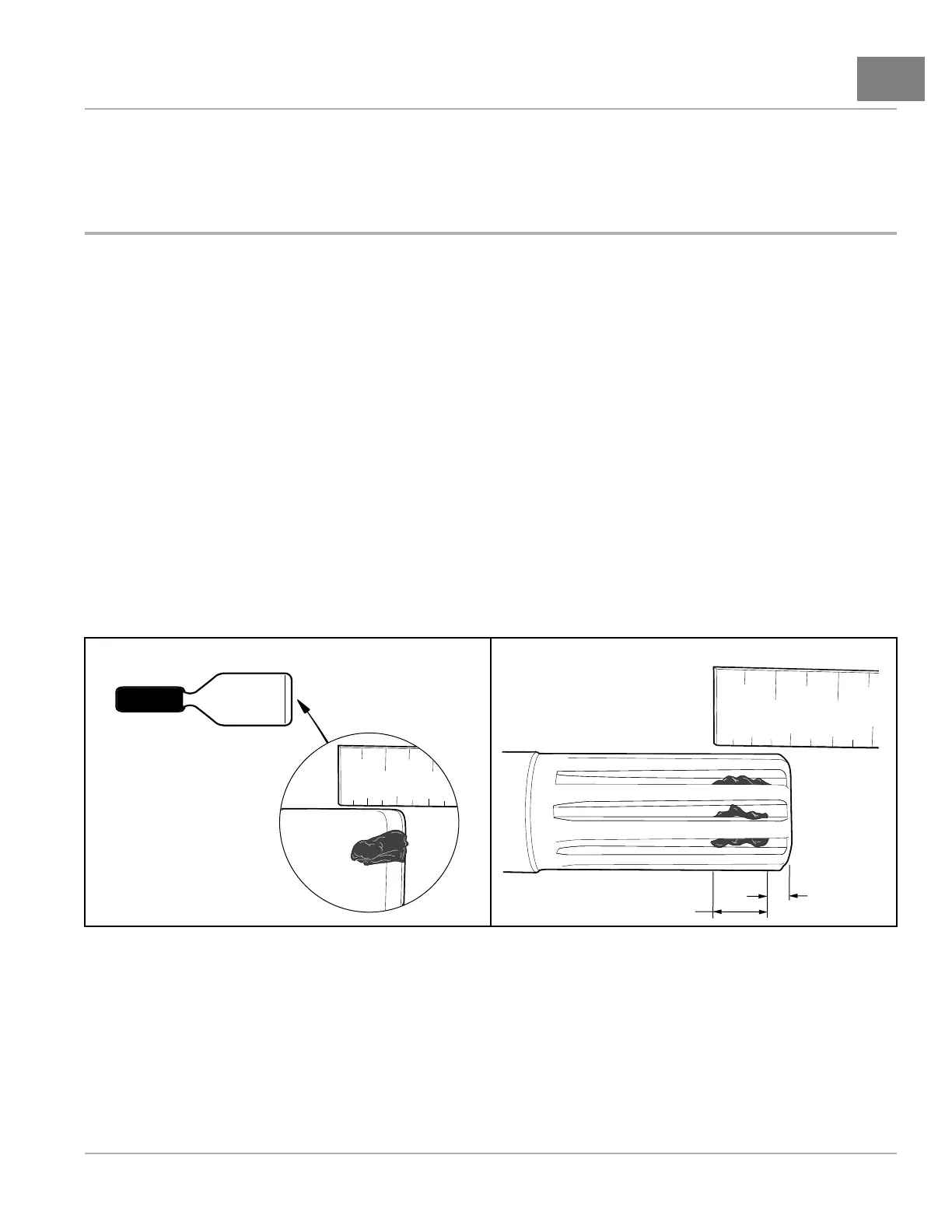

2.3.Applymotorcouplinggreaseevenlytotherotatinginputshaftstartingatapproximately1/8inch(3.1

mm)fromtheendoftheshaftandworkingbacktowardthetransaxle(awayfromtheendoftheshaft)

(Figure16-21,Page16-15).

2.4.Thegreaseshouldbeevenlydistributedinthegroovestoawidthofapproximately3/8inch(9.5mm).

2.5.Useaatscrewdrivertocleanthegreaseoutofoneofthegroovesandallowairtoescapewhenthe

motorispushedontotheinputshaft.

1

2

1

1/2

mm

inch

1/8 INCH

(3.1 MM)

3/8 INCH (9.5 MM)

741

Figure16-20GreaseonPuttyKnife

742

Figure16-21ApplicationofgreasetoInputShaftGrooves

2.6.Checkthechamfer(1)andend(2)oftheinputshafttoensuretheseareasarecompletelycleanofgrease

asshown(Figure16-22,Page16-16).

3.Installthemoldedbumper.

3.1.Withtheatsidetowardthebottomofthecouplingandthecuppedsidetowardthetransaxleinputshaft,

installthemoldedbumper(30)intothemotorcoupling(Figure16-15,Page16-12).SeefollowingNOTE.

NOTE:Themotorcouplingandthenewmoldedbumpermustbefreeofgreaseanddebris.

3.2.Ensurethattheinstalledbumperisseatedatthebottomofthecoupling.

2020Precedent,Villager2and4MaintenanceandServiceManualPage16-15

Loading...

Loading...