General overhaul instructions

• After taking the fork apart, always use new, genuine Marzocchi seals on assembly.

• When tightening two screws or nuts close to each other, always follow a 1-2-1 pattern and use a torque wrench; observe the speci-

ed tightening torque values (see Tightening torque gures table).

• Never use ammable or corrosive solvent to clean parts, or you might damage the seals. If needed, use specic detergents, prefer-

ably biodegradable, non corrosive, non ammable or with high ash point, compatible with seal materials.

• Always lubricate the mating surfaces of fork parts before assembly.

If the fork is to be left unused for long periods of time, lubricate all mating parts with fork oil.

• Never release lubricants, solvents or detergents that are not fully biodegradable into the environment; collect them suitable con-

tainers and dispose of them according to applicable rules.

• Always grease sealing ring lips before assembly.

• Use only metric tools. Never use (US) imperial tools. (US) imperial tools of sizes close to those of metric tools may damage bolts

and screws and make them impossible to remove.

• Use a screwdriver of the appropriate type and size to unscrew slot head or Phillips screws.

• When using a screwdriver to install or remove metal retaining rings, O-rings, pilot bushings or seals, avoid damaging the compo-

nents with the tip of the screwdriver.

• Use only genuine Marzocchi parts.

• Before servicing the front fork, make sure to have a Marzocchi service kit for your fork (if applicable) available, including the neces-

sary parts for a complete fork service or overhaul.

• Perform service in a clean, orderly, well lit environment. Avoid servicing the

fork outdoors.

• Make sure the work area is free from metal ling or dust.

• Thoroughly wash the motorcycle and especially the fork before servicing.

• Never use jet cleaners to wash the motorcycle.

• Even using a gardening hose might cause the pressurised water jet to get

past the seals and affect the proper operation of your Marzocchi fork. Clean

motorcycle and Marzocchi forks thoroughly with water and neutral soap.

• It is good practice to service one fork leg at a time.

• Do not make changes to fork components.

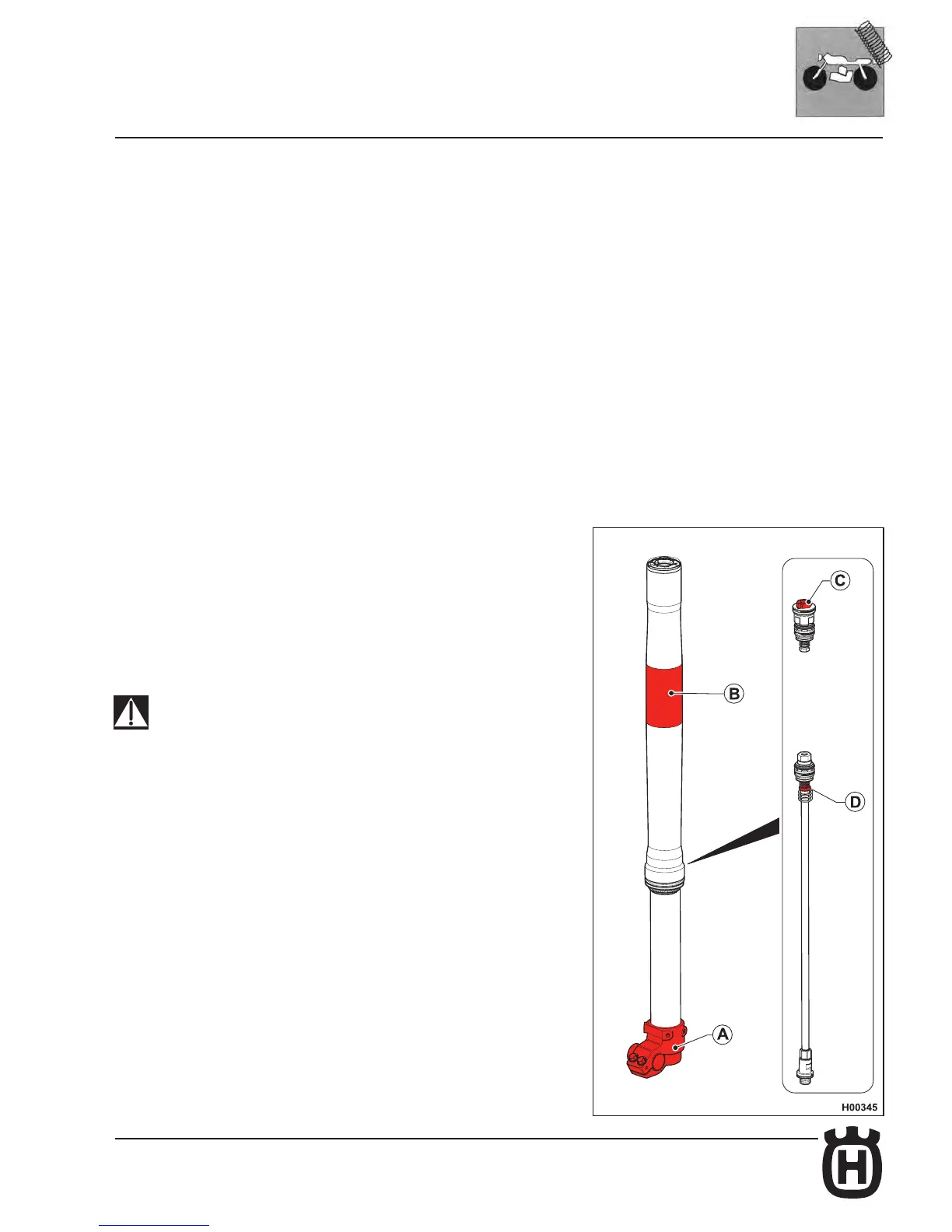

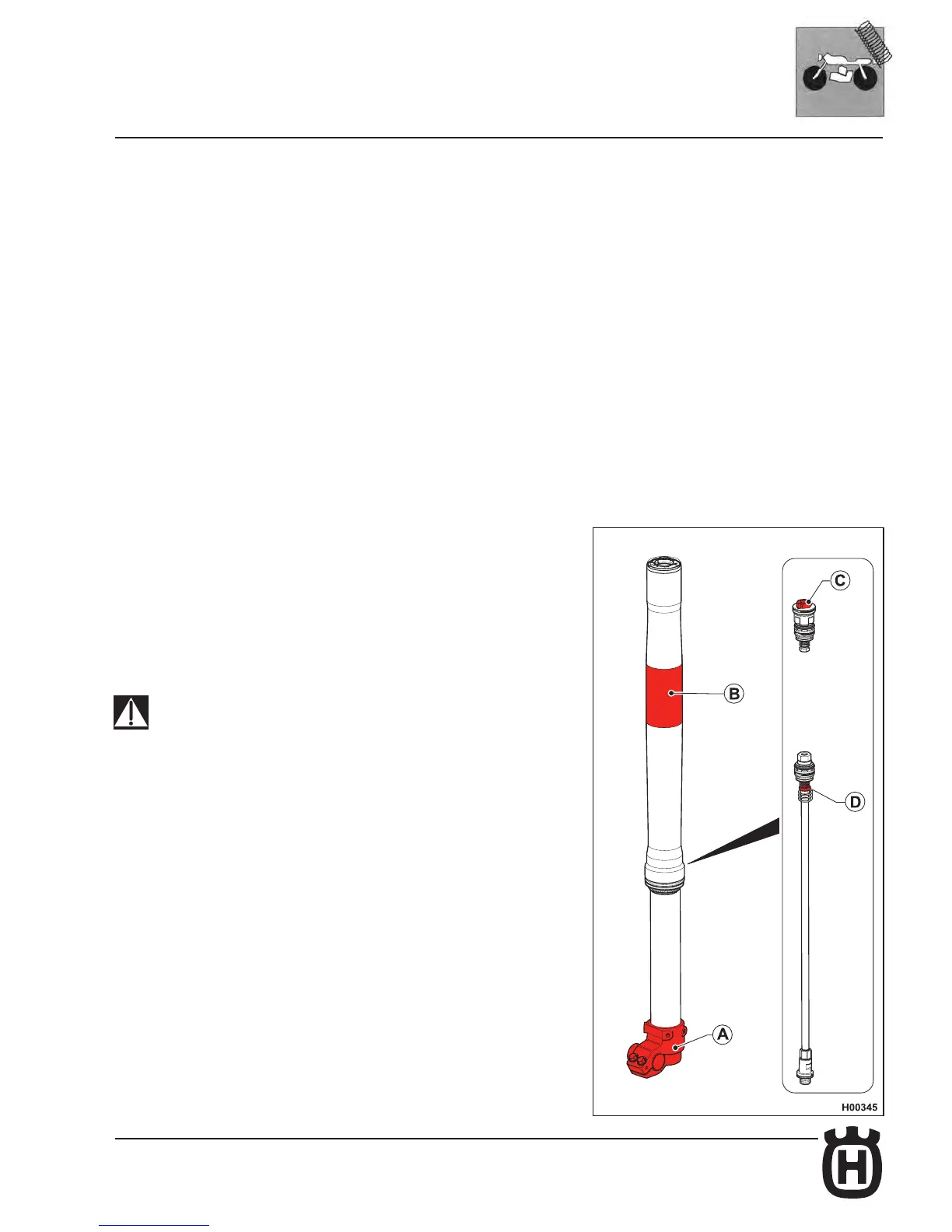

Placing the fork in a vice

Certain maintenance procedures may require clamping the fork in a vice in order

to tighten fork components.

WARNING

Improper use of a vice may cause irreparable damage to the fork, leading

to accidents, injury or death.

• Closely follow these instructions:

• Only use a vice when strictly necessary.

• Always use a vice with soft jaws.

• Do not overtighten when clamping the fork.

• Parts of parts that could damage and cause the suspension to malfunction

when out-of-round must never be clamped in a vice.

Fork areas that can be clamped in a vice are highlighted in the diagram.

A Wheel axle carrier.

B Outer tube area normally clamped in the bottom yoke.

C Compression valve nut.

D Cartridge, at tube spacer/case nut.

Loading...

Loading...