Oil lling.

Oil level cannot be measured. As a result, the fork must be lled with oil only

after complete disassembly (see par. 4.8).

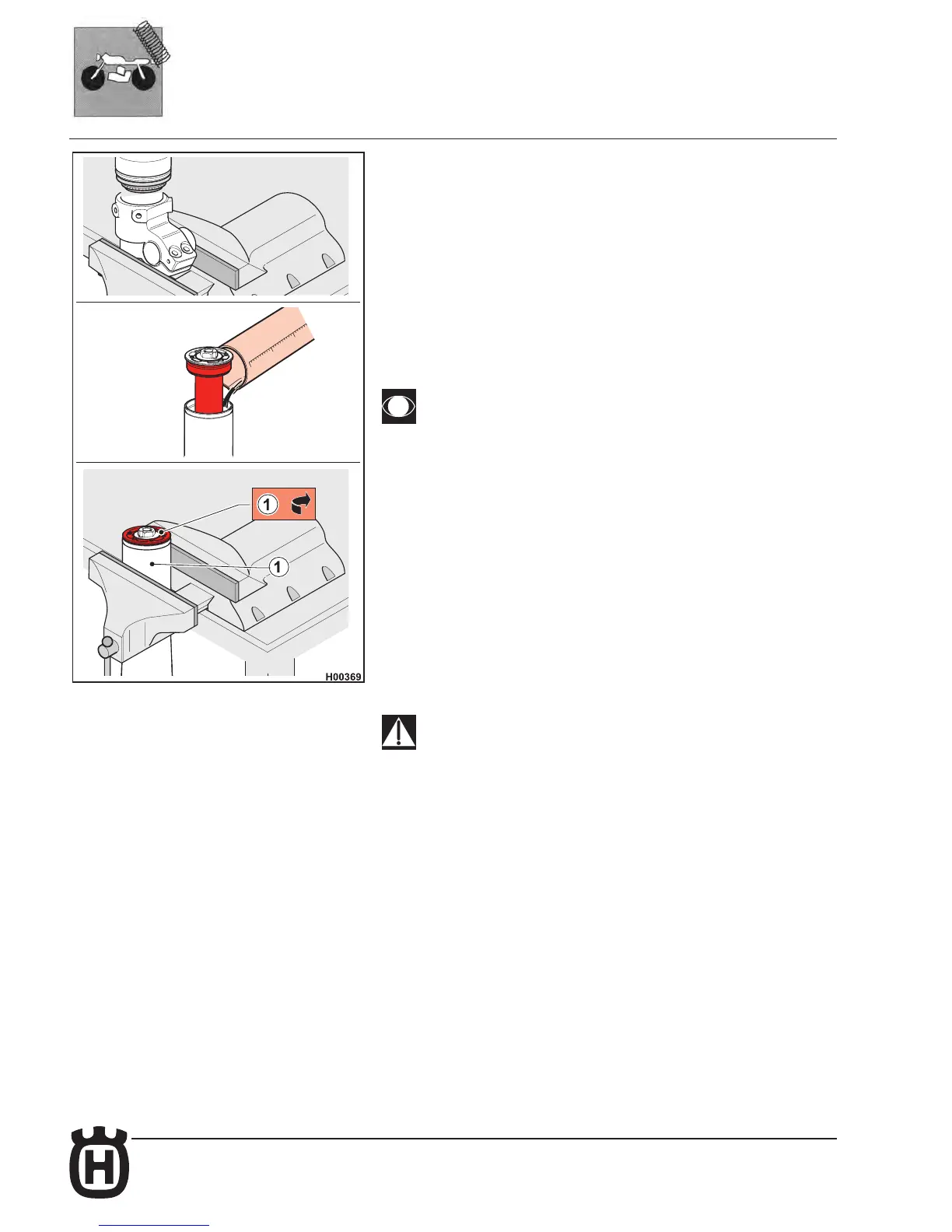

Clamp the fork leg in a vice in a vertical position.

Slide the outer tube over the inner tube up to 50 mm below the cap nut.

Prepare the quantity oil to be lled into the fork in a graduate.

OIL QUANTITY IN EACH FORK LEG:

310 cu cm

Pour the specied quantity of oil into the outer tube (11).

Using a quantity of oil or an oil type other than specied will alter fork

response.

Raise the outer tube fully over the inner tube.

Tighten the cap nut (1) onto the outer tube to the specied torque (see Tightening

Torque Figures table) using a 4 mm pin wrench.

Restore original settings (see page I.45).

Installing the fork on the motorcycle

WARNING

Fork installation must be in compliance with Husqvarna specications for

steering, braking system and wheel installation. Improper installation may

put the safety of the rider at risk.

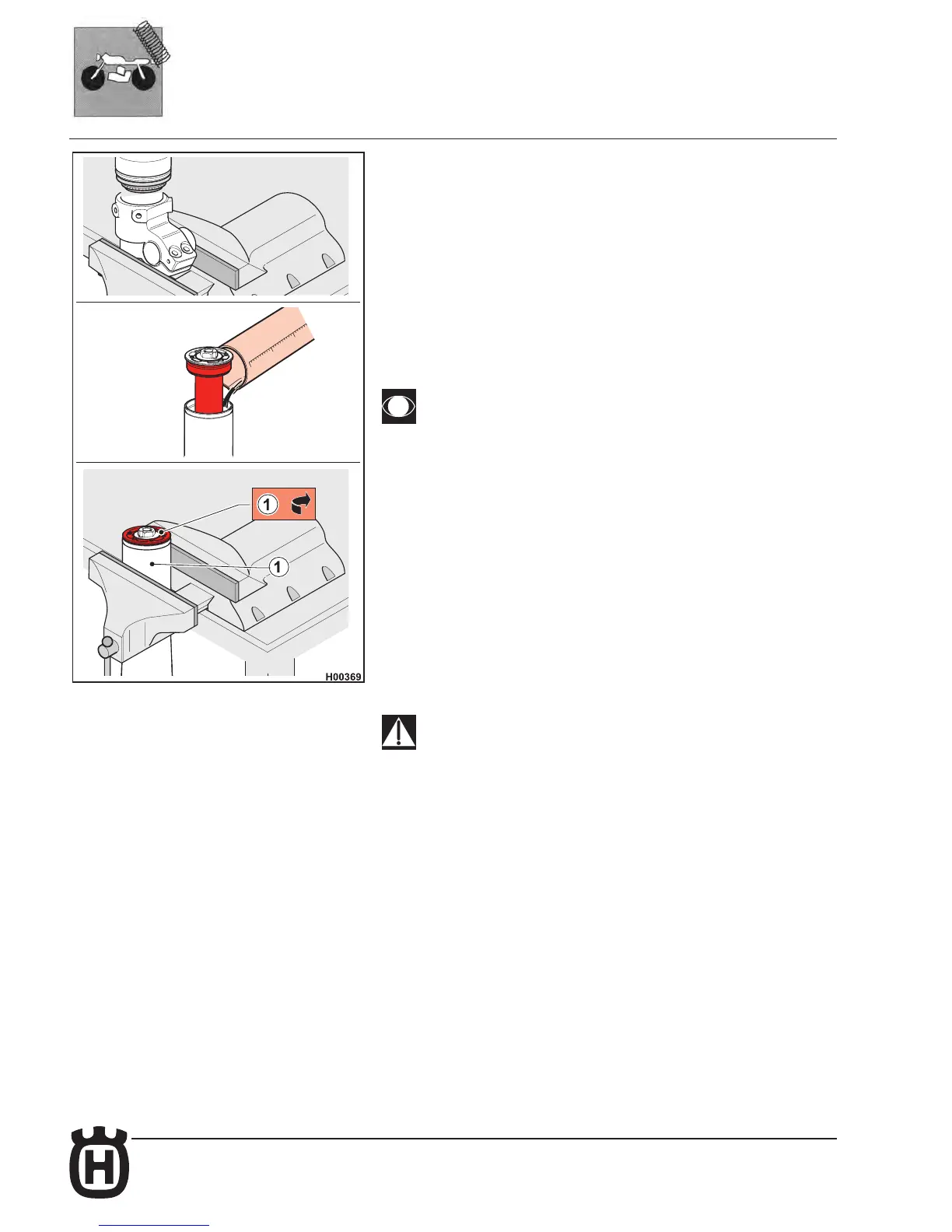

For correct fork operation, the wheel must be installed on the fork as follows:

Slide the axle through right-hand axle carrier, wheel and left-hand axle carrier.

Install the axle nut on the left-hand side and tighten fully.

Tighten the two left-hand carrier screws following a 1-2-1 sequence (see Tight-

ening Torque Figures table).

Pump the forks to full travel several times.

Tighten the two right-hand carrier screws following a 1-2-1 sequence (see Tight-

ening Torque Figures table).

Loading...

Loading...