Wheel servicing

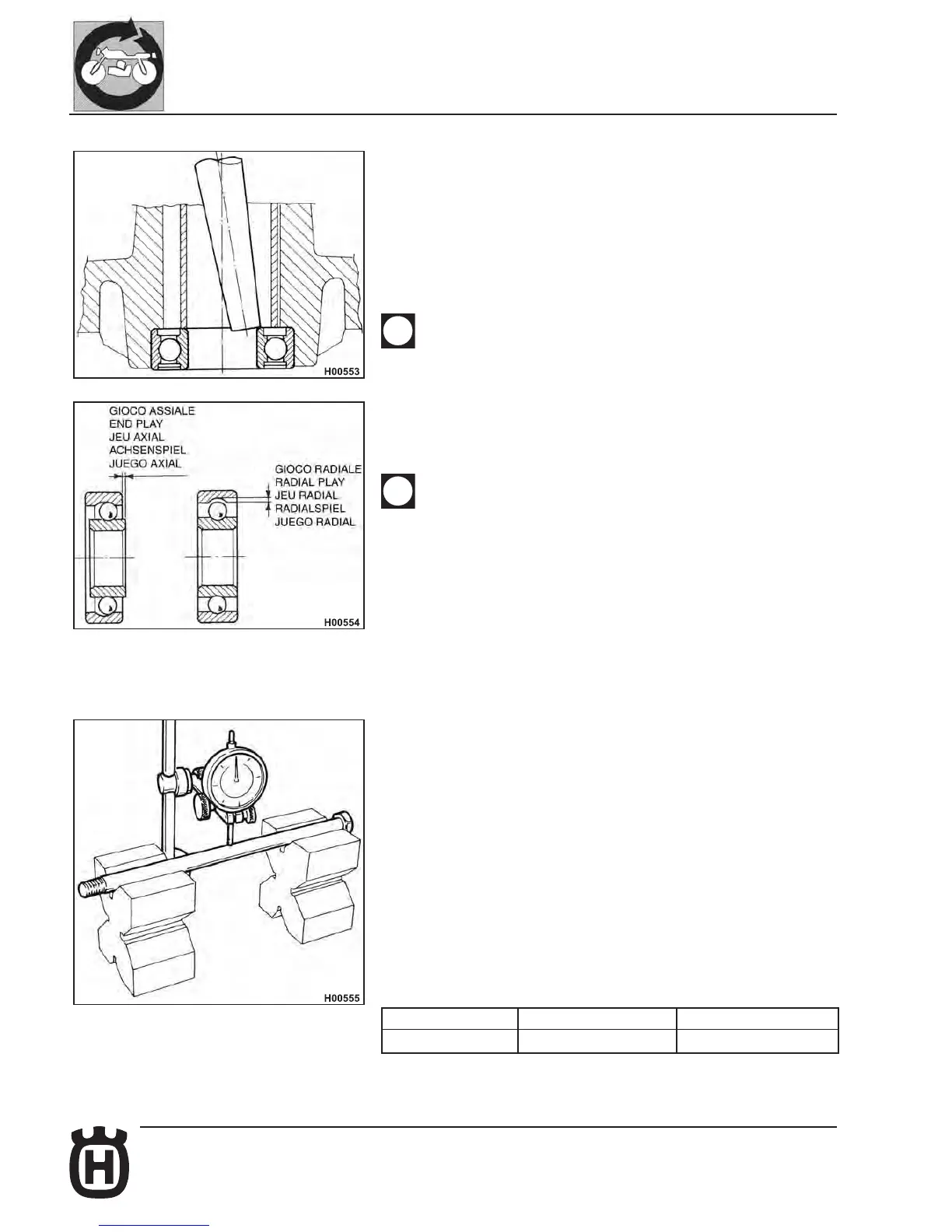

Check the wheel hub bearings for wear. If you nd too much (radial or axial)

clearance, replace the bearings as follows:

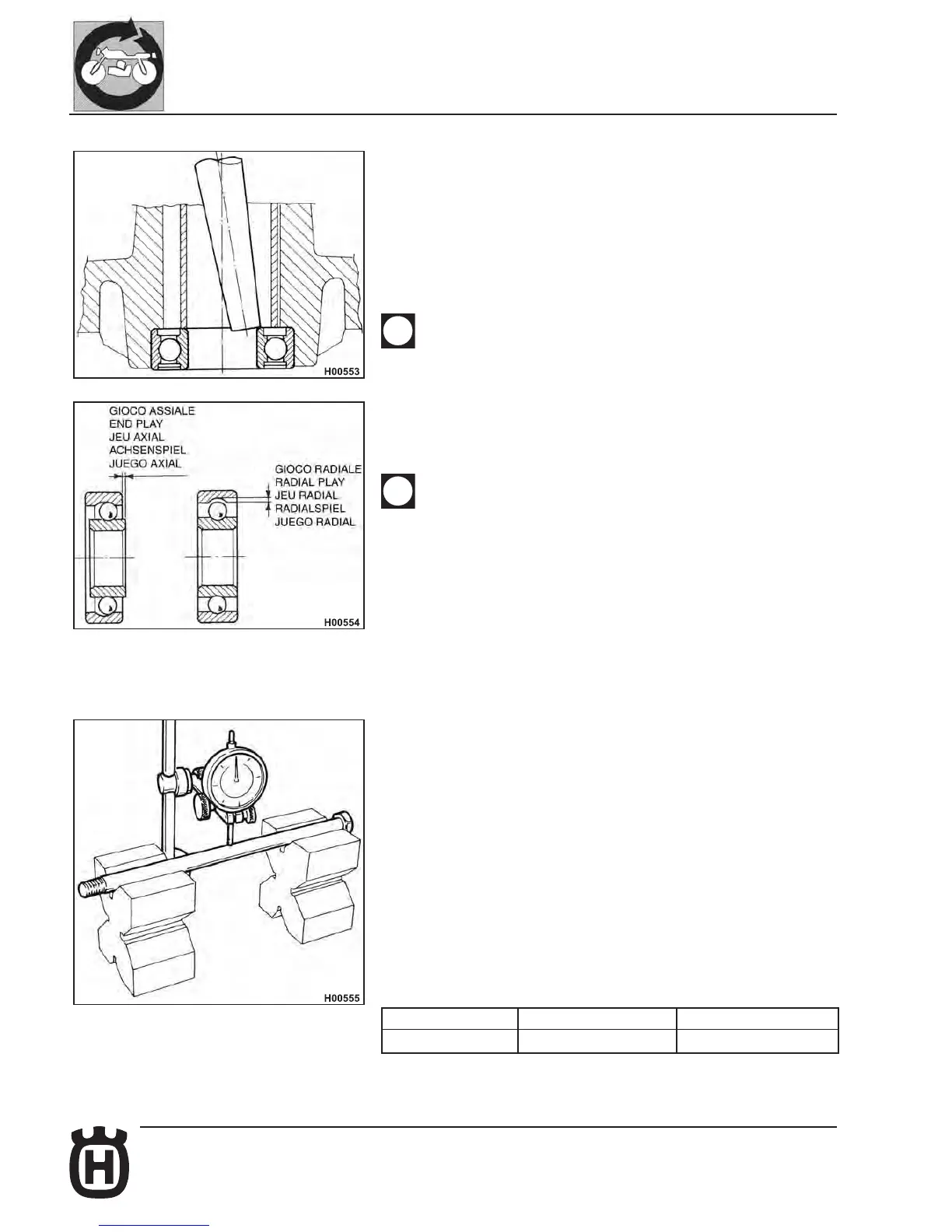

- place the hub on a at surface with an appropriate hole (for when you knock

out the bearing);

- use a hammer and a punch to knock out the bearing; apply pressure only on

the inner race of the bearing (see gure);

- tap at different positions so as to keep the bearing square in its seat;

- remove the spacer and use the same procedure for the other bearing.

Discard the bearings after removal. Never reuse them.

Before installing the new bearings, check to ensure the seat is clean and shows

no grooves or scratches. Lubricate the seat before installing the bearing. Drive

the bearing into place using the special installer that only applies pressure to the

outer race. Fit the spacer and the other bearing. Check for perfect alignment as

you slide the axle into place.

Wheels should be balanced after each service.

Wheel axle warpage

If warped beyond the maximum limit allowed, the axle must be straightened or

replaced. Replace the axle if it cannot be straightened so as to meet the maxi-

mum limit allowed.

Axle runout over 100 mm

Wheel axle Standard Max limit

Wheel axle less than 0.1 mm 0.2 mm (0.0078 in.)

Loading...

Loading...