Apply Loctite and screw on the reservoir being careful not to damage the O-ring.

Tighten to 40 Nm (4 kgm; 39.2 ft/lb).

NOTE: Perform these procedures in a clean environment and clean any com-

ponents to be reused.

Floating piston removal

If you have drained the shock oil, you will need to remove the oating piston.

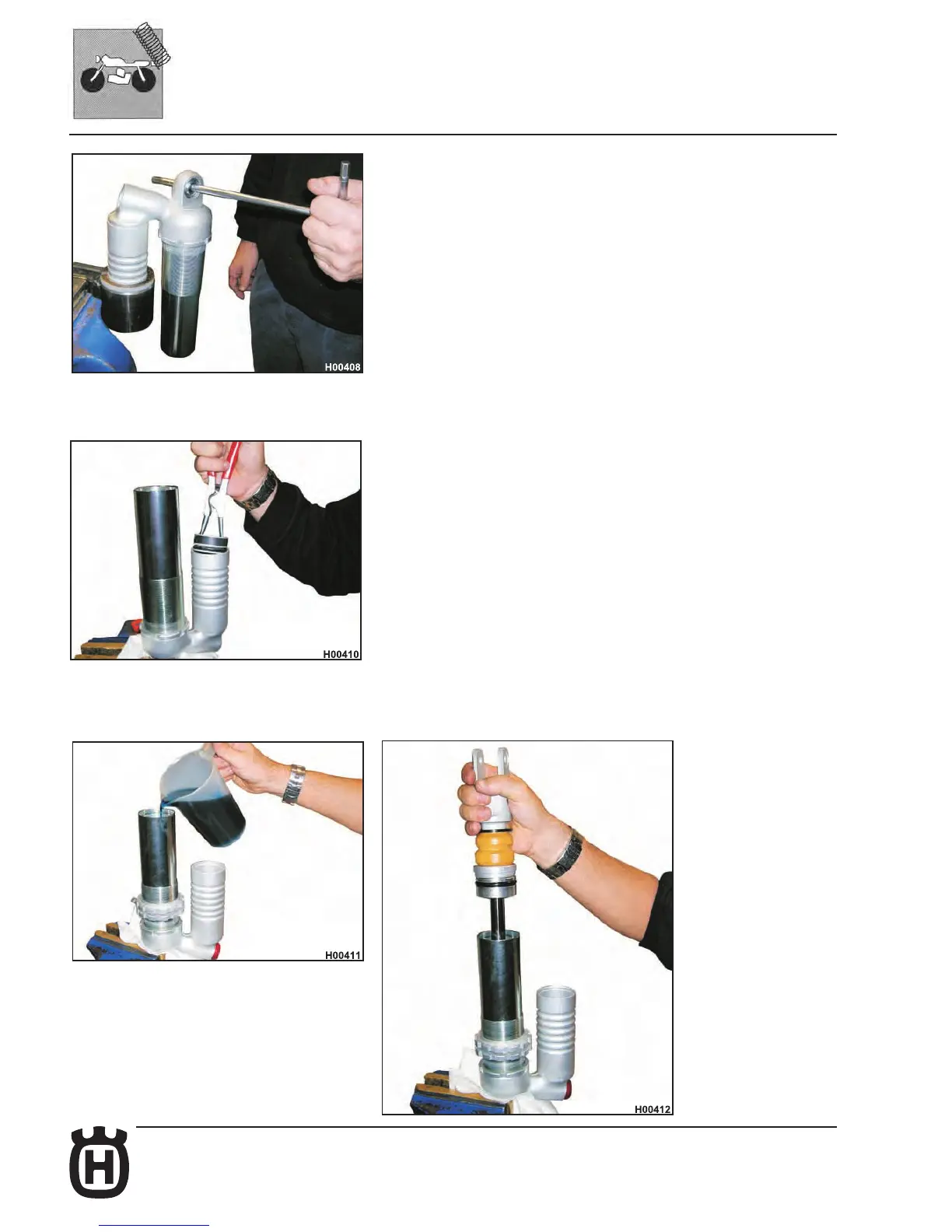

Extract the oating piston using pliers and be careful not to score the reservoir.

Replace the reservoir if it shows any surface damage.

Shock absorber assembly

Wash the shock absorber body thoroughly with a degreasing product. Make sure

it is fully dry. Blow with compressed air if needed.

Clamp the shock absorber eye in a vice with aluminium or bronze jaws (or use

a shop rag to protect the eye). Fill 70-80 cu cm (4.3-4.9 cu. in.) of oil into the

shock absorber body. Insert the complete piston rod into the shock absorber

body, taking care not to damage the sliding surface; push rod with piston and

mount, but leave a gap to top up with oil later.

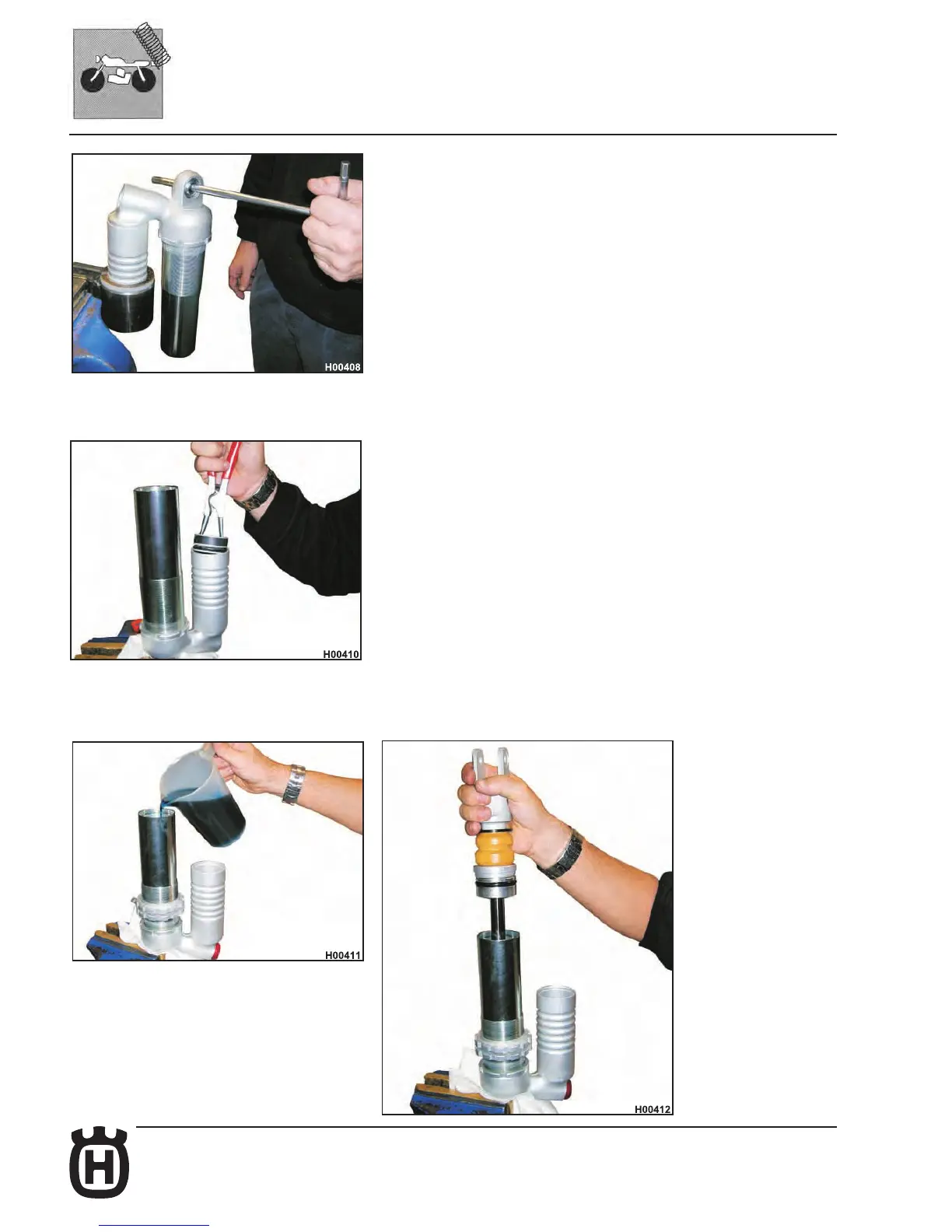

Fit a new O-ring to the oating piston (always use a new O-ring after removal).

Fill the reservoir with oil, then quickly insert the oating piston into the reservoir

(see picture).

Loading...

Loading...