10-9

Positioning workpieces for stage and

robot applications [Alignment Func-

tion]

An FH/FHV series Controller has an alignment function that you can use to position workpieces for

stage and robot applications (hereafter called external devices).

Alignment executes a combination of more than one processing item.

This section gives an overview of alignment, and provides details on its use in general.

Refer to Vision System FH/FHV Series Processing Item Function Reference Manual (Cat. No. Z341)

for details on the processing items that are used for alignment.

10-9-1

Overview

An FH/FHV series Controller measures the position of alignment marks on the workpiece, or the posi-

tion of specific features of the workpiece (such as corners), and outputs the axis movement to a PLC

or stage controller, which aligns the workpiece into a specified position (hereafter called the reference

position).

The PLC or stage controller simply needs to send a movement command to the external device for the

axis movement amount that was output from the FH/FHV series Controller to align the position of the

workpiece.

The following two measurement flows are used to perform alignment. Set both flows for each scene.

• Calibration flow:

This flow associates the coordinates of the external device with the Camera coordinates.

• Alignment flow:

This flow uses the calibration parameters that were created in the calibration flow to align the posi-

tion of the workpiece.

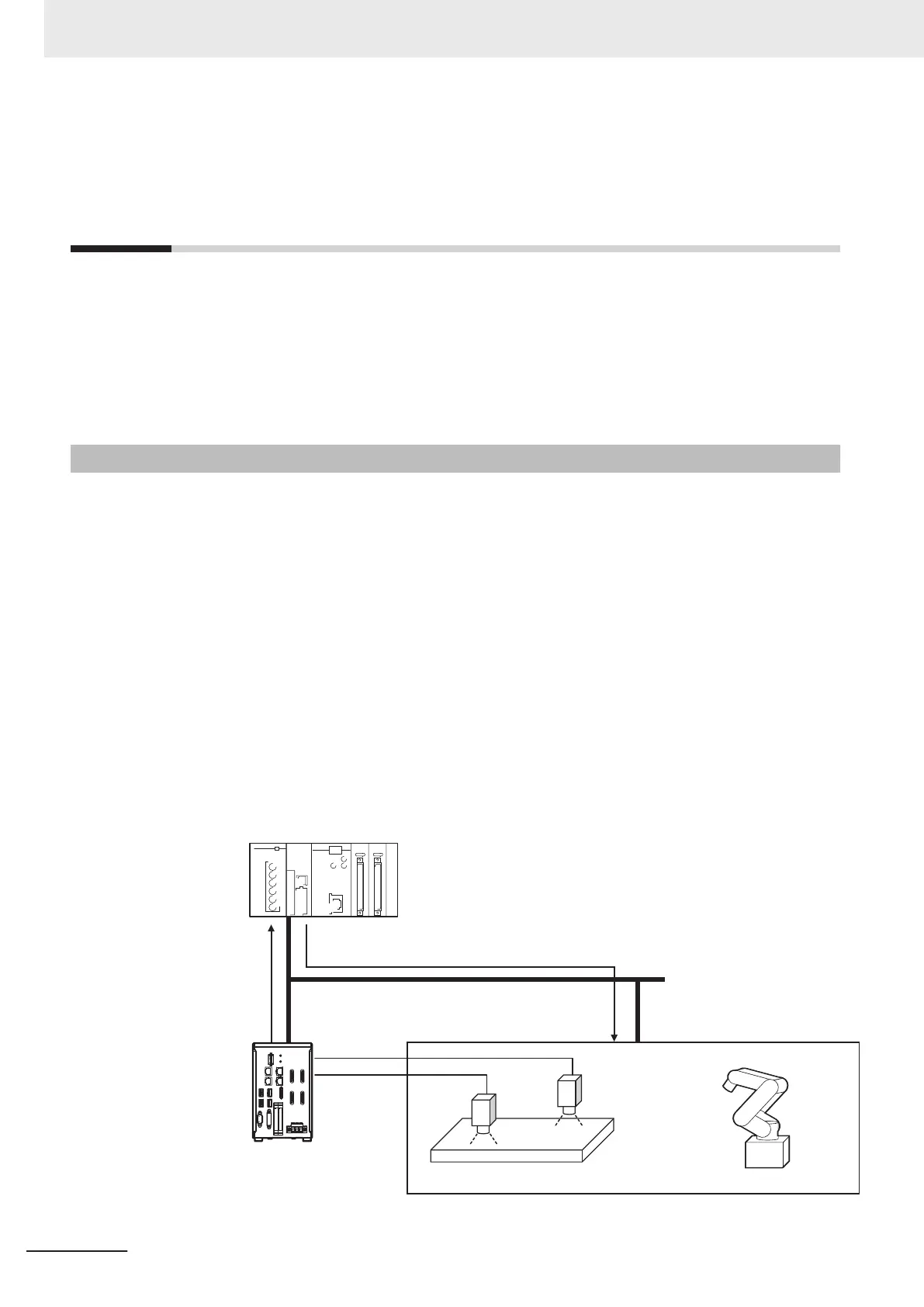

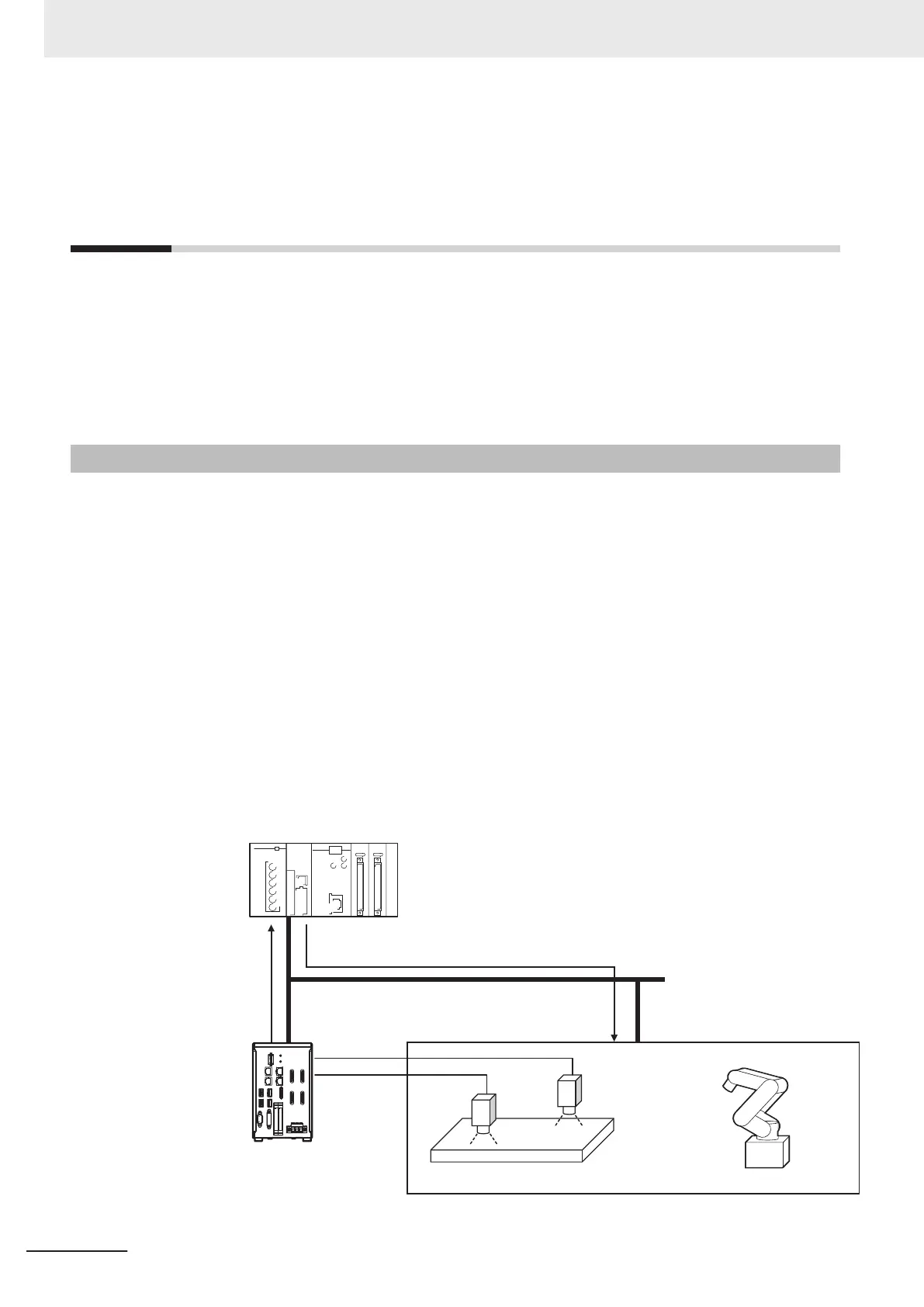

PLC

Sensor Controller

Stage Robot

Or

Movement command (stage or robot coordinates)

Required move-

ment (stage or

robot coordinates)

Conversion of stage or

robot coordinations from

Camera coordinates

10 Advanced Usage

10 - 52

FH/FHV Series Vision System User’s Manual (Z365-E1)

Loading...

Loading...