Setting item Description

Upper

Lower

Specify the upper and lower limits of defect detection size based on the size of

scratch or contamination to be detected.

The larger the difference between upper and lower limits, the easier it is to detect

the scratches or contamination of various sizes.

For both upper and lower limits, higher values for defect detection size limits leads

to weaker detection sensitivity and shorter processing time.

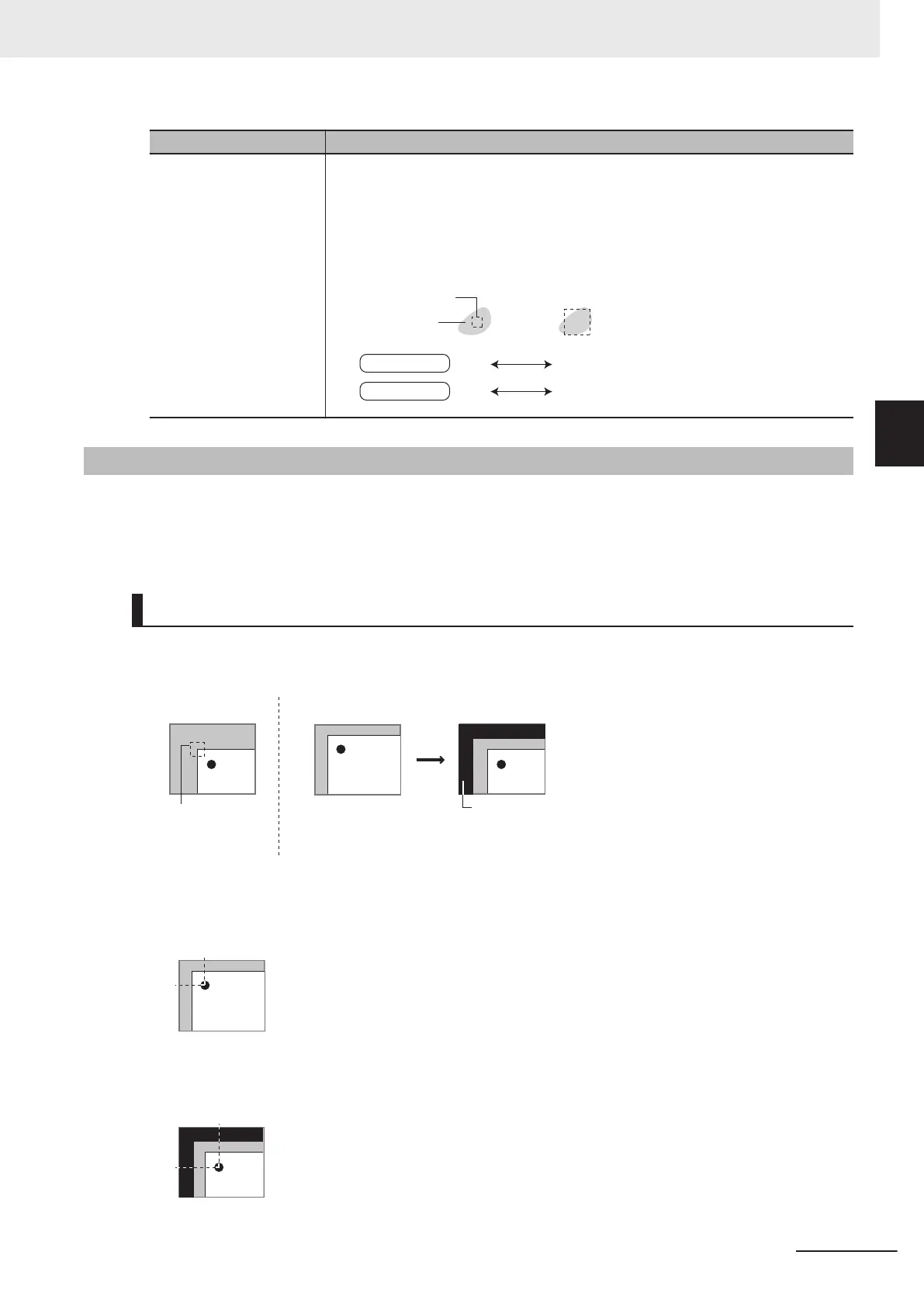

Sensitivity high low

Defect detection size

Defects

Processing time

long short

A-5-5

Handling Coordinates

The processing items for measuring positions have a setting item called Output parameter with which

you can select how to handle coordinates.

In Output parameter, you can set Output coordinates and Calibration.

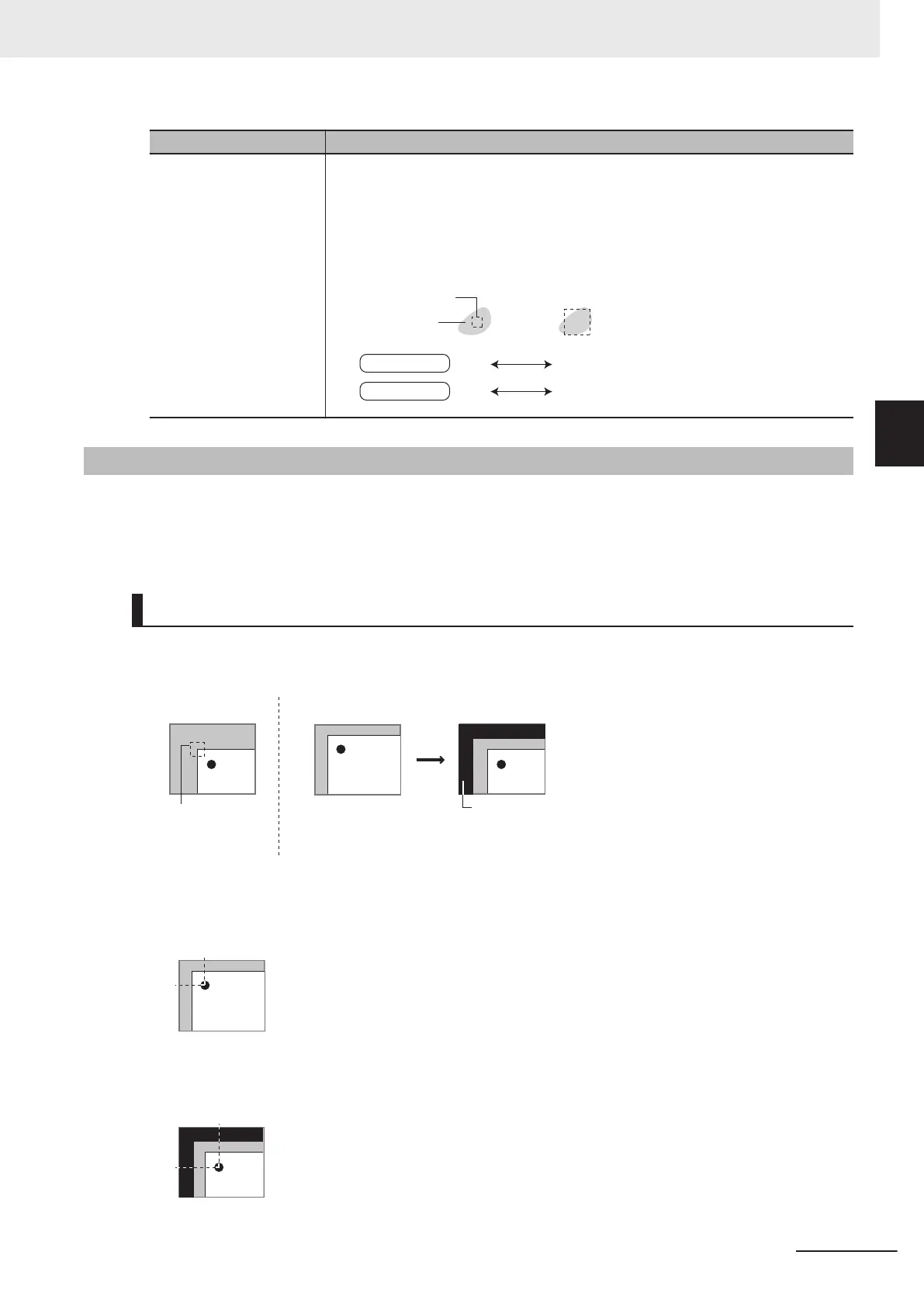

Output Coordinates

Selects coordinate types to be output to external devices.

Example)

This angle is used as

model for position

compensation

The area outside of

imaging range is turned

into black

Measurement image

(image without position

compensation)

Image with position

compensation

(for left upper deflection)

Image when setting

Reference position

• Before position compensation:

Coordinate values before position compensation are output.

• After position compensation (with factory settings):

Coordinate values after position compensation are output.

Appendices

A - 19

FH/FHV Series Vision System User’s Manual (Z365-E1)

A-5 Measurement Mechanism

A

A-5-5 Handling Coordinates

Loading...

Loading...