SmartPAC 2 User Manual 1126700

Installation 2-39

7. Press RESET twice to return to the Main Program Menu.

8. Create a tool, following the steps in Creating a New Tool, page 5-3.

9. Enter a counter preset of 10,000 for the tool, following the directions in COUNTERS,

page 5-9.

10. Load the tool, following the instructions in Loading a Tool, page 5-5.

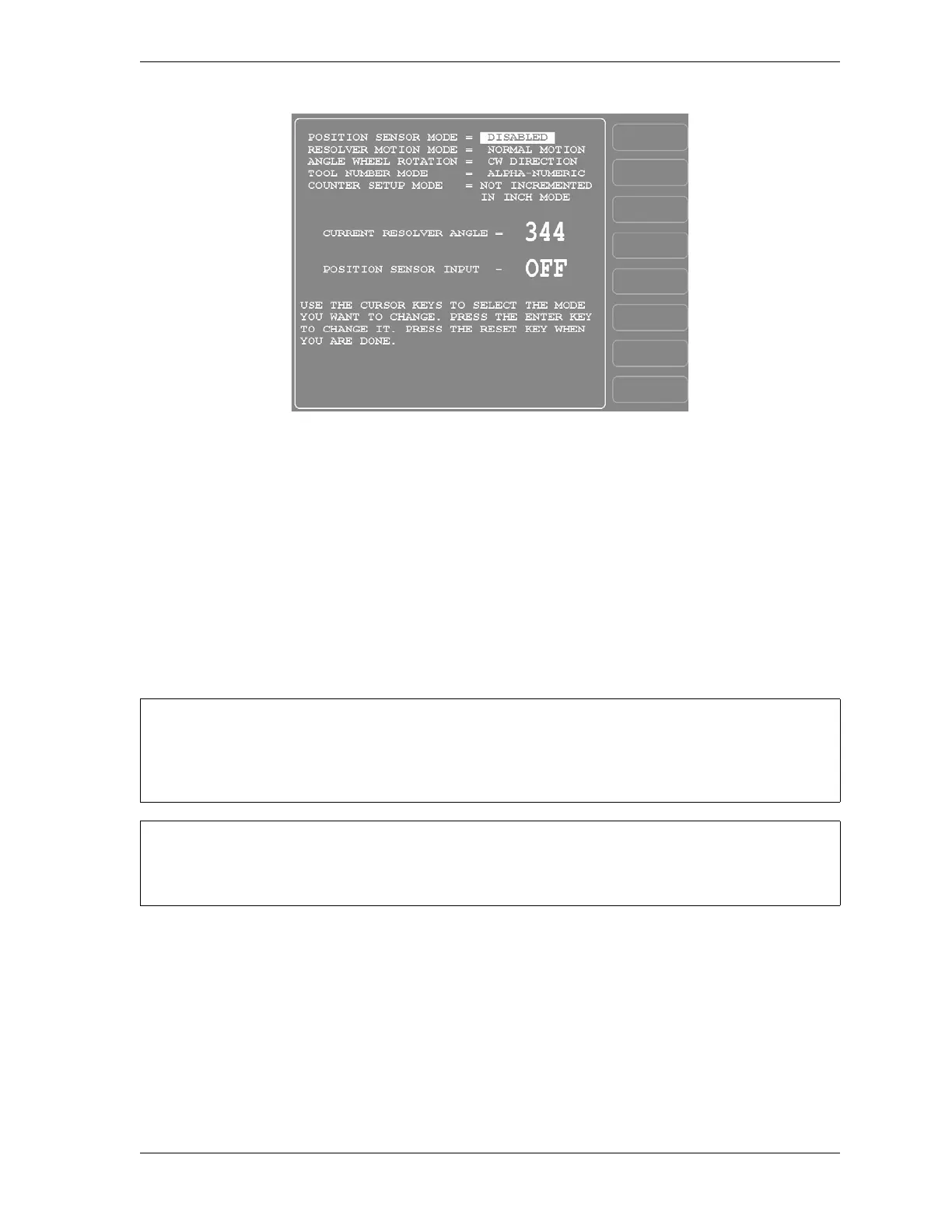

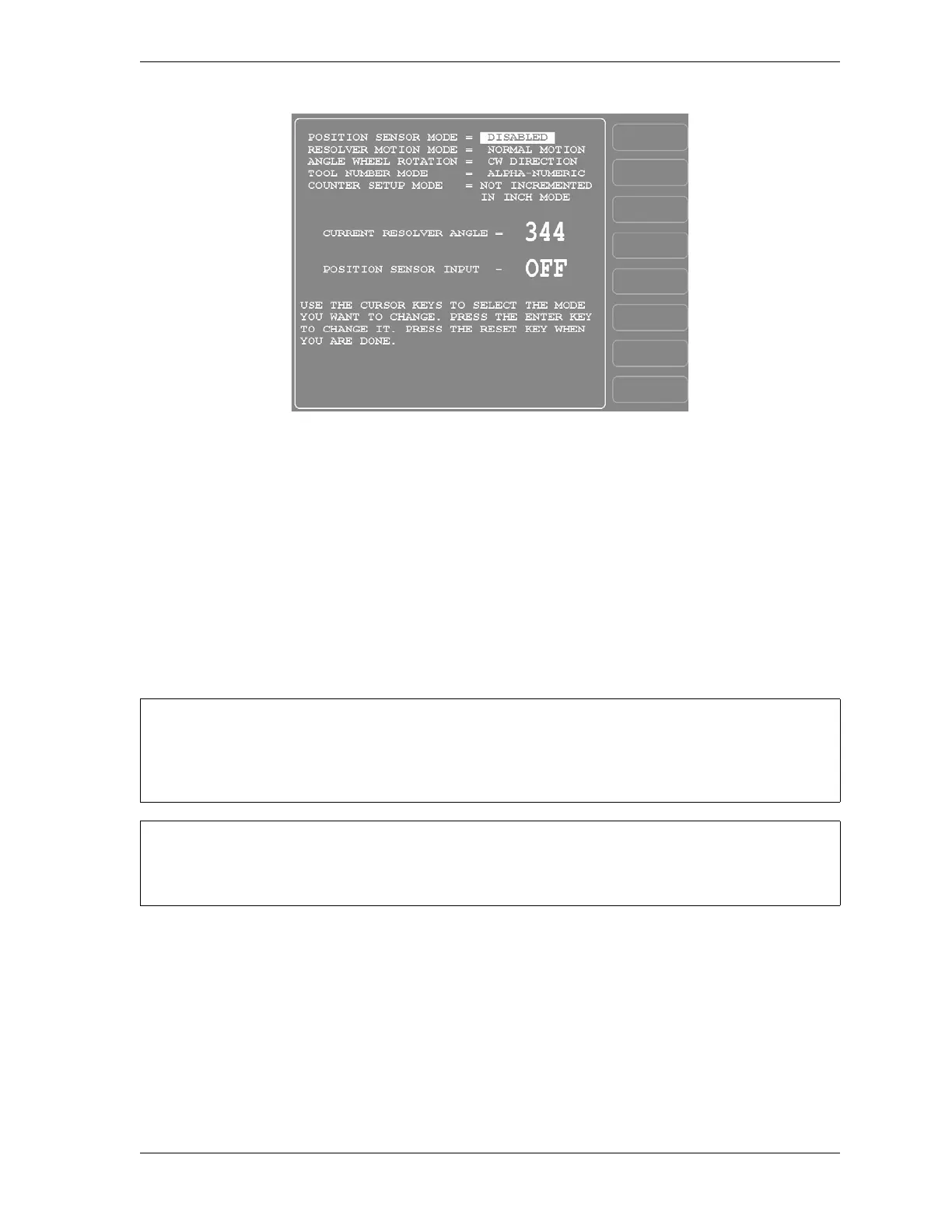

11. Access the Position Sensor screen again (see steps 4 and 5).

12. Check the CURRENT RESOLVER ANGLE setting. If it is not zero (0), inch the press

until it reads zero.

13. Shut off power to SmartPAC 2 and the press control.

14. Mount the magnetic switch so that the magnet rotates 1:1 with the crankshaft of the press.

The ideal location is on the crankshaft itself. However, you might also use the Pitman

above the adjusting screw or a drive shaft to a feed or other device. See Figure 2-1,

page 2-4 and Figure 2-27, page 2-40.

15. Temporarily mount the magnet, plastic side up, so it is centered beneath the magnetic

switch as shown in Figure 2-27.

Figure 2-26. Position Sensor Screen

The crankshaft angle reading should increase as you inch the press. If it decreases (359°, 358°,

357°, for example), swap the black and yellow wires (terminals 213 and 216) on connector TB101

on the SmartPAC 2 board (see Figure 2-7 and Table 2-1, page 2-13).

The press must be at top dead center (0°) before the position sensor can be installed. Make sure

that the CURRENT RESOLVER ANGLE setting is 0° before proceeding to the next step.

Loading...

Loading...