Appendices

A - 18

Vision System FH/FHV/FZ5 Series User’s Manual (Z365)

Color changes within the measurement region are used to find defects such as scratches,contamina-

tion, and chipping.

After measurement region is drawn, a rectangle (defect detection region) is automatically formed in this

region. While moving the defect detection region around, calculate average density for each area to

determine the difference between the original area and the surrounding area. This difference is called

the defect level. Calculate the defect level for all defect detection areas. If the maximum value exceeds

the judgement value, it is judged that there are defects in the measurement region.

Increasing "Defect size" allows for shortening of processing time, but this will reduce measurement

accuracy.

A-5-4 Defect Detection Measurement

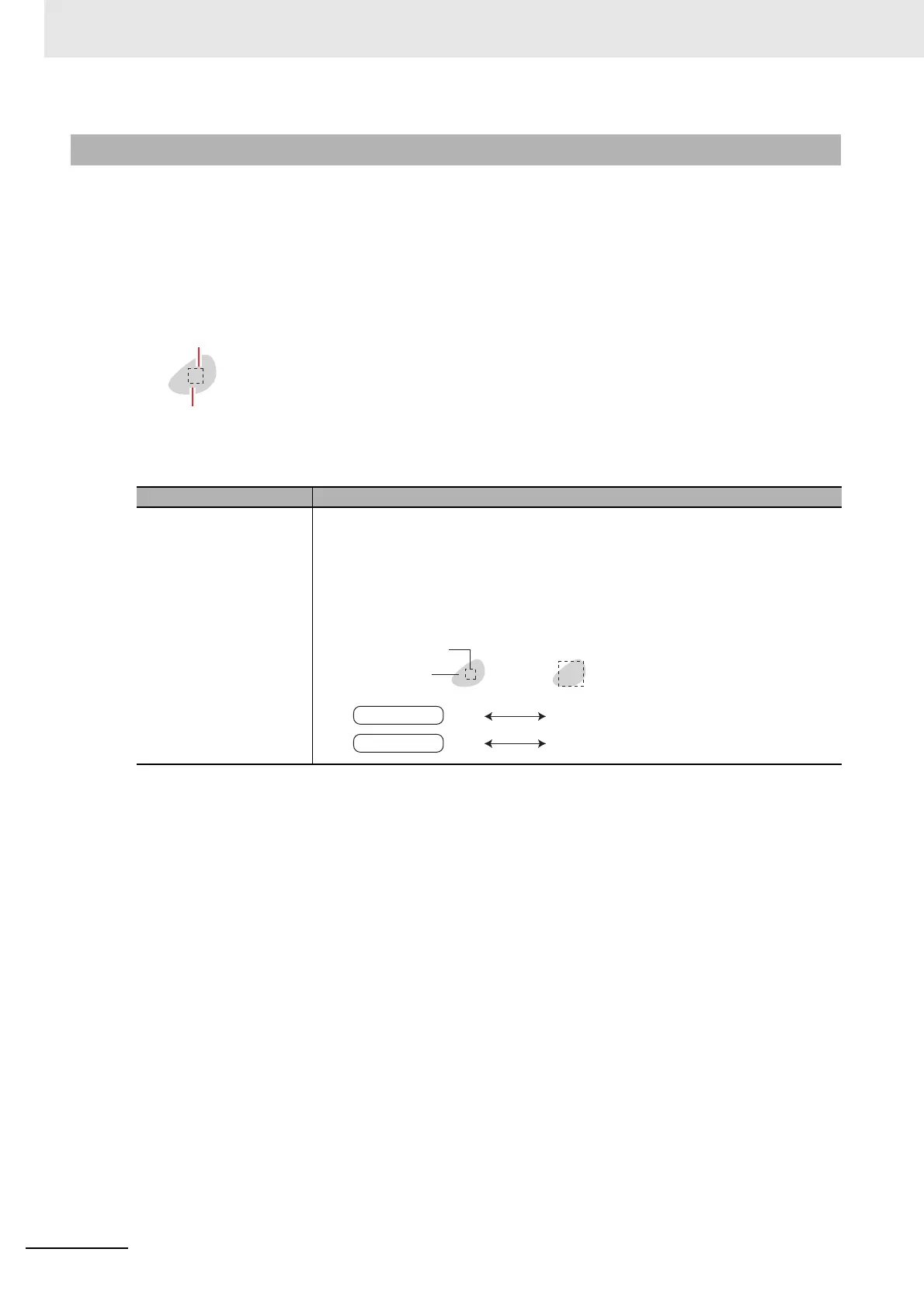

Setting item Description

Upper

Lower

Specify the upper and lower limits of defect detection size based on the size of

scratch or contamination to be detected.

The larger the difference between upper and lower limits, the easier it is to detect the

scratches or contamination of various sizes.

For both upper and lower limits, higher values for defect detection size limits leads to

weaker detection sensitivity and shorter processing time.

Defect detection size

Defect

Sensitivity high low

Defect detection size

Defects

Processing time

long short

Loading...

Loading...