v 1.0 — February 2020 Altanium Matrix5

102 Abort Conditions — Shutdown Errors

9.8 Abort Conditions — Shutdown Errors

Abort conditions are shown on the Alarms screen and the Event History screen. The

conditions listed in Table 9-7 cause audible and visual alarms. Because they are shutdown

errors, they will cause a zone or system shutdown condition controlled by the PCM settings.

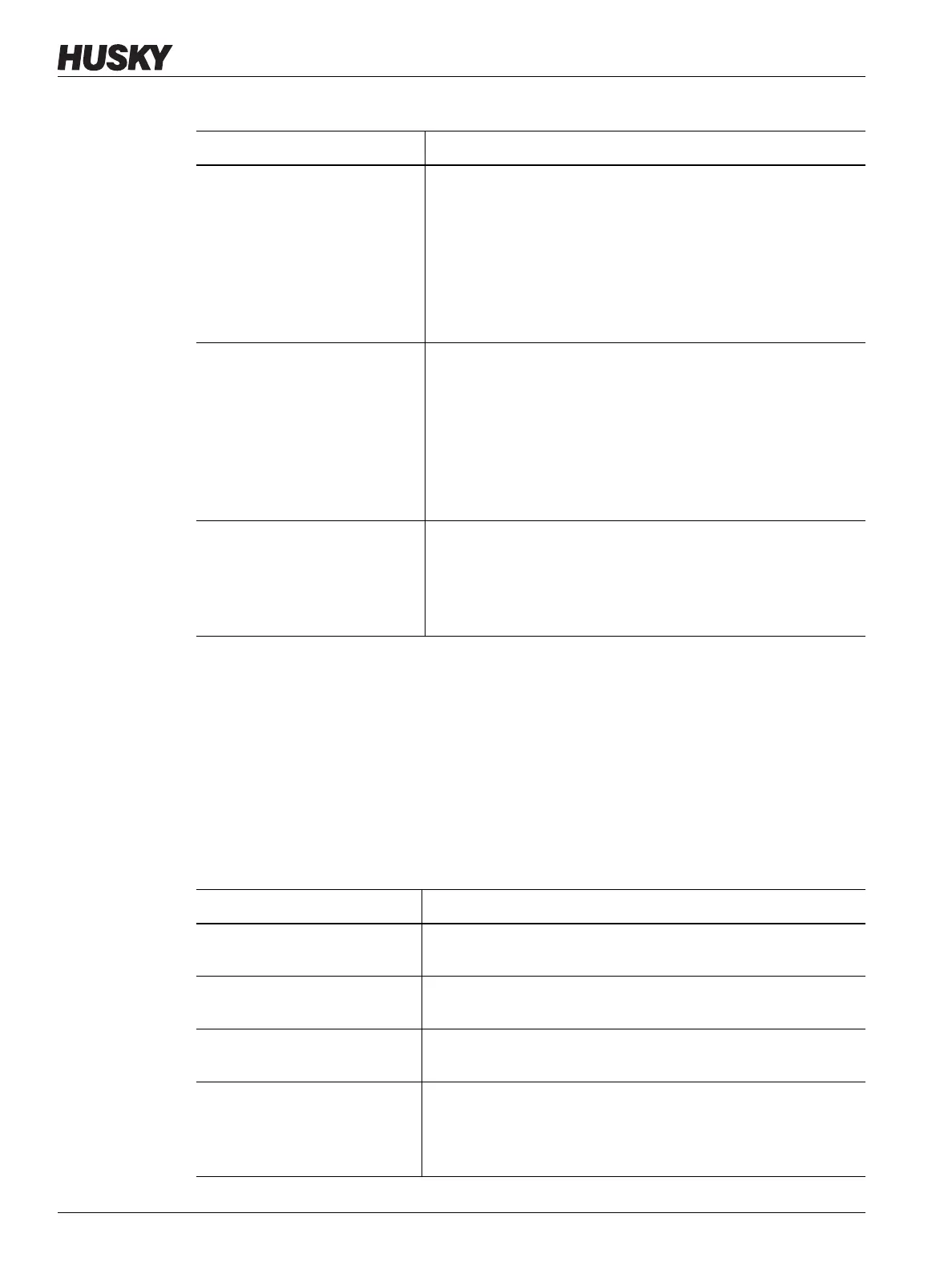

Auto Slave Enabled A zone’s thermocouple has become defective as the system

operates in automatic control mode. The system has

automatically slaved this zone to a different zone with the use of

data it collected before the thermocouple became defective.

The zone with the defective thermocouple becomes controlled

by the power output from a similar zone. The master zone

number is shown in the Slave to Zone field of the defective zone

on the Quick Set screen.

AMC Active A zone’s thermocouple has become defective as the system

operates in automatic control mode. There was no match found

for this zone in the mold by the Auto-Slave feature or the Auto-

Slave feature is OFF. The zone has been set to go into Automatic

Manual Control (AMC) in this event. The zone is now controlled

in manual mode at a power percentage selected by the

controller with the use of data it collected before the

thermocouple became defective.

Power Deviation The zone’s power output value has deviated by an amount

calculated by the power deviation algorithm. The power

deviation algorithm uses calculation factors, which include a

historical power average, heater type, changes to the power

supplied to the unit, and other values.

Table 9-6 Warning Errors (Continued)

Warning Description

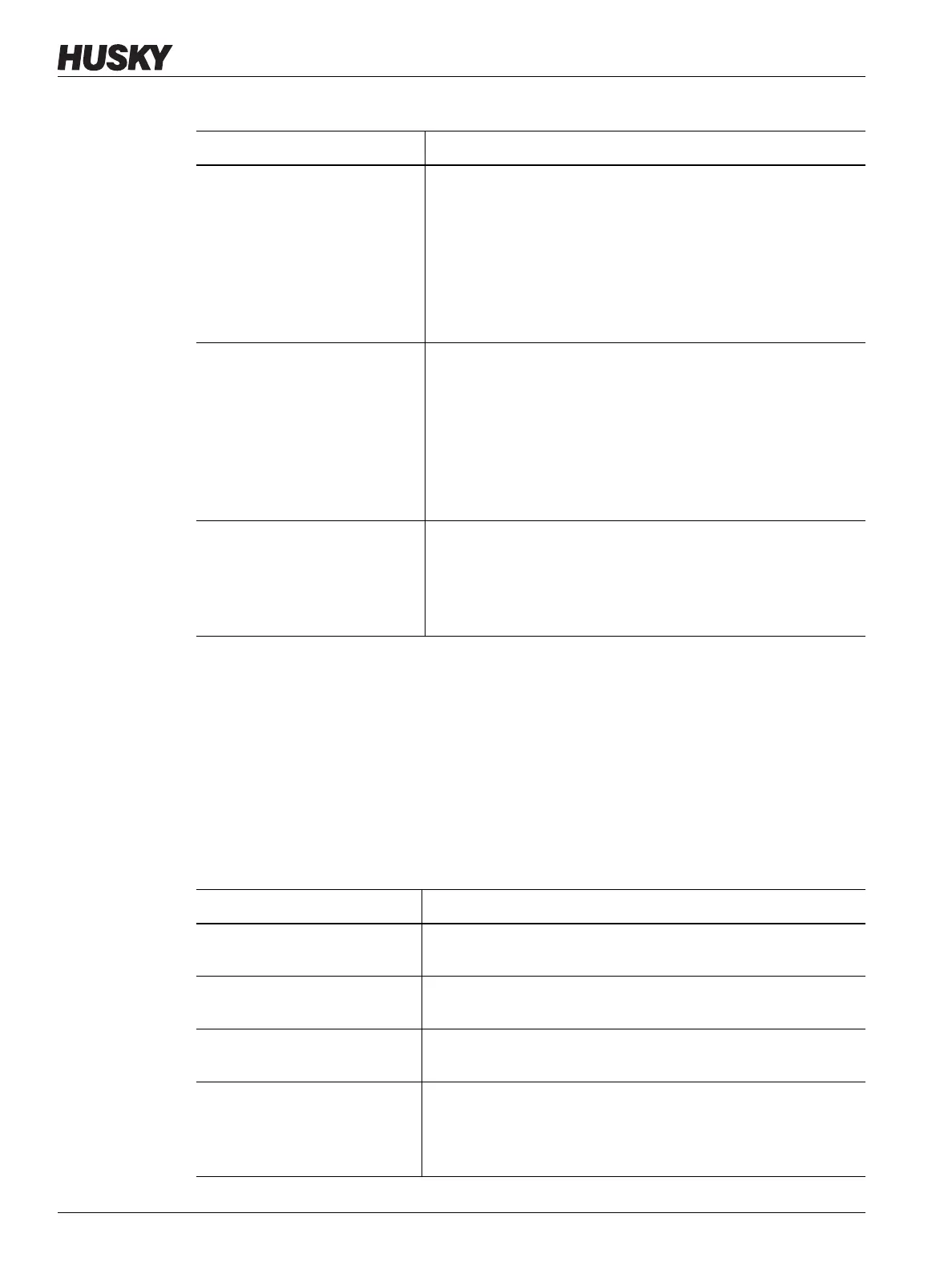

Table 9-7 Shutdown Errors

Shut Down Error Description

Abort Over Temp A zone's actual temperature is more than its setpoint by the

degrees set in the Abort Window field on the Quick Set screen.

Abort Under Temp A zone's actual temperature is less than its setpoint by the

degrees set in the Abort Window field on the Quick Set screen.

Circuit Overload The current on this zone has increased above the maximum

value for current deviation.

Configuration Each zone’s control parameters are compared to the values sent

and received by each zone. If the values are different, the system

automatically corrects the problem. If the problem is not

corrected after one minute, the configuration alarm is triggered.

Loading...

Loading...