Grove Published 7-23-2020, Control # 668-02 5-29

GRT9165 OPERATOR MANUAL SET-UP AND INSTALLATION

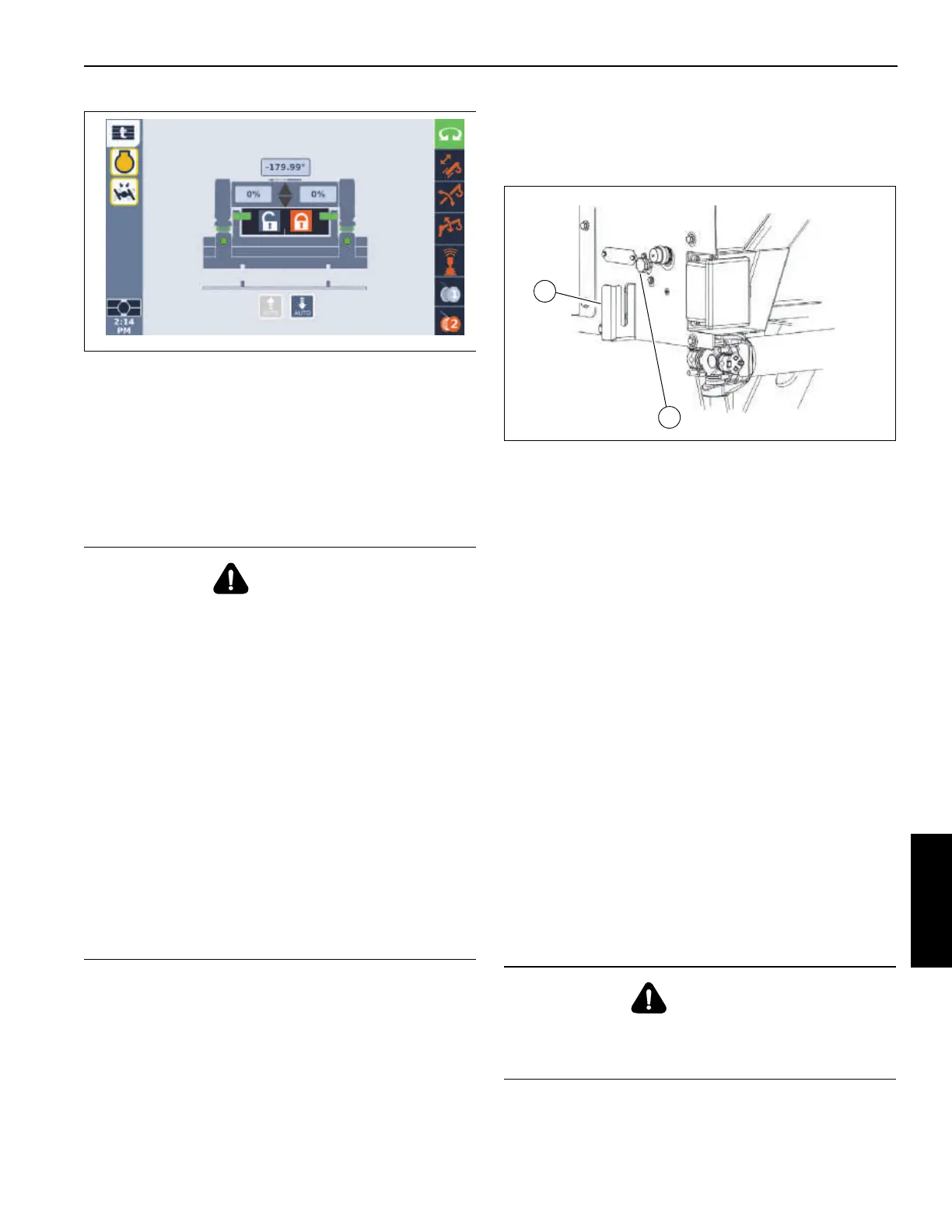

When the locking pins are locked, the counterweight is

installed.

14. Update the RCL code as needed for a configuration that

includes the counterweight. For more information, see

Enter Rigging Code, page 4-159.

OUTRIGGER REMOVAL AND

INSTALLATION

Bleed Valve Operation

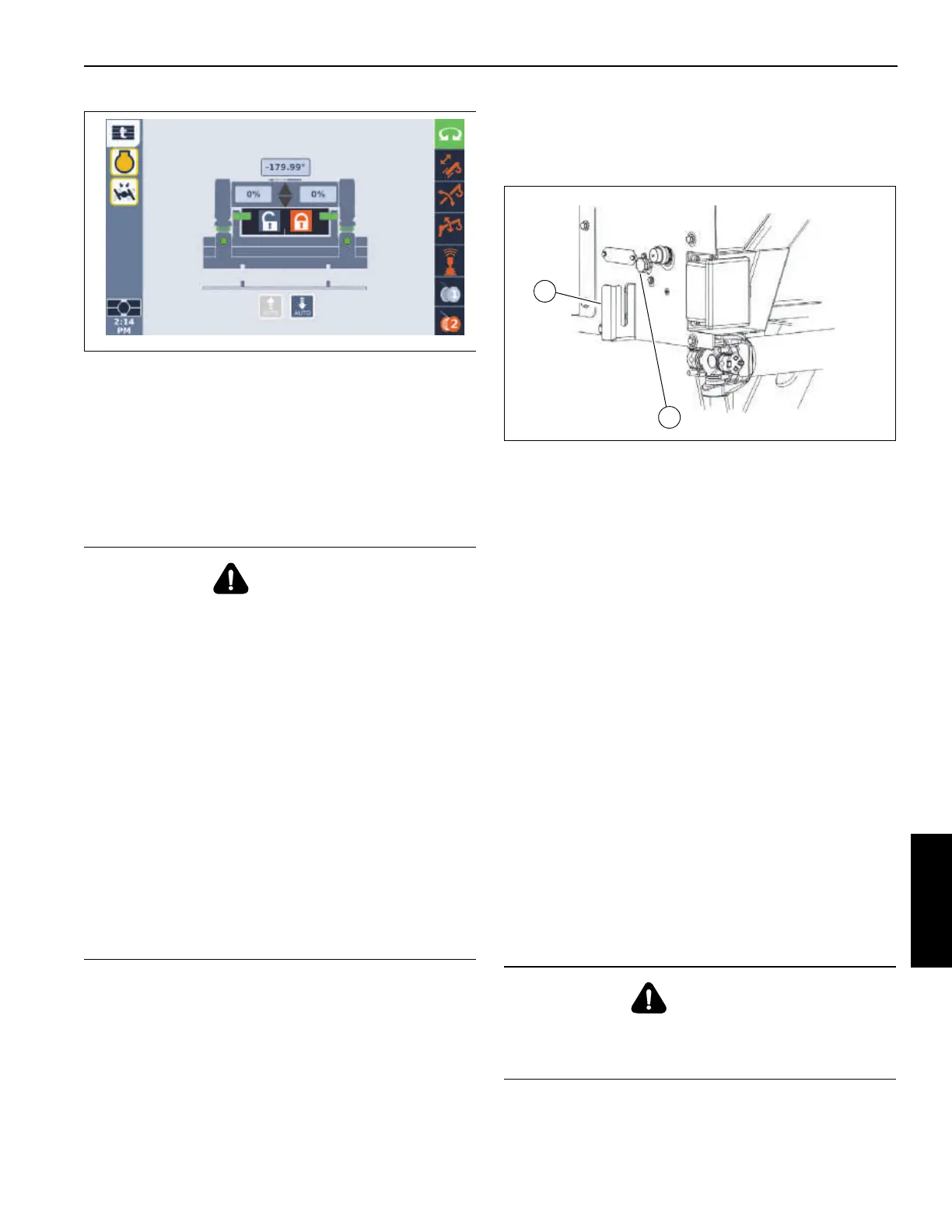

The manual pressure bleed valve (1, Figure 5-17) is located

on the back of the right rear fender. The purpose of the valve

is to reduce the effort required to separate and connect the

hydraulic quick disconnect couplers when removing or

installing the front and rear outrigger boxes.

The hydraulic hoses on each outrigger box also feature

bleed fittings (9, Figure 5-19). Use these bleed fittings relieve

pressure when installing the outrigger box after the box has

been sitting in the sun.

1. Shut off the engine.

2. Turn the handle counterclockwise to open the bleed

valve.

3. Wait approximately 20 to 30 seconds.

4. As necessary, separate or connect the quick

disconnects.

5. Immediately close the bleed valve.

6. Restart the engine if necessary.

Outrigger Box Removal

NOTE: The outrigger box assembly weighs approximately

9427 lb (4276 kg).

1. Remove the counterweight. For more information, see

Counterweight Removal and Installation, page 5-12.

2. Program the RCL for the On Rubber, 360° Rotation, No

Counterweight (code 9810) load chart.

3. Remove the quick release pins (2, Figure 5-19) from the

ends of each of the pinning cylinder rod ends (3).

4. Using the crane boom for the lifting operation, fasten

lifting slings to the lifting lugs (4).

5. Lift the outrigger box enough to remove the pressure off

of the ends of the pinning cylinder rod ends (3).

DANGER!

Tipping Hazard

• Lifting the outrigger box must be done sitting on the

tires.

• While lifting the outrigger box on rubber, the Crane

must be positioned on a firm, level surface.

• When lifting the outrigger box while on rubber, the

boom must be limited to 8 m (25 ft) maximum radius.

• No counterweights are to be installed on the

superstructure if swinging over the side on rubber.

• With no load, do not exceed a 9 m (30 ft) load radius

over sides of machine since a loss of stability could

occur, causing a tipping condition. To lower boom into

a horizontal position, boom must be swung over the

front of the machine and the RCL bypass activated.

• After one outrigger box is installed, do not swing the

boom over that end of the machine while installing the

other outrigger box.

CAUTION!

Do not activate any switches on the control in Figure 5-18

or the remote control until you are thoroughly familiar with

the outrigger box installation and removal procedure.

Loading...

Loading...