2. CNC Monitor Screen

2.6 Data In/Out

I - 151

2.6.3.2 Machining Program Condense

The

storage efficiency of the machining programs registered in memory may be lowered when correction

such as data deletion or addition is made. When memory is used wastefully, the condense function can be

used to move the intermediate blank portions forward and increase the remaining number of characters

that can be registered.

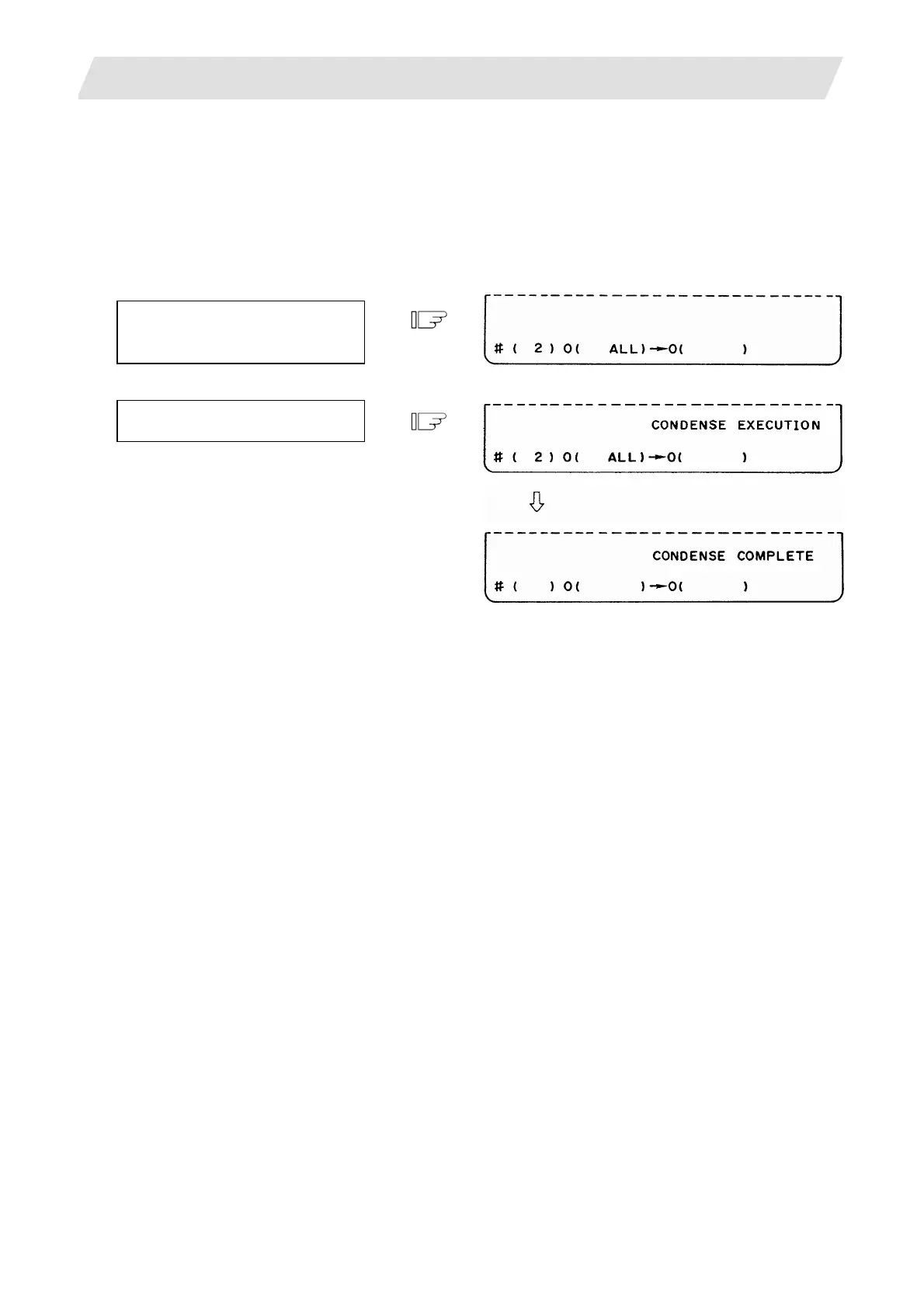

Set 2 in # ( ) for the condense command. To execute the condense function for all machining programs

registered in memory, set ALL in first 0 ( ).

To condense all work programs

registered in memory:

# (2) O (ALL) → O ( )

Press the [INPUT] key.

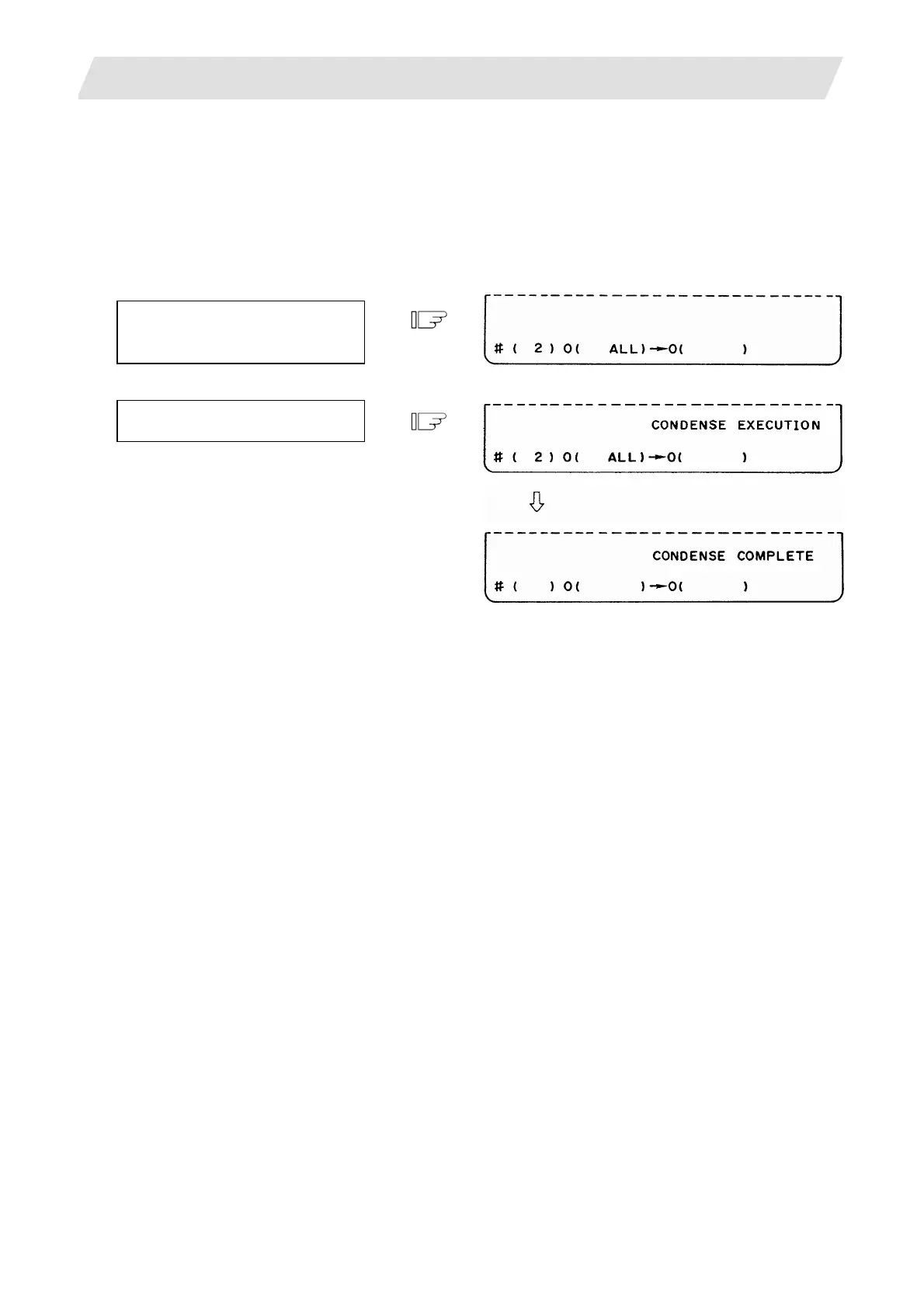

1) Condense is started and the message

CONDENSE EXECUTION is displayed in the

message field.

2) The time required for condense varies

depending on the total number of the registered

machining programs. Do not turn off the NC

power during condense execution.

Loading...

Loading...