2. CNC Monitor Screen

2.2 Monitor

I - 20

2.2.1.1 Position Display Counter Zero and Origin Zero

Coun

ter

Zero

The POSITION display only is set to zero and the absolute value data remains unchanged.

Origin Zero

This sets both POSITION display and absolute value data to zero.

It is equivalent to G92 X0 Y0 Z0 ;.

(Note) Origin zero is valid only when "#1123 origin" is set to 0.

In the following operations, the [INPUT] key

leads to the counter zero function and the [C.B

CAN] key leads to the origin zero (set zero)

function.

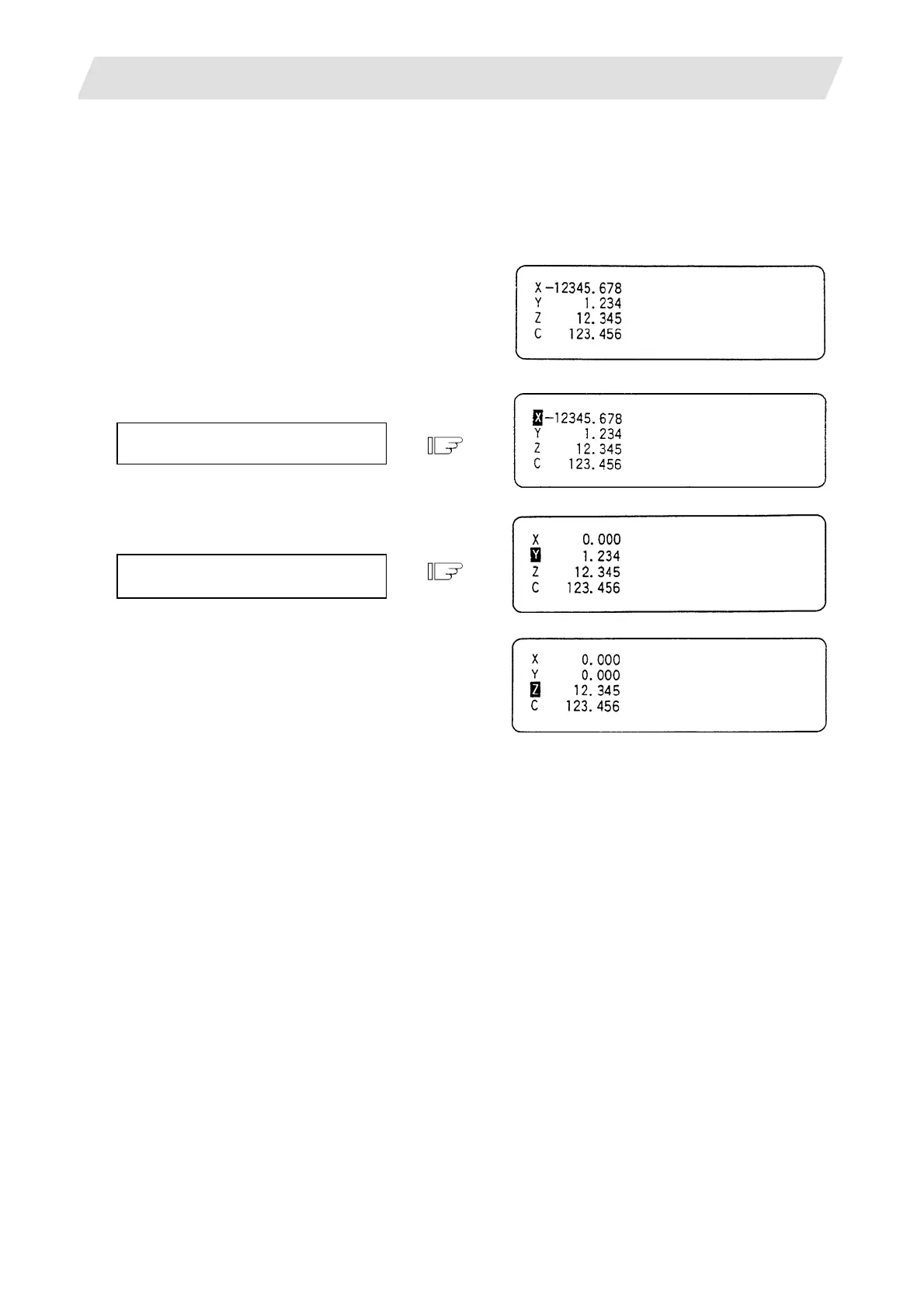

Press the address key [X]

.

1) The address indication corresponding to the

key is highlighted.

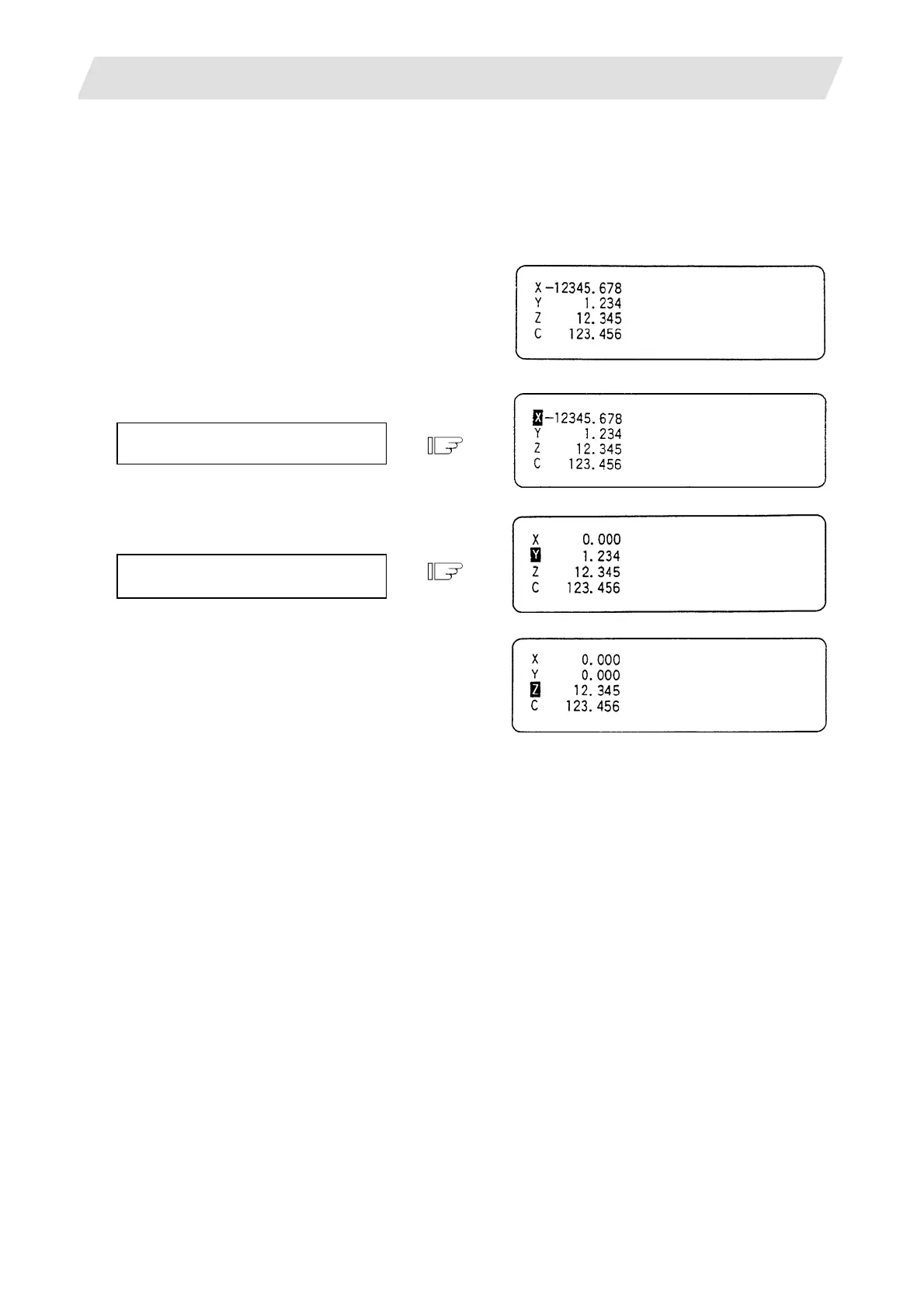

Press the [INPUT] key (counter zero)

or [C.B CAN] key (origin zero).

1) The axis position data is set to zero and the

next axis name is highlighted.

2) By repeatedly pressing the [INPUT] or [C.B

CAN] key, the position data of other axes

can be cleared to zero.

3) Upon completion of zero clear of final axis,

the display is no longer reversed.

4) If you press an axis address key midway,

the address of specified axis is highlighted.

5) When you press a key other than axis

address key, the display is no longer

reversed.

Loading...

Loading...