2. CNC Monitor Screen

2.7 Diagnosis

I - 197

2.7.9.2 Parameters

Paramete

rs for NC data sampling a

re set on this screen.

(Note 1) Parameter output is not executed for the data set on this screen.

(Note 2) "#0 SMP START" will return to "0" (sampling stop) at the power ON, while the data #1 to #37 will be

retained. However, When "#100 P.ON START" is set to "1", "#0 SMP START" will be set to "0"

when the power is turned ON and the sampling starts.

The parameters, which are rewritten from MS Configurator via API, will not be kept. The data

before adjustment/measurement will return when the power is turned ON again.

(Note 3) Setting the parameters #31 to #37 is basically not necessary. These parameters are for expanding

functions.

(Note 4) The parameters cannot be set when "#1224 aux08/bit0" is set to "0", "#1164 ATS" is set to "1" on

the base specifications parameter screen.

The error message "DATA PROTECTING" will occur when the setting is attempted.

(Note 5) The parameters except #0 cannot be set unless <STATE> shows "sampling stop".

The error "SETTING NOT POSSIBLE" will occur when the setting is attempted.

(Note 6) The parameters except #0 cannot be changed while a machining program is running.

The error message "PROGRAM RUNNING" will occur when the change is attempted.

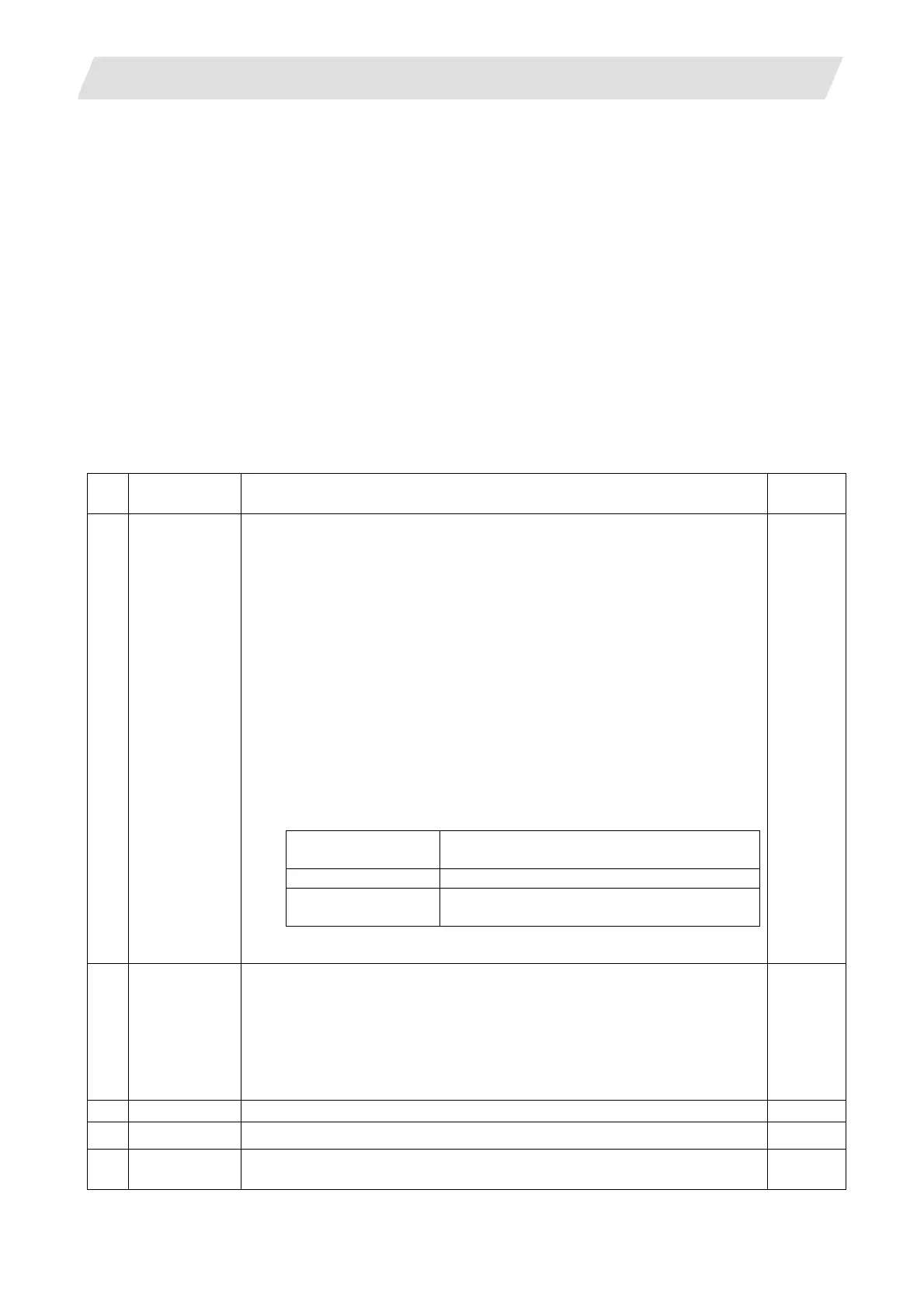

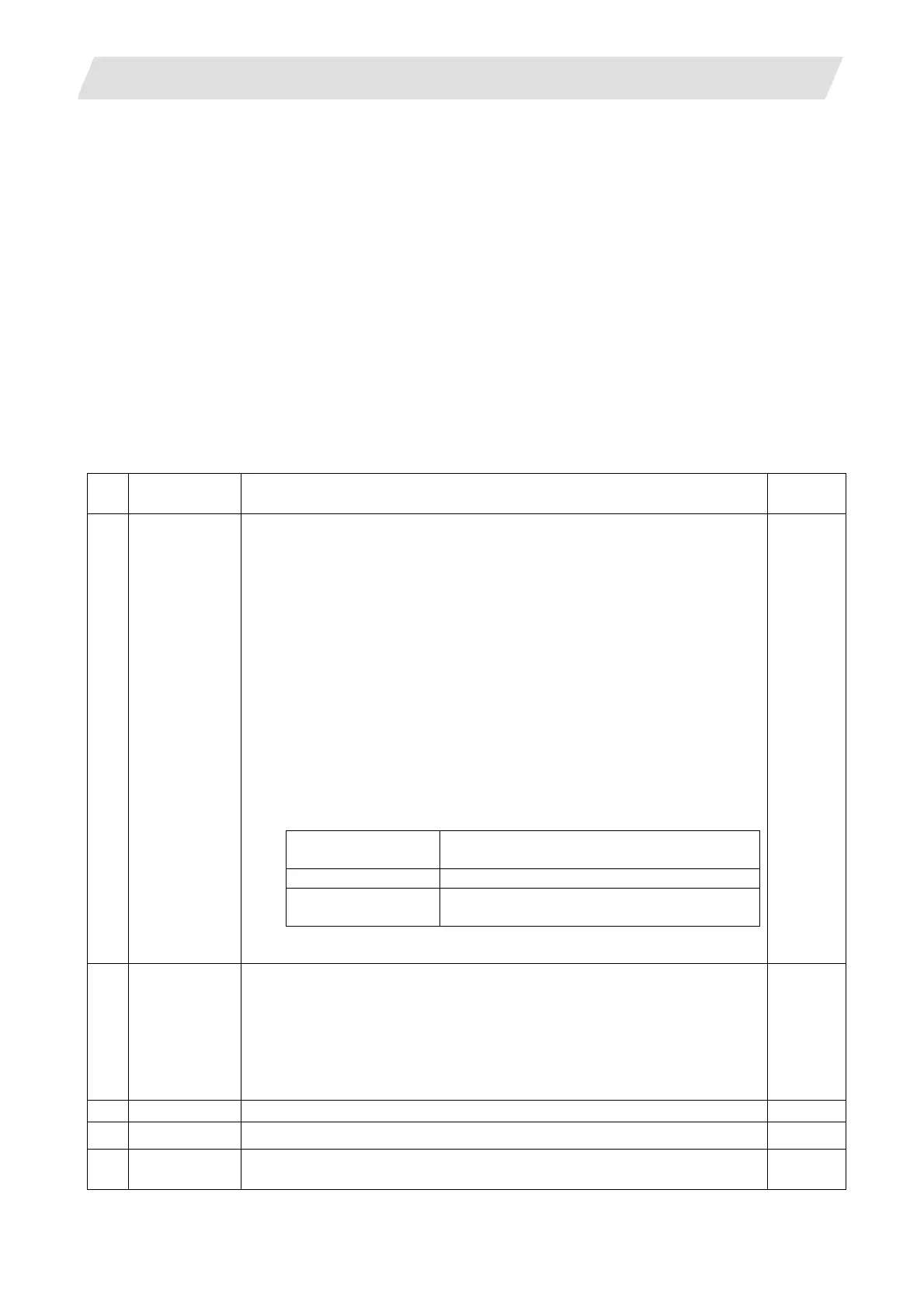

# Item Details

Setting

range

0 SMP START

Set "1" and then press "INPUT" to start sampling. The value will

automatically become "0" when the sampling is completed.

0: Sampling stop:

Sampling has not been executed or has been completed.

(This is usually not to be set by a user.)

1: Sampling start:

Sampling is being executed or in the "trigger wait" state.

9: Sampling forced end:

The sampling will stop immediately when this value is set during the

sampling process. Then the value will become "0".

(Note 1) If a user sets "0", the sampling will stop under the condition that

the "trigger wait" state or "ring buffer" type is selected.

Without the condition, the sampling state will not be changed.

(Note 2) The operation when "1" is set differs according to the "#5

S-CONDITION" setting.

"#5 S-CONDITION" Operation

when "1" is set for "#0 SMP START"

"0" (manual start) Sampling starts immediately.

Others

System waits for a trigger.

Sampling starts when the trigger is detected.

0,1,9

1 CYCLE

Set the sampling cycle.

Cycle = 0.8ms ∗ setting value

(Example) When set to "1": 0.8ms cycle, When set to "2": 1.7ms cycle

(Note 1) When there are many part systems and axes, the cycle is

"1.7ms * set value".

1 to 255

2 MARKS Set the number of channels for sampling. 1 to 8

3 BUFFER

Not used.

0

4 CAPACITY

Set the capacity (maximum number of data) of the buffer to use.

Maximum number of data = (Set value + 1)

∗

1024 points

0 to 1279

Loading...

Loading...