2. CNC Monitor Screen

2.3(I) Tool Offset (L system)

(Refer to "2.3 (II). Tool Offset (M system)" for Machining center system)

I - 51

2.3.2.3 Tool Presetter

(1) Outline

By using a device having a touch sensor, the tool compensation amount can be calculated just by

contacting the tool nose against the touch sensor with manual feed. The calculated results are stored

in the tool compensation amount memory.

After setting the tool compensation amount for each tool, the Z axis external workpiece coordinate

offset data can be set by cutting the edges of the workpiece with manual operation and inputting the

workpiece measurement signal.

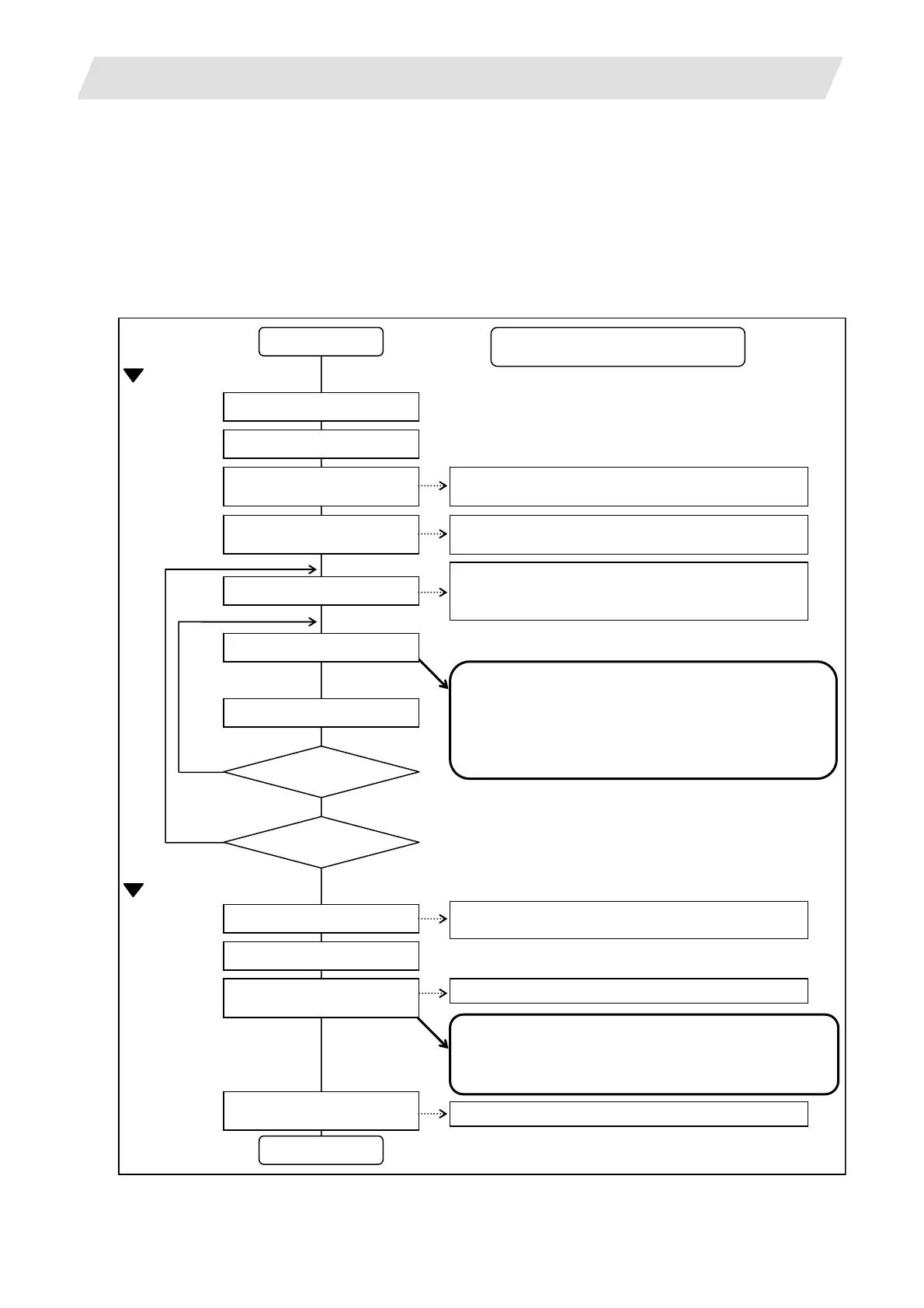

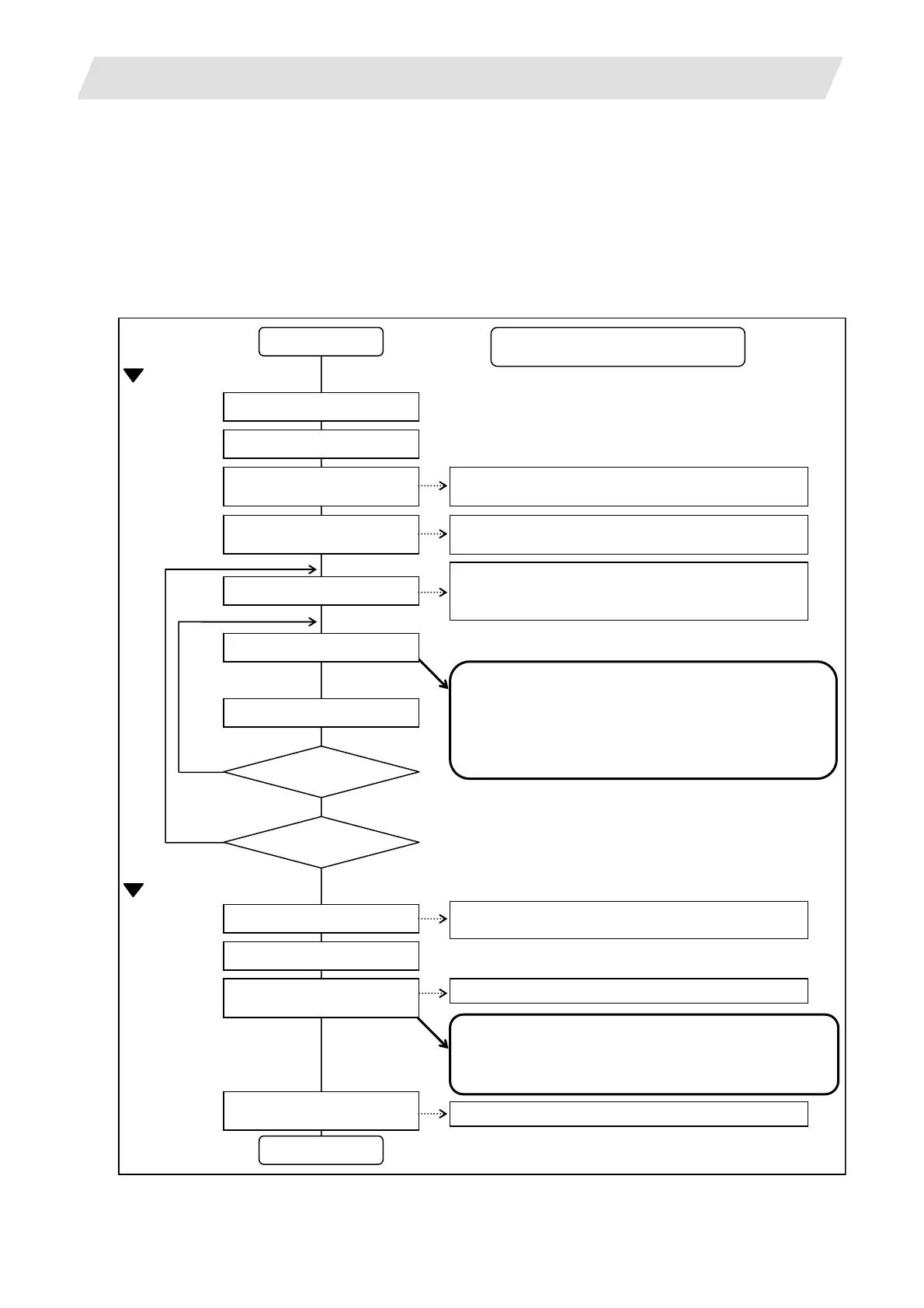

(2) Operation flow

Start of operation

Reference point return

Select manual mode

Turn tool measurement mode

TLMS

ON

Set measurement base

position

Set No. of tool to be measured

Contact tool against sensor

Select tool

Turn ON Y721 (tool measurement mode).

Preset the following axis specification parameter as the

sensor position. #2015 tlml–, #2016 tlml+

Set the compensation No. of the tool to be measured in

the R register.

Tool No.: R4720, Wear data compensation No.: R2431

♦ The axis movement will stop, and can be moved only

in the direction away from the sensor.

Set the compensation No. of the tool to be used for

cutting in the R register.

The tool length compensation amount is automatically

calculated from the contacted position, and is stored in the

tool compensation amount memory.

Tool compensation amount = Machine coordinate value

– Measurement base position (Sensor position)

The wear amount is cleared after measurement.

Retract tool

Cut workpiece edges

Measure other axes?

Measure other tools?

♦ The tool compensation amount is measured one axis at a time.

♦ Do not move the tool in the Z axis direction after cutting.

Turn tool measurement mode

[TLMS] OFF

End of operation

The Z axis workpiece coordinate offset will be measured

and set in the external workpiece offset.

Workpiece coordinate offset = Machine coordinate value

– Tool compensation data

Turn ON Y7B1 (workpiece measurement No.) Input workpiece measurement

signal

Turn OFF Y721 (tool measurement No.)

Interface and operation with NC

No

No

Yes

Yes

External workpiece offset

Tool compensation amount

Loading...

Loading...