2. CNC Monitor Screen

2.3(I) Tool Offset (L system)

(Refer to "2.3 (II). Tool Offset (M system)" for Machining center system)

I - 64

2.3.5.2 Tool Life Incrementation Methods

The tool life can be incre

mented either by time method or by the No. of uses (count) method.

If the USED data equals or exceeds the LIFE data as a result of incrementation, a spare tool will be

selected from that tool's group by the next relevant group selection command (T****99). After that, the

incrementation will be for the newly selected tool (the spare tool selected). If the life of all tools in a group is

reached, and a spare tool cannot be selected, the incrementation will continue for the last tool selected.

(1) Time incrementation with the time method

The time the tool is used in the cutting mode (G01, G02, G03, G31, G33, etc.) is incremented in 100ms

units.

The time is not incremented during dwell, machine lock, miscellaneous function lock, dry run or single

block status.

(Note) • The max. life value is 999999 min.

• The data on the TOOL LIFE screen is displayed in minute units.

(2) No. of uses (count) incrementation with the count method

Incrementation is carried out when the No. of the tool being used changes by the execution of a tool

selection command (T****99) during the cutting mode (except during machine lock, miscellaneous

function lock, dry run, and single block states). (If the mode never changes to the cutting mode after the

tool No. changes, the count is not incremented.)

(Note) • The max. life value is 999999 times.

• If only the compensation No. for the current tool changes, the count is not incremented.

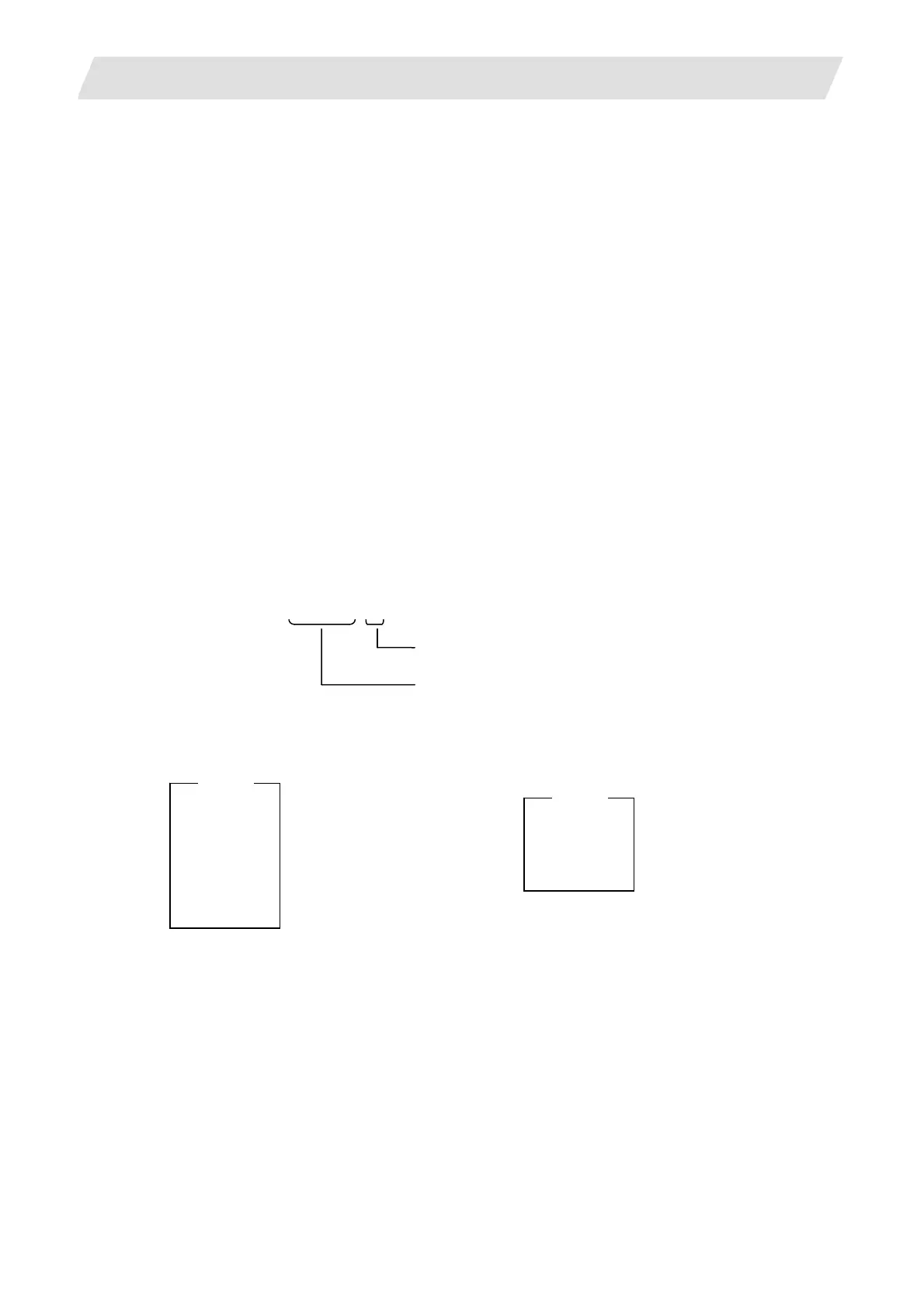

If the T code of the current tool is 12345678:

T 1 2 3 4 5 6 7 8

Compensation No.: The count is not incremented,

even if this changes.

Tool No.: The count is incremented when this

changes.

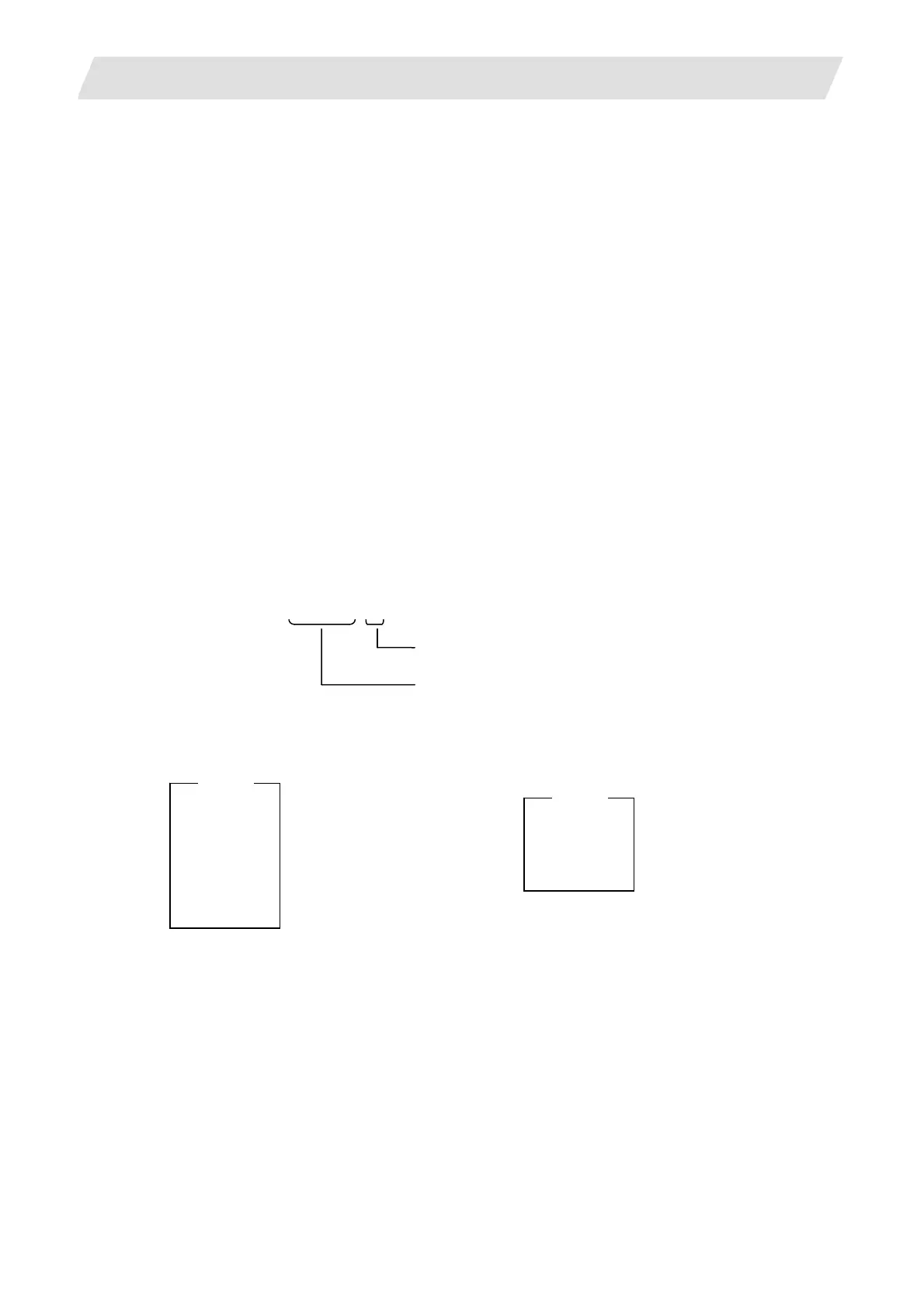

<< Operation example >>

T0199 (1)

:

T0299

:

T0199 (2)

:

T0299

:

T0199 (3)

Program

T0199 (1)

:

T0199

:

T0199

Program

The count for group 01 is 1 time.

The count for group 01 is 3 times.

(Note) The count is for one program execution.

If the program is executed again after resetting the count will be incremented.

Loading...

Loading...