Appendix 5. Table of Conversion Codes for Error Code Output

Appendix 5.1 Code Conversion Specifications

IV - 19

Appendix 5. Table of Conversion Codes for Error Code Output

With this function, the CNC alarms and errors which are normally output to CNC screen are partially

coded and output to PLC I/F device. Thus, the contents of alarms and errors can be confirmed without

CNC screen.

Appendix 5.1 Code Conversion Specifications

The following output will be made when an alarm occurs.

The message displayed in CNC screen is not converted.

(Example) When servo alarm S03 occurs

S03 SERVO WARNING 0052 XZ

xis name

larm No.

larm message

larm type

The output is as shown above on the CNC screen. However, this can be coded and output to PLC I/F

device as shown below using this function.

Alarm type

··················

Converted into a 2-digit numeral code. (Refer to the section 5.2.)

Alarm message

··········

Not coded, and not output.

Alarm No.

···················

The No. is output as HEX.

Axis name

··················

Error occurrence axis is expressed as a bit, and the bit of servo and

spindle are output separately. The head digit of the alarm without axis

name will be “0”.

The output to PLC I/F device is as follows.

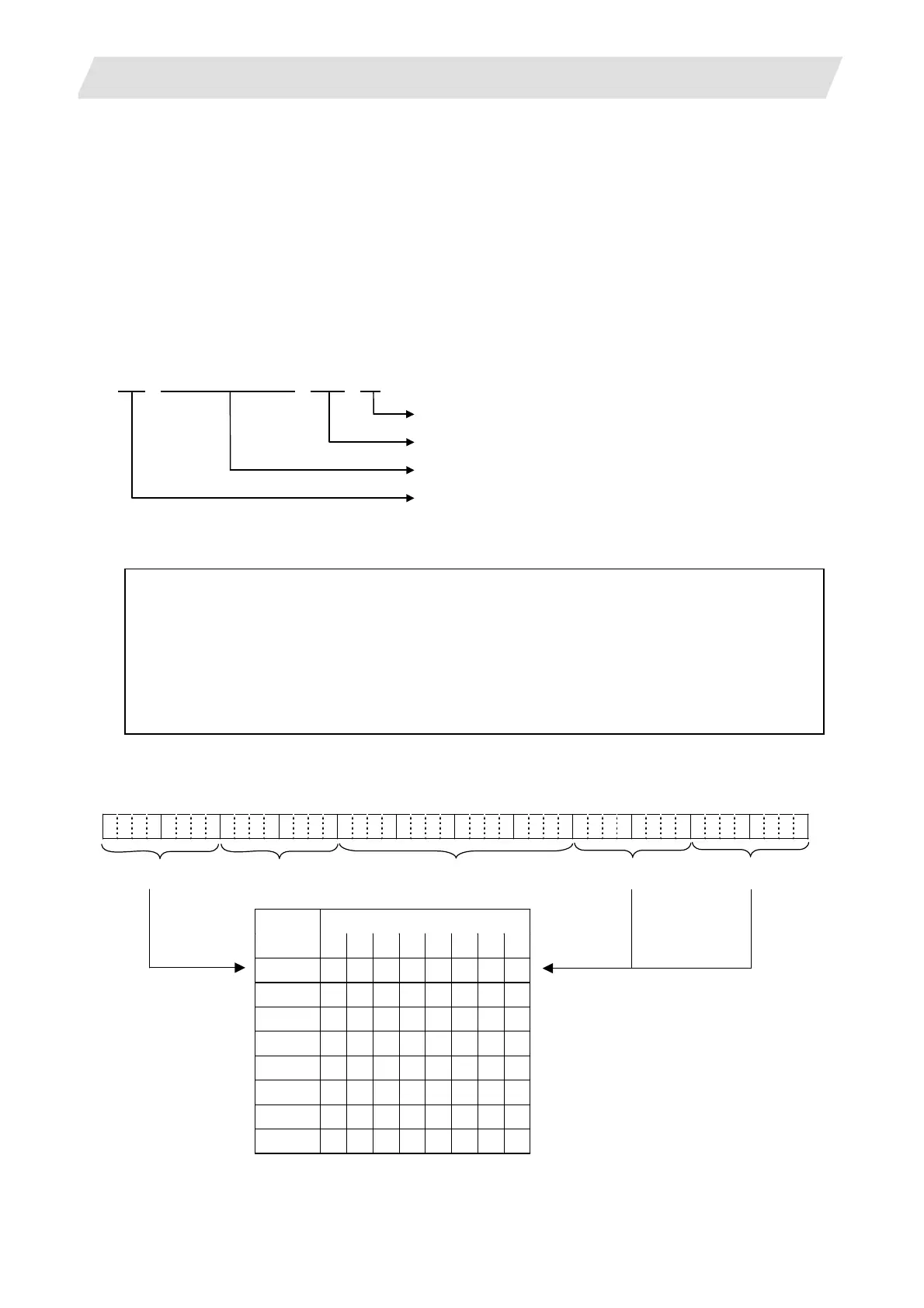

0 0 0 0 0 0 0 0 0 0 1 10 0 1 1 0 0 0 0000001010010000001 0 1 0 0 0 0 0 000

bit

7 6 5 4 3 2 1 0

1st axis 0 0 0 0 0 0 0 1

2nd axis 0 0 0 0 0 0 1 0

3rd axis 0 0 0 0 0 1 0 0

4th axis 0 0 0 0 1 0 0 0

5th axis 0 0 0 1 0 0 0 0

6th axis 0 0 1 0 0 0 0 0

7th axis 0 1 0 0 0 0 0 0

8th axis 1 0 0 0 0 0 0 0

larm t

pe

Servo axis name

larm No.

Spindle name

PLC axis name

s for the servo axis name and spindle

name, the bit corresponding to the No. of

axis in which the alarm occurs is turned

on.

The max servo axis Nos. in the 1st part

system are 16, and the max spindle Nos.

in the 1st part system are 7. The spindle

alarm is output to the 1st part system.

The PLC axis name is output to the 1st

part system.

G10358/R158

(Higher side)

G10358/R158

(Lower side)

G10357/R157

(Higher side)

G10357/R157

(Lower side)

G10356/R156

(Higher side)

G10356/R156

(Lower side)

Axis name is added for the messages such as some of M01, S01 to S52, and Z70 to Z73.

The following 48 bits are used as the output PLC I/F devices.

Loading...

Loading...