III - 17

4. Periodic Inspection

4. Periodic Inspection

The items that must be inspected one or two times every 6 months to 1 year are listed below.

When the equipment is moved or modified, or layout of the wiring is changed, also implement this inspection.

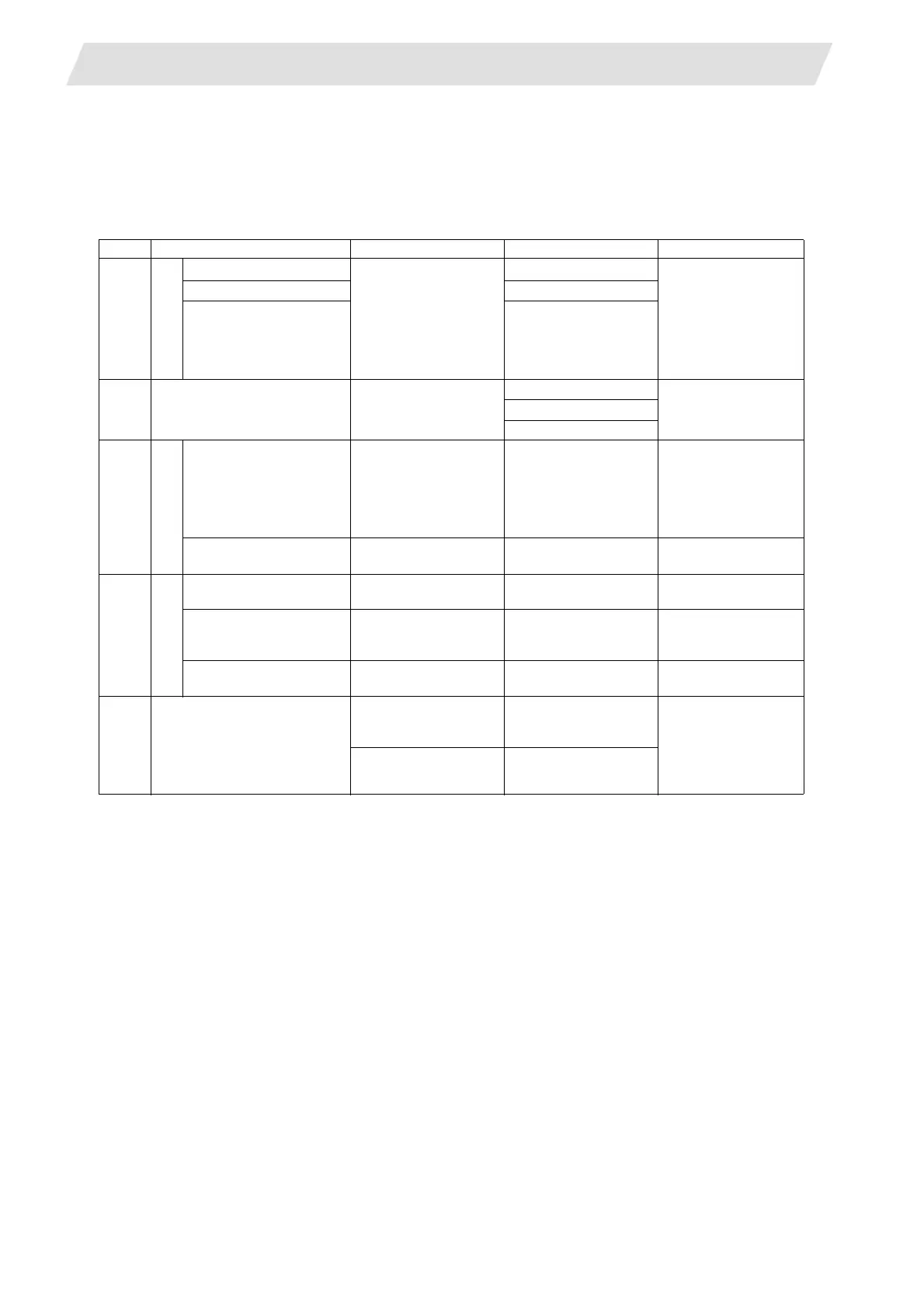

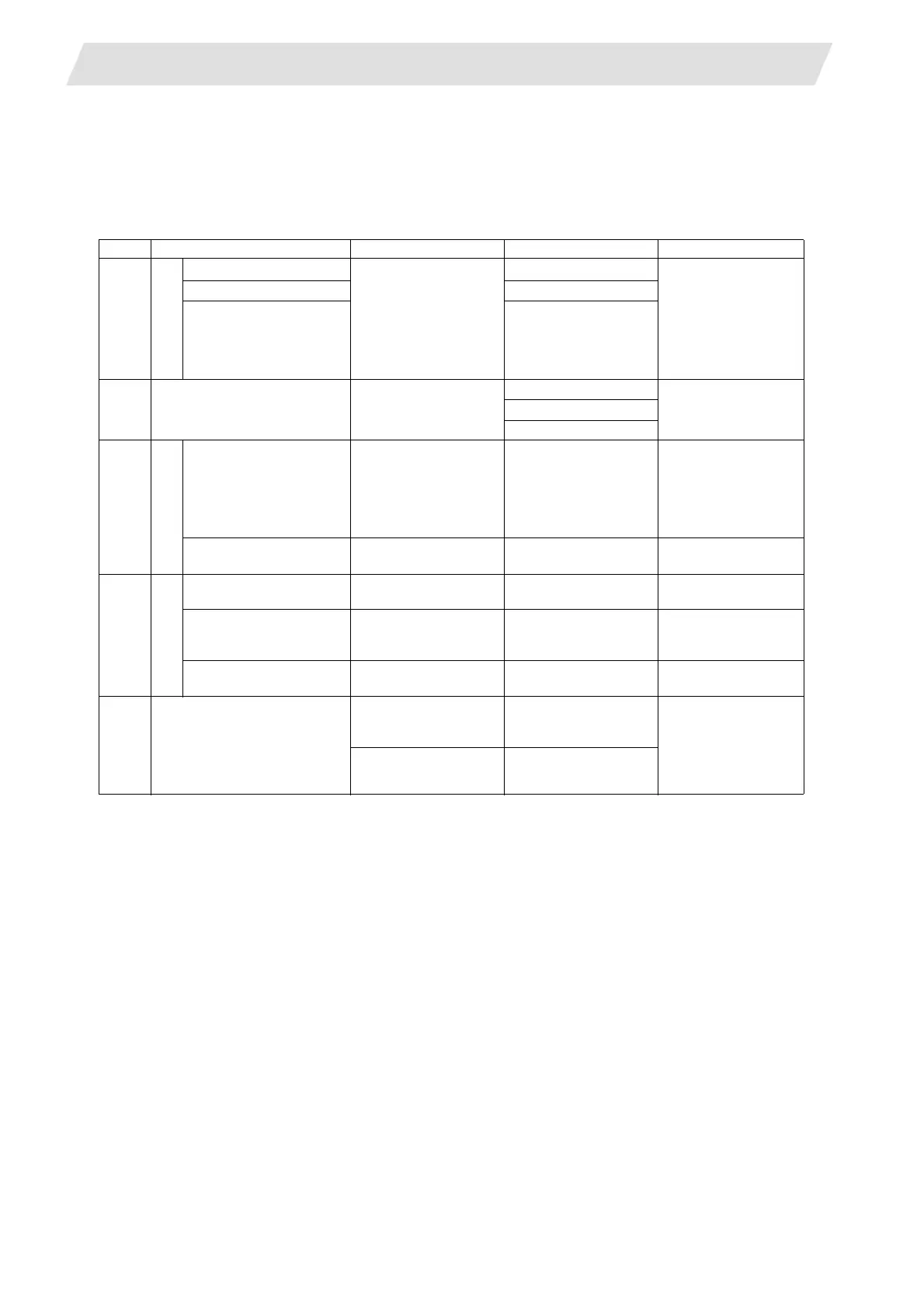

Item Inspection item Inspection Criterion Action

1

Ambient environment

Ambient temperature

Measure with a

thermometer and a

hygrometer.

Measure corrosive gas.

0 to 55 °C (32 to 131 °F)

When the controller is

used in the board, the

ambient temperature in

the board becomes the

ambient temperature

Ambient humidity 5 to 95 % RH

Atmosphere No corrosive gases

2 Power voltage

Measure a voltage across

the terminals of 100/

200VAC and 24VDC.

85 to 132VAC

Change the power supply.170 to 264VAC

15.6 to 31.2VDC

3

Installation

Looseness, rattling

Move the module to check

for looseness and rattling.

The module must be

installed solidly.

Retighten the screws.

If the CPU modules,

Motion modules, I/O

modules, or power supply

modules are loose, fix it

with screws.

Adhesion of dirt and foreign

matter

Check visually.

Dirt and foreign matter

must not be present.

Remove and clean.

4

Connection

Looseness of terminal screws

Try to further tighten

screws with a screwdriver.

Screws must not be loose.

Retighten the terminal

screws.

Proximity of solderless

terminals to each other

Check visually.

Solderless terminals must

be 4 positioned at proper

intervals.

Correct.

Looseness of connectors Check visually.

Connectors must not be

loose.

Retighten the connector

fixing screws.

5 Battery

Check the 7-segment LED

at the front side of CPU

module.

Must be turned OFF "BT1"

or "BT2" display.

Even if the lowering of a

battery capacity is not

shown, replace the

battery with a new one if a

service life time of the

battery is exceeded.

Check the length of term

after purchasing the battery

Must not be used more than

5 years.

Loading...

Loading...