2. CNC Monitor Screen

2.6 Data In/Out

I - 152

2.6.3.3 Machining Program Merge

T

o prepare a new machining program by using the machining program contents stored in memory, one

machining program can be followed by a copy of another program. The two programs are merged into a

new program.

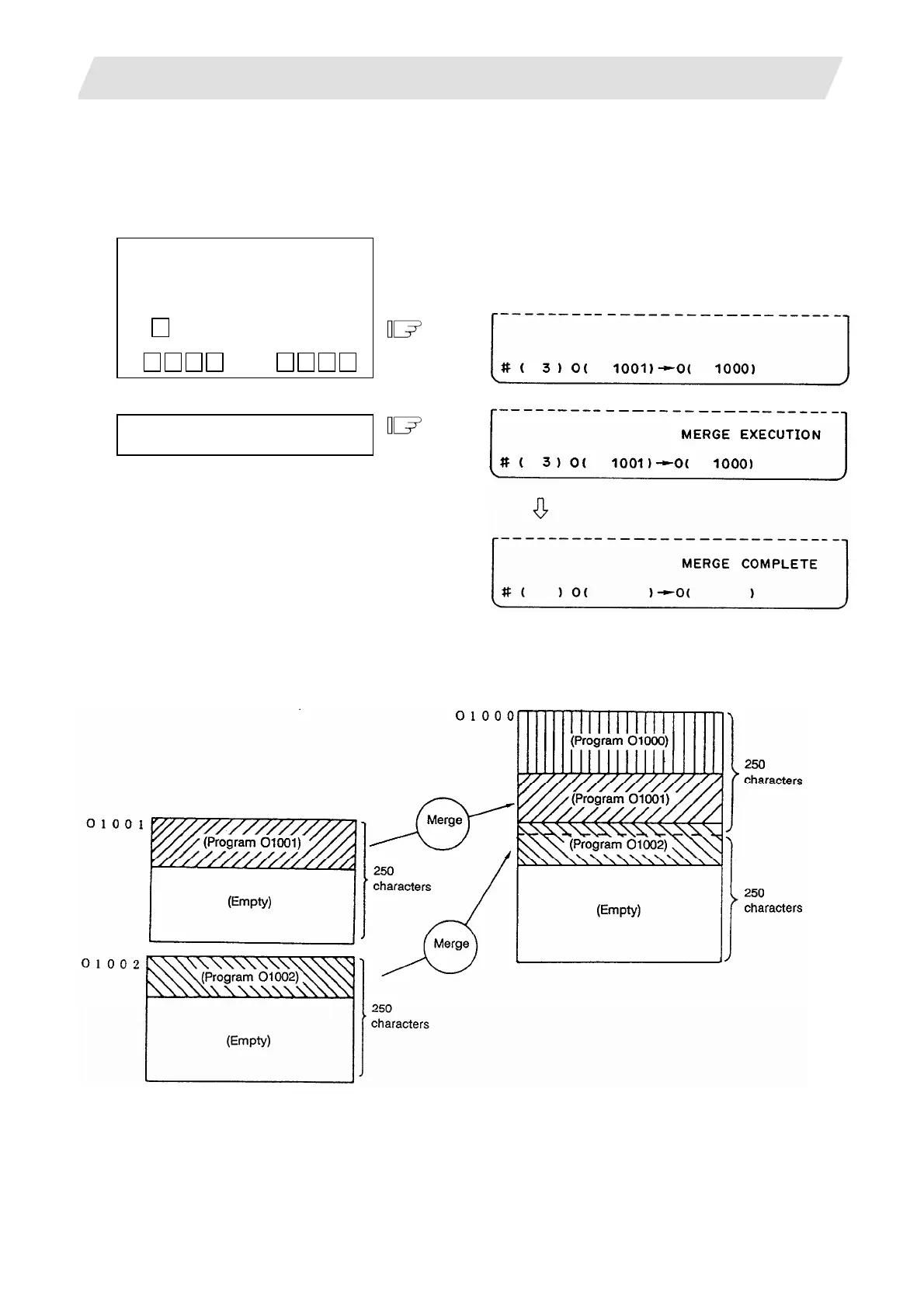

Set 3 in # ( ) for the merge command. Set the copy source and destination program numbers in order.

(Example 1)

To move program O1001 to the

area following program O1000 for

merge

# ( 3

)

O ( 1

0 0 1 ) → O ( 1 0 0 0 )

Press the [INPUT] key.

1) Merge is executed and the message MERGE

EXECUTION is displayed in the message field.

It may be terminated in a moment (when there

is less transfer data).

2) When the merge is completed, the message

MERGE COMPLETE is displayed in the

message field.

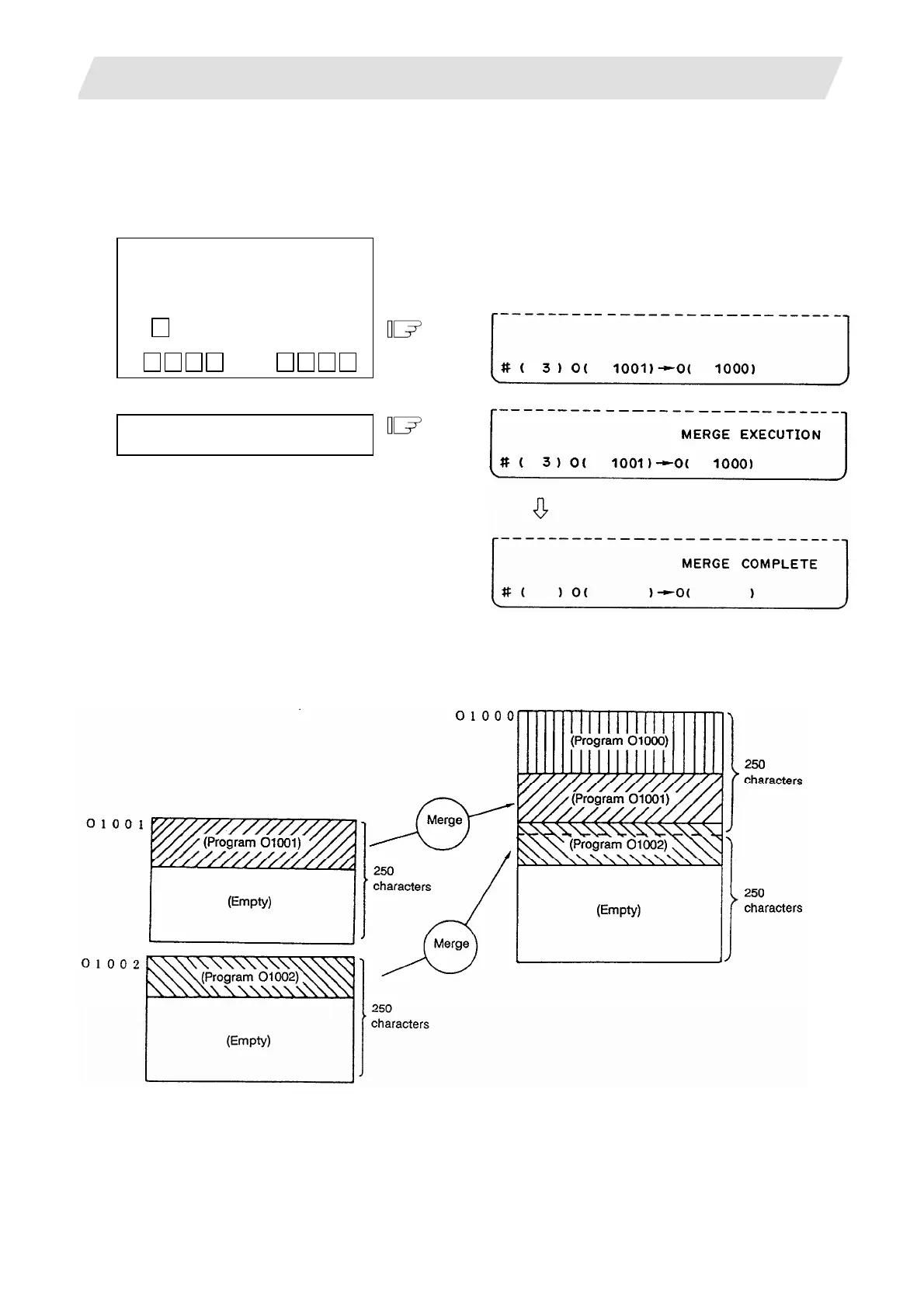

(Example 2) When program O1002 is moved to the area following program O1000 for merge after

operation in Example 1 (previous page), a new program is prepared as shown below. The

three programs are merged into O1000. O1001 and O1002 remain unchanged.

Loading...

Loading...