2. CNC Monitor Screen

2.1 Setting and Display Unit Operation

I - 9

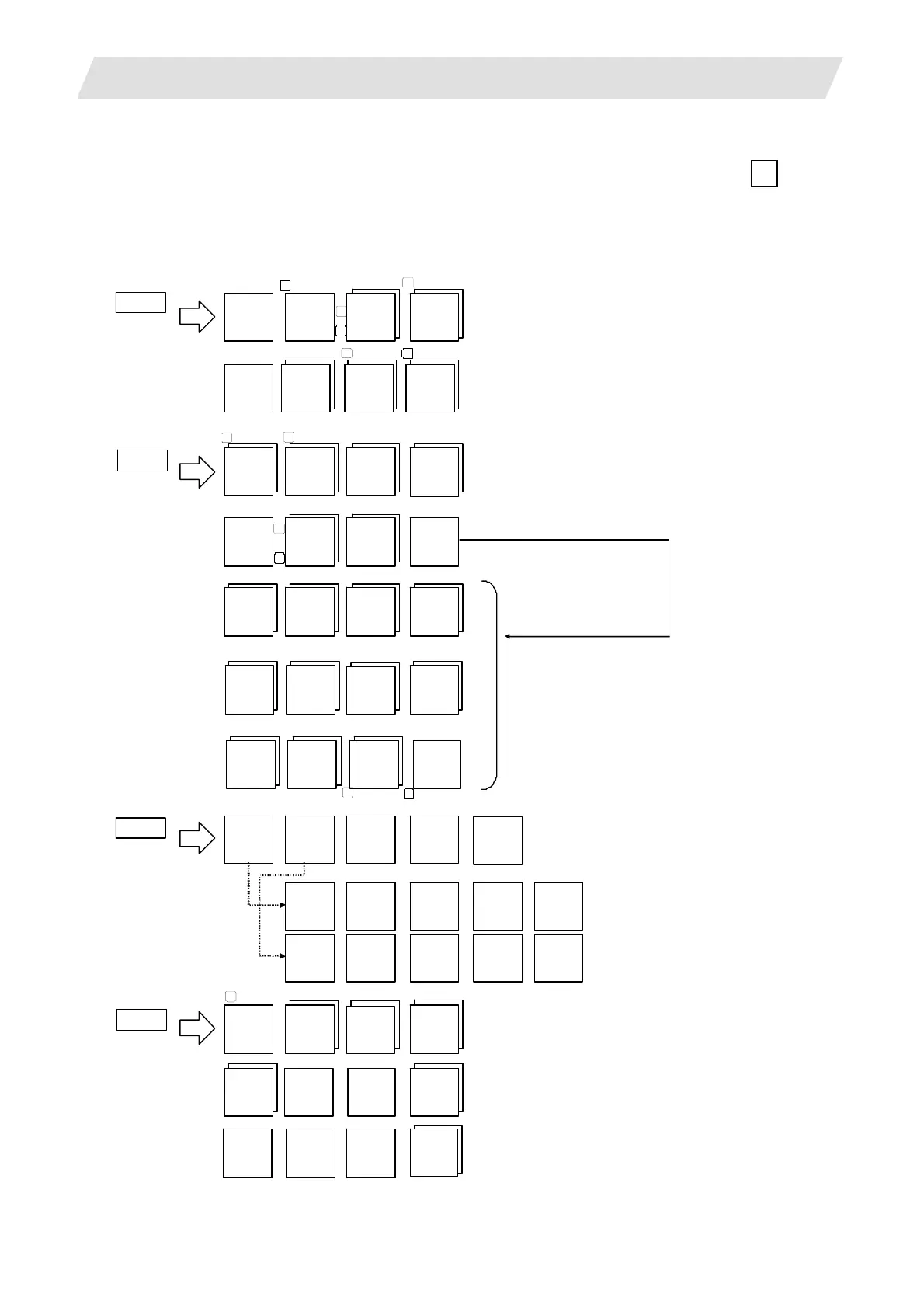

2.1.3 Screen Transition Diagram (M system)

If the multi-part system is provided, the displayed part system for screens indicated with the

$

mark will

change when the [SHIFT] and [4] keys are pressed.

All data may not fit on one page according to the number of part systems or number of axes.

Use the [BACK] and [NEXT] keys to change the page in this case.

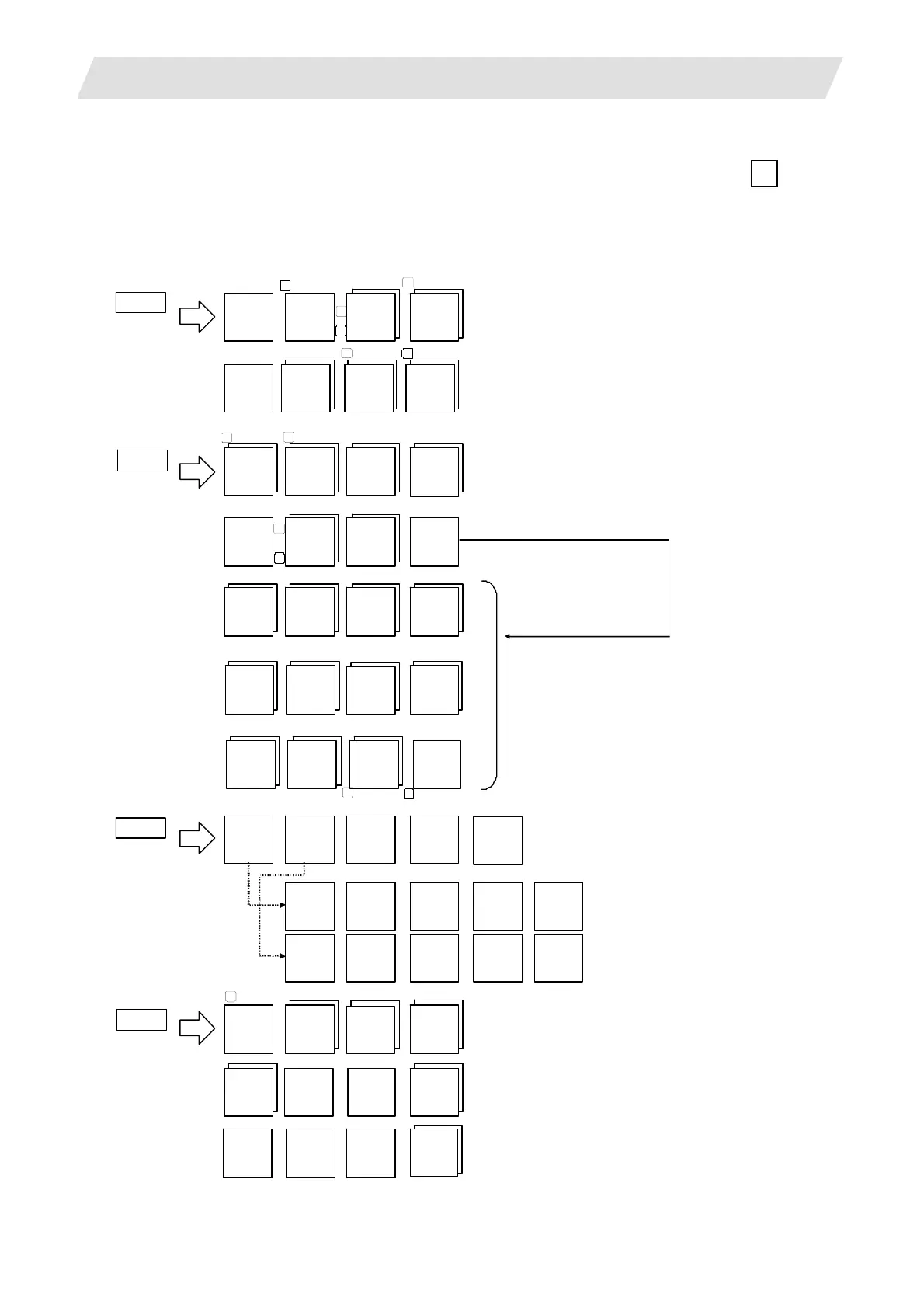

TOOL

LIFE

TOOL

OFFSET

T-

REGIST-

RATION

OPEN

SETUP

PARA M

WORK

OFFSET

PROCESS

CONTR OL

AXIS

BARRIER

SERVO

PA RA M

MULTI

CPU

PA R AM

BASE

SPEC

PARAM

AXIS

SPEC

PARAM

#1000 # 2000 #2200 #26700

The setting can be displayed

when [OPEN SETUP PARAM] is selected.

#8000

COMMON

VARIABLE

LOCAL

VARIABLE

$ $

$

$

$

$

POSITION COO RDINATE

COMMAND

MODAL

INFORM.

TIME

PROGRAM

SEARCH

[MENU1] [MENU2] [MENU3] [MENU4]

$

$

$

$

MONITOR

TOOL

PARA M

SP IN DL E

BASE

SPEC.

PARAM

#3000

SPINDLE

SPEC.

#13000

MACRO

FI LE

PO S ITI O N

SW IT CH

MC-ERR.

CMP.

PLC

TIMER

#4000,#5000 #6000 #7000, #27000 #7000

$

$

MDI

MDI

EDIT

MDI-ENT

PROGRAM

SMA LL

LARGE

FIL E

SE ARC H

SPINDLE

MONITOR

SPINDLE

DIAGNOSIS

PLC-I/F

ALARM

MESSAGE

SERVO MONITO R

SERVO DIAGNOSIS

PS DIAGNOSIS

SYN CHRONO US

ABS SER VO

MONITOR

ABS POSITION

SET

PLC AXIS

MONITOR

OPERATION

HISTORY

S/W MODULE

TREE

H/W MONITOR

OP T I ON

EDIT

$

EDIT MDI

DIAGN

IN/OUT

PROGRAM

ERASE

PROGRAM

FILE

PROGRAM

COPY

INDEX

PARAM

NC-DATA

SAMPLING

#12800

#29000

Net

PARAM

Loading...

Loading...