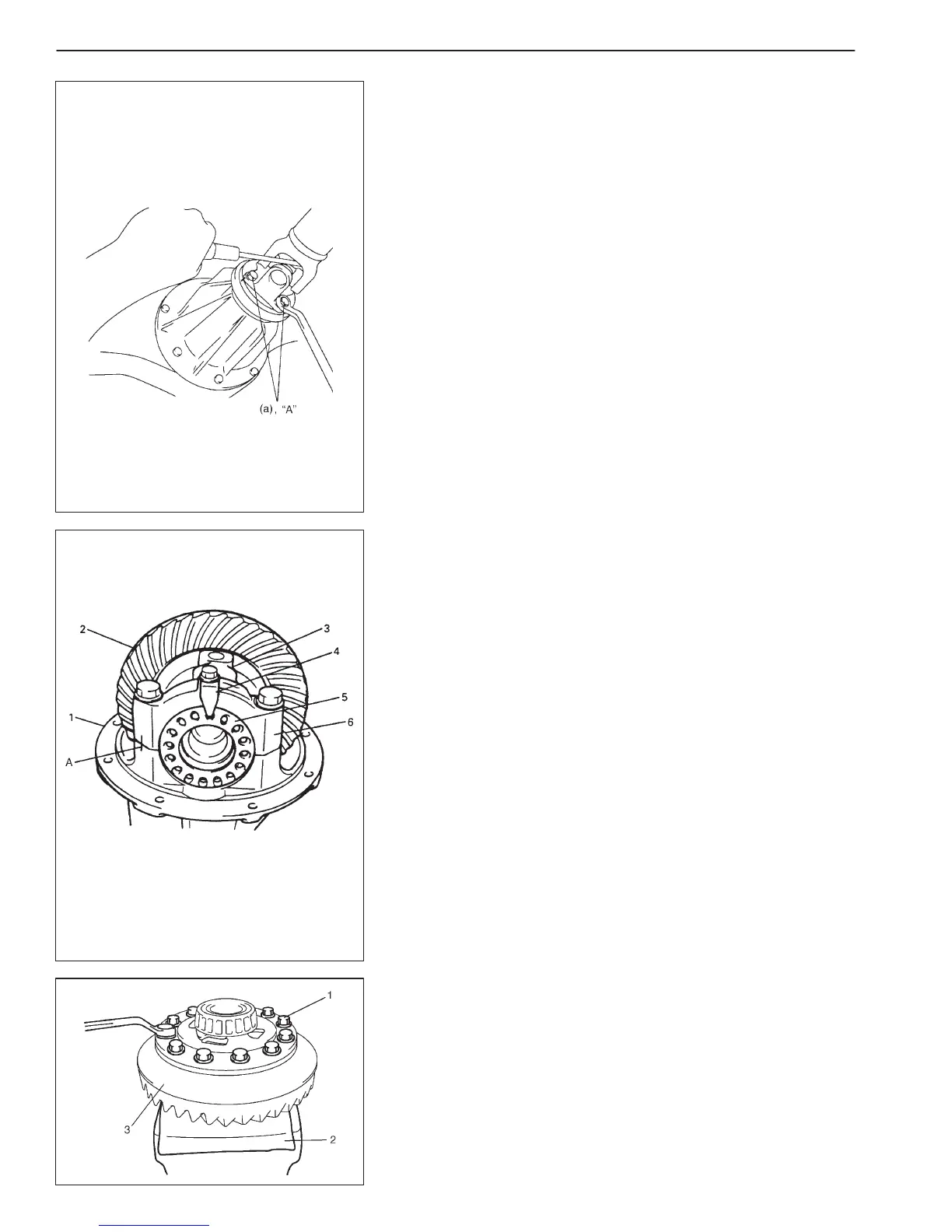

1. Differential carrier

2. Drive bevel gear assembly

3. Differential case

A: Identification mark

7F-6 DIFFERENTIAL (REAR)

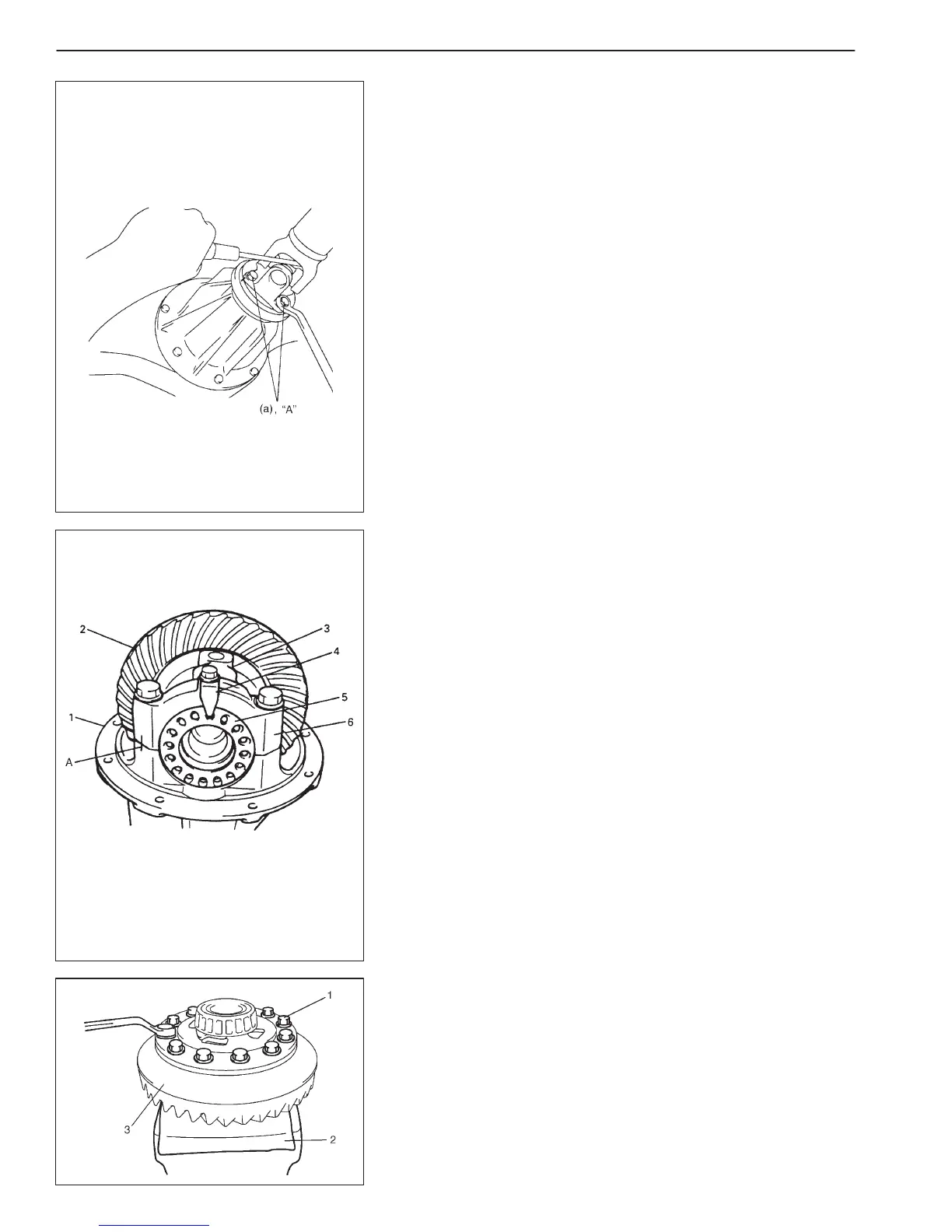

3) Install propeller shaft to joint flange aligning match marks and

torque flange bolts to specification. Apply thread lock cement to

thread part of bolt if reused.

“A”: Cement 99000-32110

Tightening torque

Propeller shaft flange bolts (a):

60 N

.

m (6.0 kg-m, 43.5 lb-ft)

4) Install right and left rear axle shafts and drums.

(Refer to “REAR AXLE INSTALLATION” of Section 3E and rear

brake drum installation of Section 5.)

5) Install wheels.

6) Fill hypoid gear oil as specified and tighten plug to specification.

7) Lower lift.

UNIT REPAIR

DISASSEMBLING UNIT

1) Hold differential assembly securely and put identification marks

on differential side bearing caps (6).

2) Take off differential side bearing lock plates (4) and differential

side bearing caps (6) by removing their bolts and then take out

bearing adjusters (5), side bearing outer races and drive bevel

gear with differential case.

3) Remove drive bevel gear (hypoid gear), differential gears, differ-

ential pinions and pinion shafts.

a) With aluminum plates (2) placed on vise first, grip differential

case with it and remove drive bevel gear (hypoid gear) (3) by

removing its bolts (1).

Loading...

Loading...