DAILY CALIBRATION

W

ALK-AROUND CHECKS OF INTELLIGENT MACHINE CONTROL EQUIP-

MENT

Check once a day before starting the engine that the bolts and nuts of the intelligent Machine Control are not

loose, the wiring harness connector is not loose, and the play is proper.

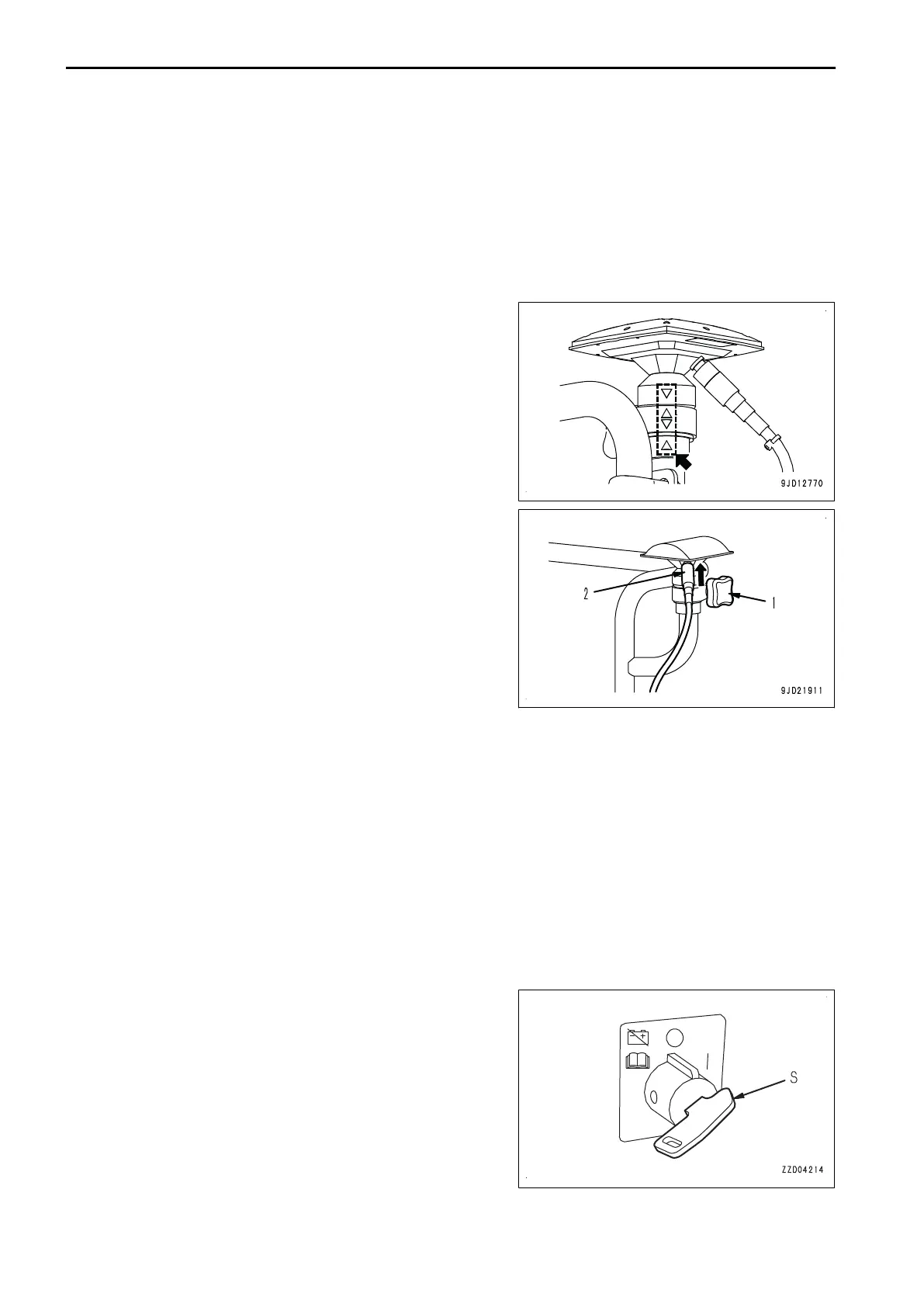

METHOD FOR CHECKING GNSS ANTENNA AND CABLE

1.

Check that the installing direction of GNSS antenna

matches marks.

If

it is misaligned, loosen the mounting knob (1) and align it

so that marks are in a straight line.

2.

When the connector (2) of GNSS antenna is connected,

tighten the thread while pushing it in the direction of arrow.

If it is tightened lightly, it may become loose during opera-

tion.

METHOD FOR CHECKING GNSS RADIO DEVICE

When GNSS radio device is installed, check that antenna is not faulty, installed position is not behind the ma-

chine, antenna cable coating is not damaged, and connector is not loosened.

METHOD FOR CHECKING LOOSENESS OF CONTROL BOX

1.

Check that the control box is located in the position for you to see it well, and the visibility of front right of

cab is good. If visibility is not good, adjust the angle of control box.

2.

Check that control box is fixed securely. If mounting knob is loose, retighten it further.

METHOD FOR CHECKS BEFORE STARTING ON intelligent Machine Control

EQUIPMENT

Before starting the work each day, perform the following inspection to check that the intelligent Machine Control

is detecting the bucket edge position correctly.

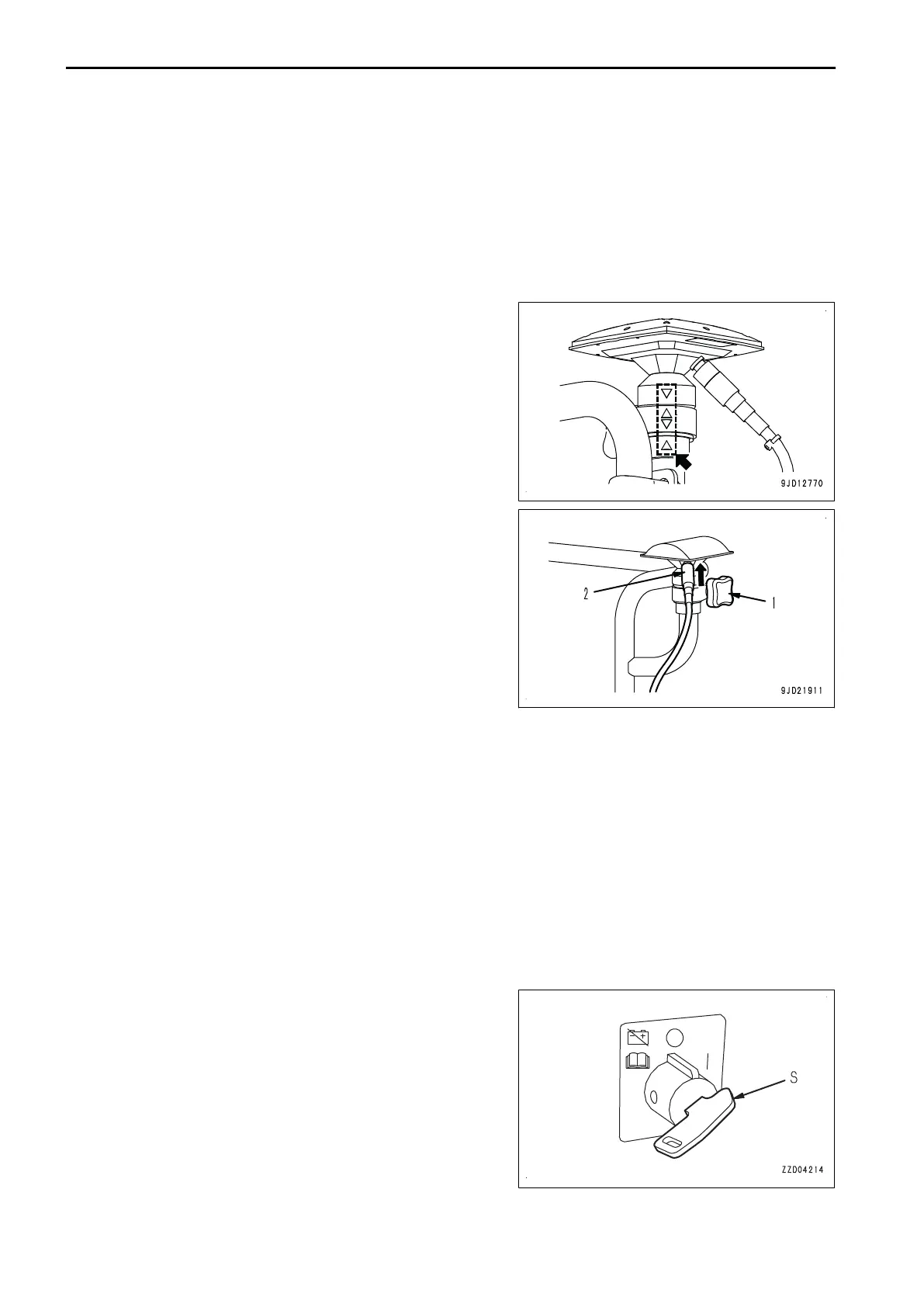

1.

Check that the battery disconnect switch (S) is in ON posi-

tion (I).

DAILY CALIBRATION EXECUTIONS

8-30

Loading...

Loading...