5

"Parameters" Operating Area 03.04

5.2 Tool offsets

5

Ó Siemens AG, 2004. All rights reserved

5-182 SINUMERIK 840D/840Di/810D Operator's Guide HMI Advanced (BAD) – 03.04 Edition

Offsets that are not required must be assigned the value 0 (= default

when the offset memory is set up).

The tool offsets can be entered not only via the operator panel front

but also via the data input interface.

For programming offset data see

/PG/, Programming Guide, Fundamentals

5.2 Tool offsets

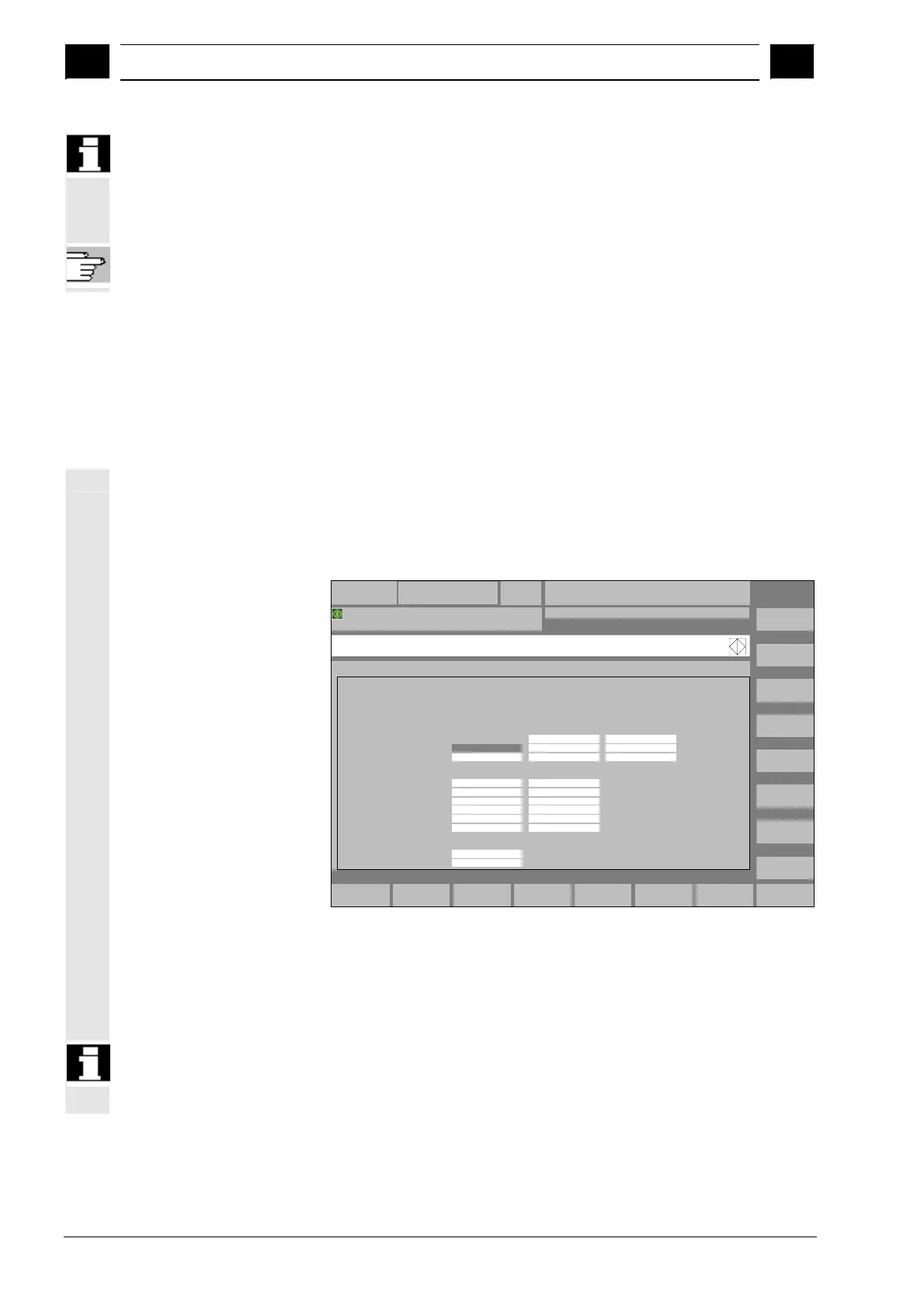

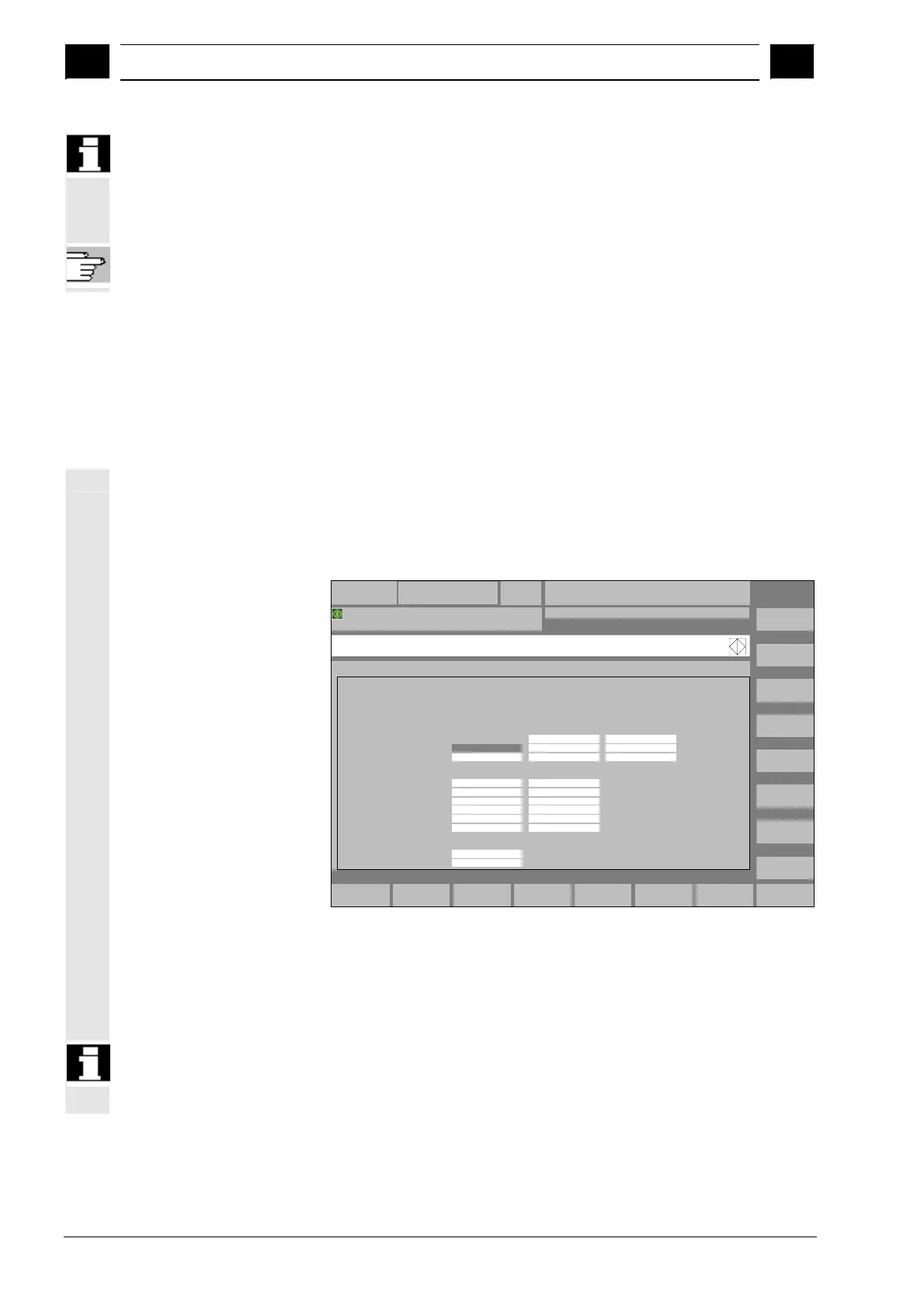

5.2.1 Function and main screen for tool offsets

Tool offset data consist of data which describe the geometry, wear,

identification, tool type and the assignment to parameter numbers.

The unit used for the dimensions of the tool are displayed.

The input field is highlighted.

T No.

Go to...

Overview...

New...

Determine

compens...

Delete...

Tool

offset

R

variables

Setting

data

User

data

Zero

offset

MPF.DIR

TEST.MPF

Channel active

AUTO CHAN1Parameter

T No.

-

D No.

+

D No.

-

:

:

:

:

:

:

T number 1

Tool type 100

C. edge pos. 1

D number 1 No. of c. edges 1

Geometry Wear

Deg.

Base

Tool length comp.

Radius comp.

Length compensation

Length 1 :

mm

Length 2 :

Clear angle

DP25.res :

mm

Length 3 :

mm

Radius : mm

DP7.18.res

DPR.17.res

DP9.18.res

DP10,19.res

DP11,20.res

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

Tool offset data

+

Program running

Every offset number contains up to 25 parameters depending on the

tool type.

The number of parameters shown in the window is that for the tool

type.

The maximum number of offset parameters (T and D numbers) can

be set by means of machine data.

Loading...

Loading...