T200 User's Manual SECTION 6: T200 FUNCTIONAL OVERVIEW

PAGE 6-74

6.13.2.4 MONITORING T200 PARAMETERS

Message Transmission to T200

The command code for monitoring a parameter is 01. The data required is:

• Parameter number (least significant byte followed by most)

• Size of parameter to read (2 or 4 bytes).

To monitor a parameter, the following message (series of bytes) should be sent to the T200:

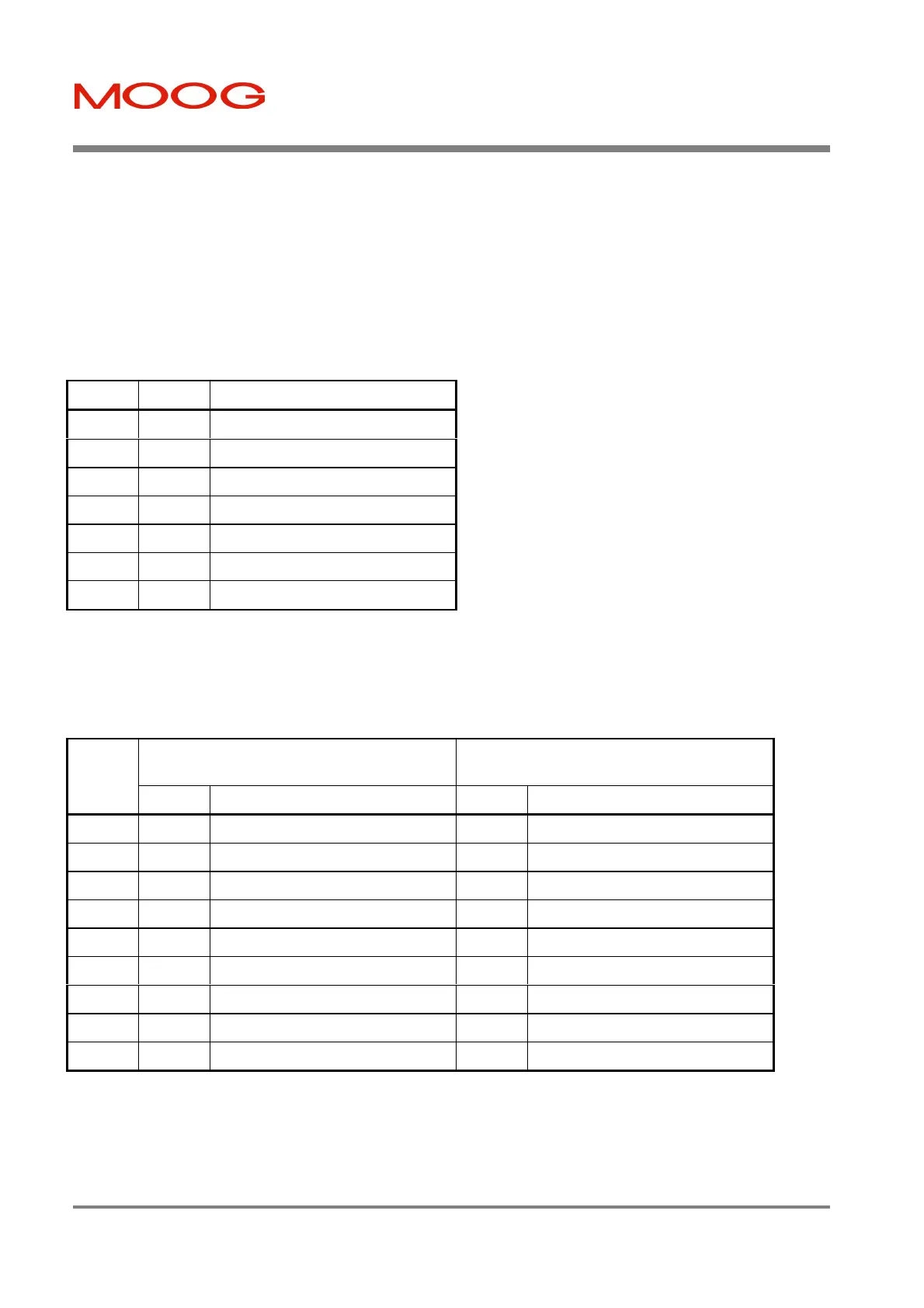

Byte Value Meaning

1 06 Length of command

2 00 Address

3 01 Command (read param)

4 P0 Param no (least significant)

5 P1 Param no (most significant)

6 SZ Parameter size (2/4)

7 CK Checksum

T200 Acknowledgement to Monitor Parameter

The acknowledge ‘data’ for a parameter read command is the ‘value of the parameter’ to be read. The value may be 2 or

4 bytes long, and will be transmitted in the order of least significant to most significant bytes:

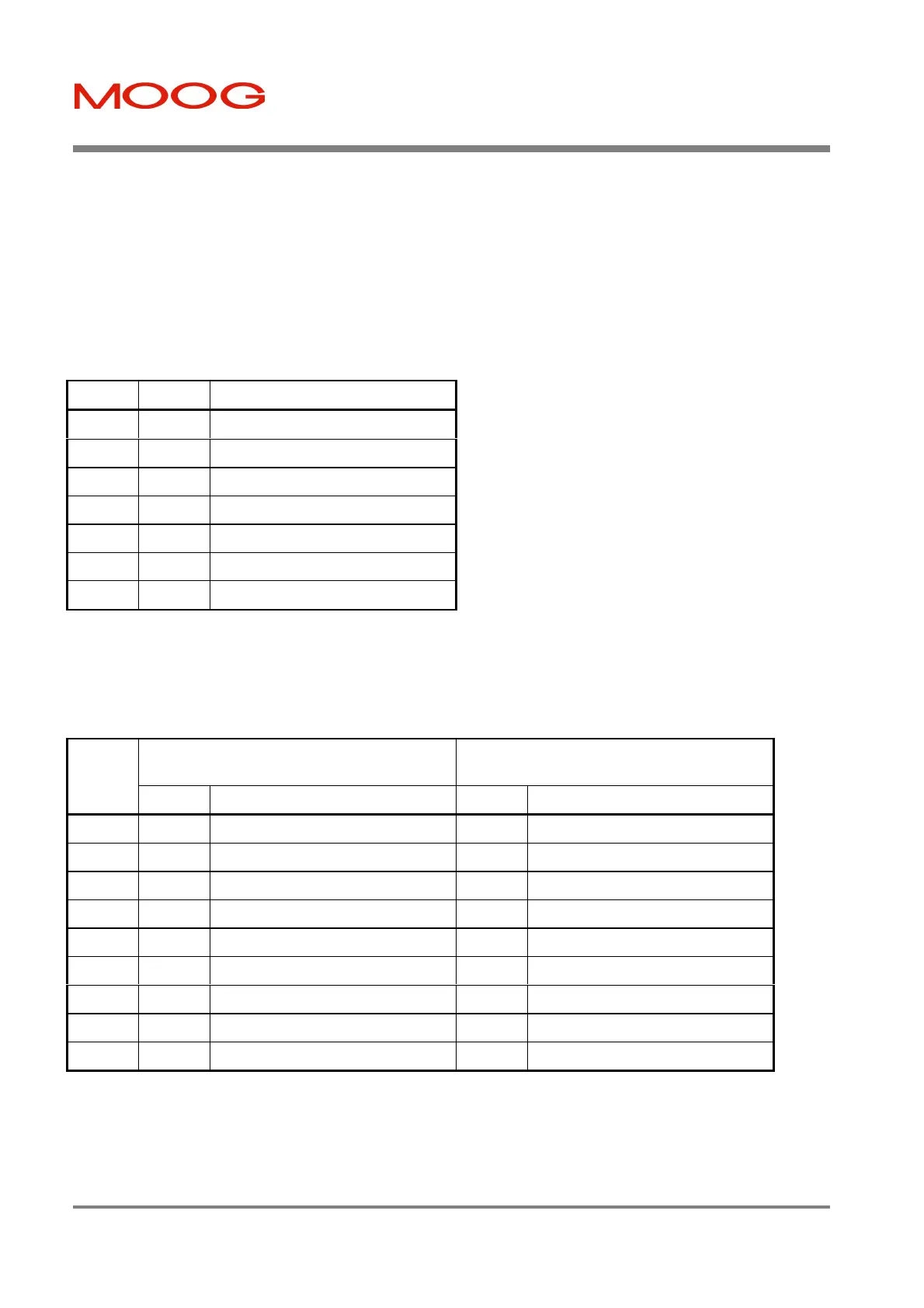

Acknowledge Two Byte Parameter Read

Command

Acknowledge Four Byte Parameter Read

Command

Byte Value Meaning Value Meaning

1 06 Length of command 08 Length of command

2 128 Address 128 Address

3 01 Command (read param) 01 Command (read param)

4 02 Ack Status 02 Ack Status

5 D0 Param val (least significant) D0 Param val (least significant)

6 D1 Param val (most significant) D1 Param val (next significant)

7 CK Checksum D2 Param val (next significant)

8 D3 Param val (most significant)

9 CK Checksum

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...