T200 User's Manual SECTION 10: TROUBLE-SHOOTING GUIDE

PAGE 10-28

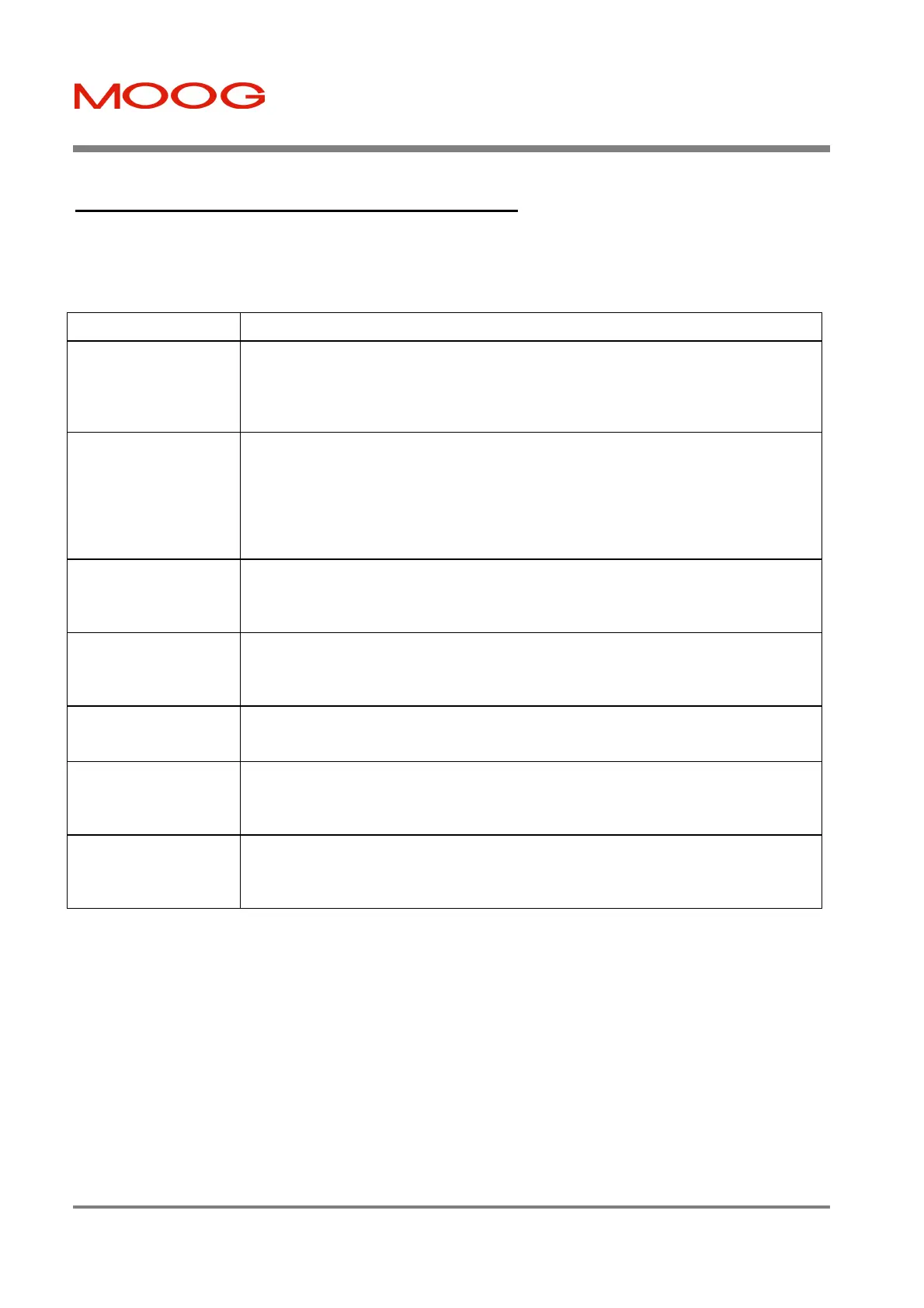

10.6.3 Problem: T200 Movement is not Smooth

The motor moves, but the movement is not smooth.

Table 27: Causes of T200 lack of smoothness

Cause Check/[Correction]

Motor Phase(s)

Disconnected

A loss of a motor phase will cause a non-smooth torque to be applied to the motor.

[Disable the T200. Remove all power from the T200 and wait 5 minutes before attempting

re-connection. Check the motor power cable connections to TB8. Re-apply power to the

T200. Re-enable and try again to move the axis.]

Motor not mounted

correctly.

The motor may not be mounted correctly, such that it moves with respect to its mounting

flange during the movement.

[Disable the T200. Remove all power from the T200 and wait 5 minutes before attempting

re-connection. Check the motor mounting arrangements. Tighten all mounting

attachments and screws, bolts etc. so that motor movement is not restricted or impossible.

Re-apply power to the T200. Re-enable and try again to move the axis.]

Motor or Load

Bearings damaged

The motor or load bearings may have become worn or damaged.

[Check the motor and load bearings with all power removed. If the motor is damaged,

return it to Moog.]

Mechanical

Resonance

The mechanic elements of the coupling between motor and load, and the load itself, may

be flexible.

[Consult Moog Applications engineering for guidance on tuning.]

Shaft Misalignment

The motor and load shafts may be mis-aligned.

[Correct the alignment problem.]

Motor Damage

The motor resolver transducer may be damaged or faulty. The motor phases may have

partial or total short circuits.

[Return the motor to Moog.]

Coupling Damage

The coupling between the Moog motor and the load may be damaged. For example,

gearwheel teeth may be broken off.

[Replace the coupling mechanism.]

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...