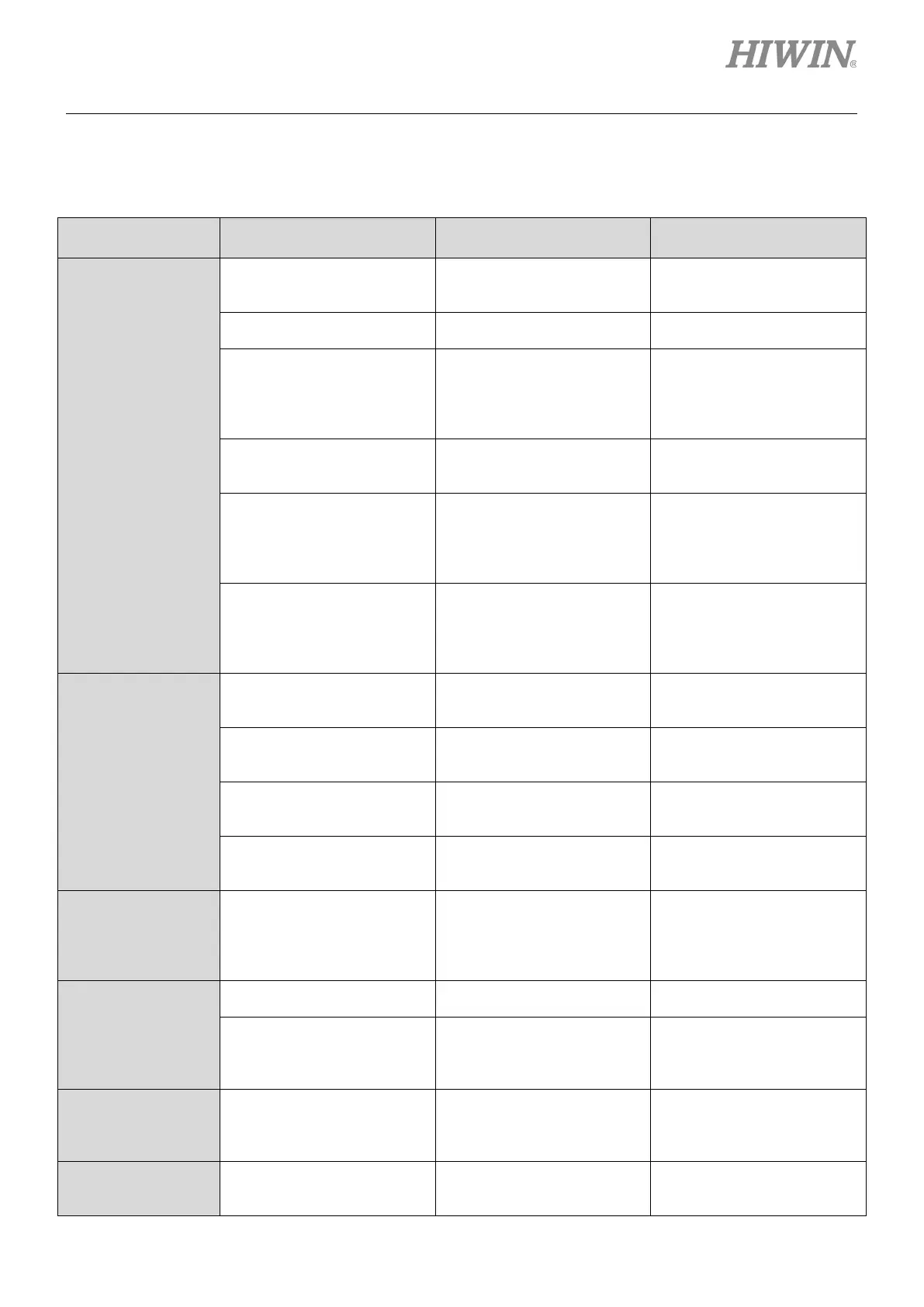

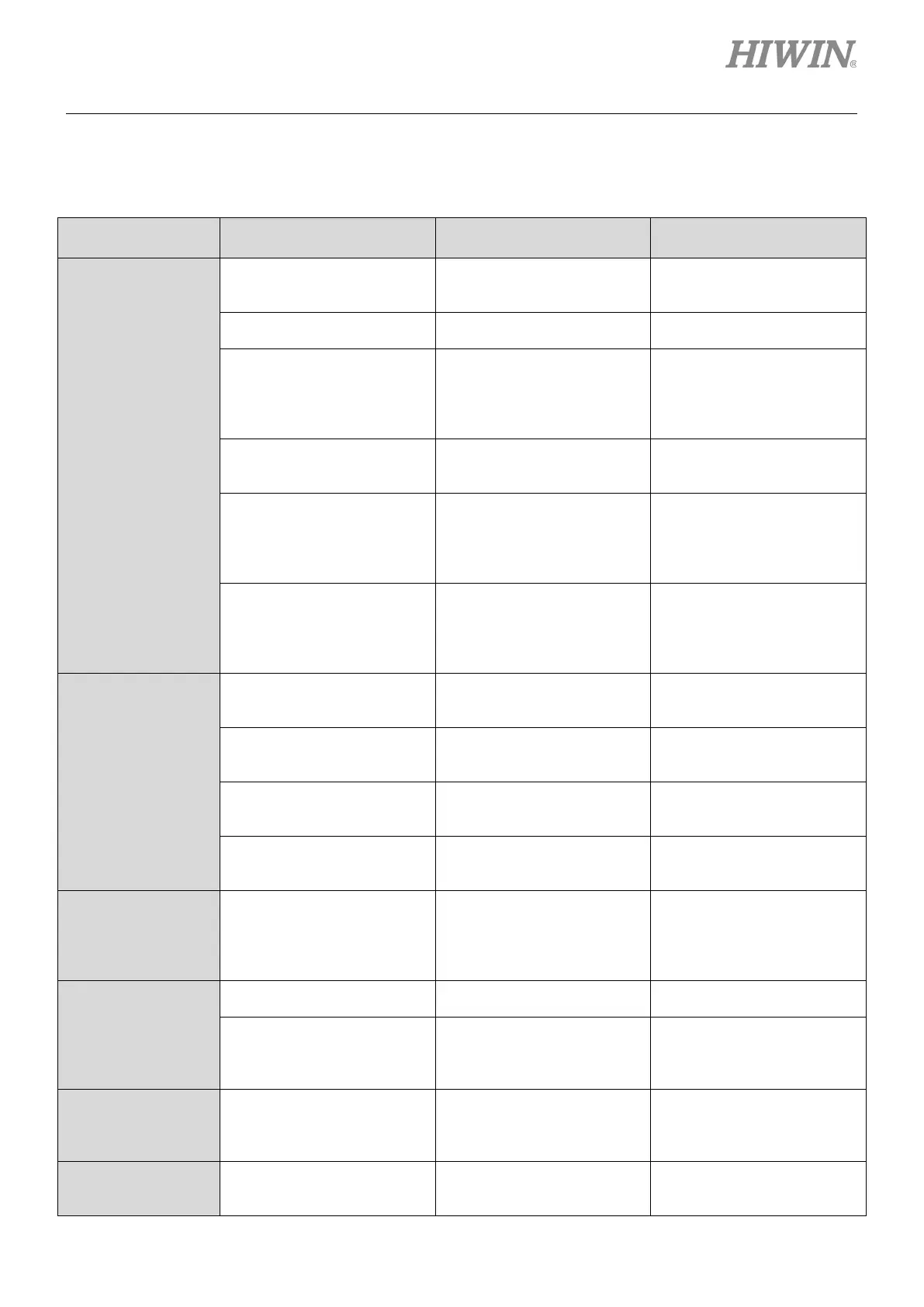

E1 Series Servo Drive User Manual Troubleshooting And Maintenance

HIWIN MIKROSYSTEM CORP. 13-17

13.3.2 Causes and corrective actions for warnings

Table13.3.2.1 Causes and corrective actions for warnings

Warning Number

And Warning Name

Cause Confirmation Method Corrective Action

AL.900

Position deviation

overflow

The wiring of the U, V or W

phase of the motor is

Check the wiring of the

motor power cable.

Check if the connection of

the motor power cable or

The servo gain of the servo

drive is too low.

Check if the servo gain of the

servo drive is too low.

Obtain proper servo gain by

auto tuning.

The inputting frequency of

command pulse is too high.

Decrease the inputting

frequency of command

pulse. Then start operation

again.

frequency of command pulse

or command acceleration.

Or adjust the electronic gear

is too high.

acceleration. Then start

acceleration/deceleration

The setting value of alarm

value for overflow position

deviation (Pt520 or Pt521) is

low when compared to the

Check if the setting value of

alarm value for overflow

position deviation (Pt520 or

Pt521) is appropriate.

Adjust the setting value of

alarm value for overflow

position deviation (Pt520 or

Pt521).

Servo drive malfunction N/A

Power on again. If the alarm

occurs again, it could be

servo drive malfunction,

please replace the servo

AL.910

Overload

encoder is poor or the

Check the wiring.

Check if the wirings of the

motor and encoder are

the detection value of

Check the detection value of

overload and motion

Re-calculate and adjust the

load and operating condition.

Overload occurs since the

motor cannot be operated

due to mechanical factor.

Check the motion command

and motor velocity.

Improve mechanical factor.

Servo drive malfunction N/A

malfunction, please replace

AL.923

Internal fan stop

The internal fan of the servo

drive stops operating.

Check if there is foreign

object inside the internal fan.

If the alarm occurs again

after the foreign object is

removed, it could be servo

drive malfunction, please

AL.930

Encoder battery

malfunction

The battery of absolute

encoder is abnormal.

Check if the battery voltage

is 5 V.

Change the battery or

encoder cable.

Encoder malfunction N/A

warning occurs again, it

could be motor malfunction,

please replace the motor.

Fieldbus

synchronous cycle

The synchronous cycle time

of Fieldbus communication

is unstable.

N/A

Increase Fieldbus

communication cycle time.

AL.944

System warning

internal program of the servo

N/A

Perform software reset or

power on the servo drive

Loading...

Loading...