Wheels and Tires: 2D-12

3) Adjust the drive chain slack after installing the rear

wheel. Refer to “Drive Chain Inspection and

Adjustment in Section 0B (Page 0B-17)”.

4) Tighten the rear axle nut (3) to the specified torque.

Tightening torque

Rear axle nut (a): 100 N·m (10.0 kgf-m, 72.5 lbf-

ft)

WARNING

!

After remounting the rear wheel, pump the

brake pedal a few times to check for proper

brake operation.

Rear Wheel Related Parts Inspection

B817H22406009

Refer to “Rear Wheel Assembly Removal and

Installation (GSF650/S/U/SUK7) (Page 2D-11)”.

Tire

Refer to “Tire Inspection in Section 0B (Page 0B-20)”.

Rear Brake Disc

Refer to “Rear Brake Disc Inspection in Section 4C

(Page 4C-7)”.

Wheel Damper

Refer to “Drive Chain Related Components in Section

3A (Page 3A-1)”.

Sprocket

Refer to “Drive Chain Related Parts Inspection in

Section 3A (Page 3A-5)”.

Dust Seal

Inspect the dust seal lip for wear or damage. If any

defects is found, replace the dust seal with a new one.

Refer to “Rear Wheel Dust Seal / Bearing Removal and

Installation (Page 2D-13)”.

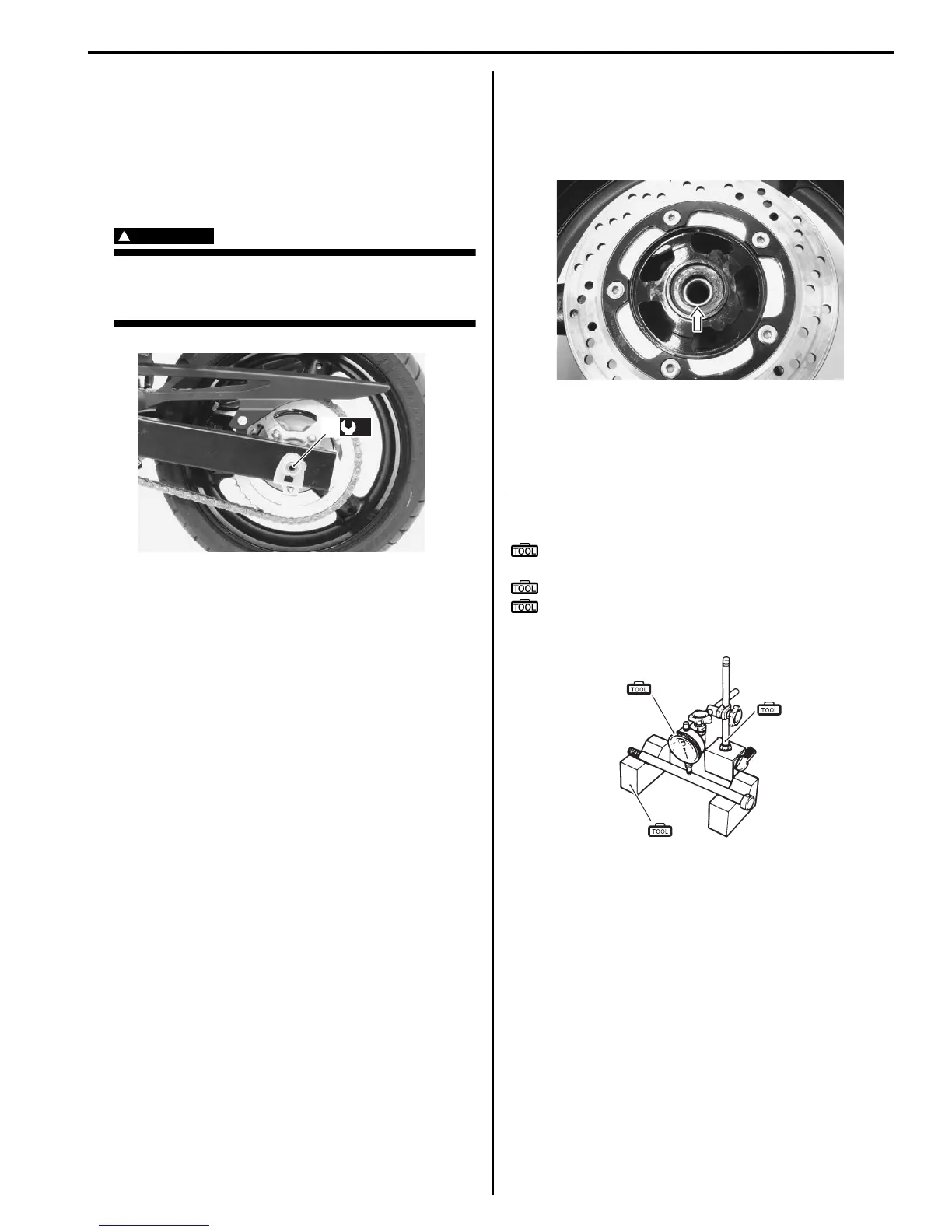

Wheel Axle

Using a dial gauge, check the wheel axle for runout, If

the runout exceeds the limit, replace the axle shaft.

Wheel axle runout

Service limit: 0.25 mm (0.010 in.)

Special tool

(A): 09900–20607 (Dial gauge (1/100 mm, 10

mm))

(B): 09900–20701 (Magnetic stand)

(C): 09900–21304 (V-block (100 mm))

Wheel

Inspect the wheel in the following procedures:

1) Remove the brake pads. Refer to “Rear Brake Pad

Replacement in Section 4C (Page 4C-2)”.

2) Make sure that the wheel runout checked as shown

does not exceed the service limit. An excessive

runout is usually due to worn or loosened wheel

bearings and can be reduced by replacing the

bearings. If bearing replacement fails to reduce the

runout, replace the wheel.

(a)

3

I717H1240028-01

I717H1240029-01

(A)

(B)

(C)

I649G1230034-03

Loading...

Loading...