2-sided Adhesive Pressure Seal

CCaauuttiioonn:: Do not use envelopes with a 2-sided adhesive pressure seal design. This envelope style can

cause damage to the fuser.

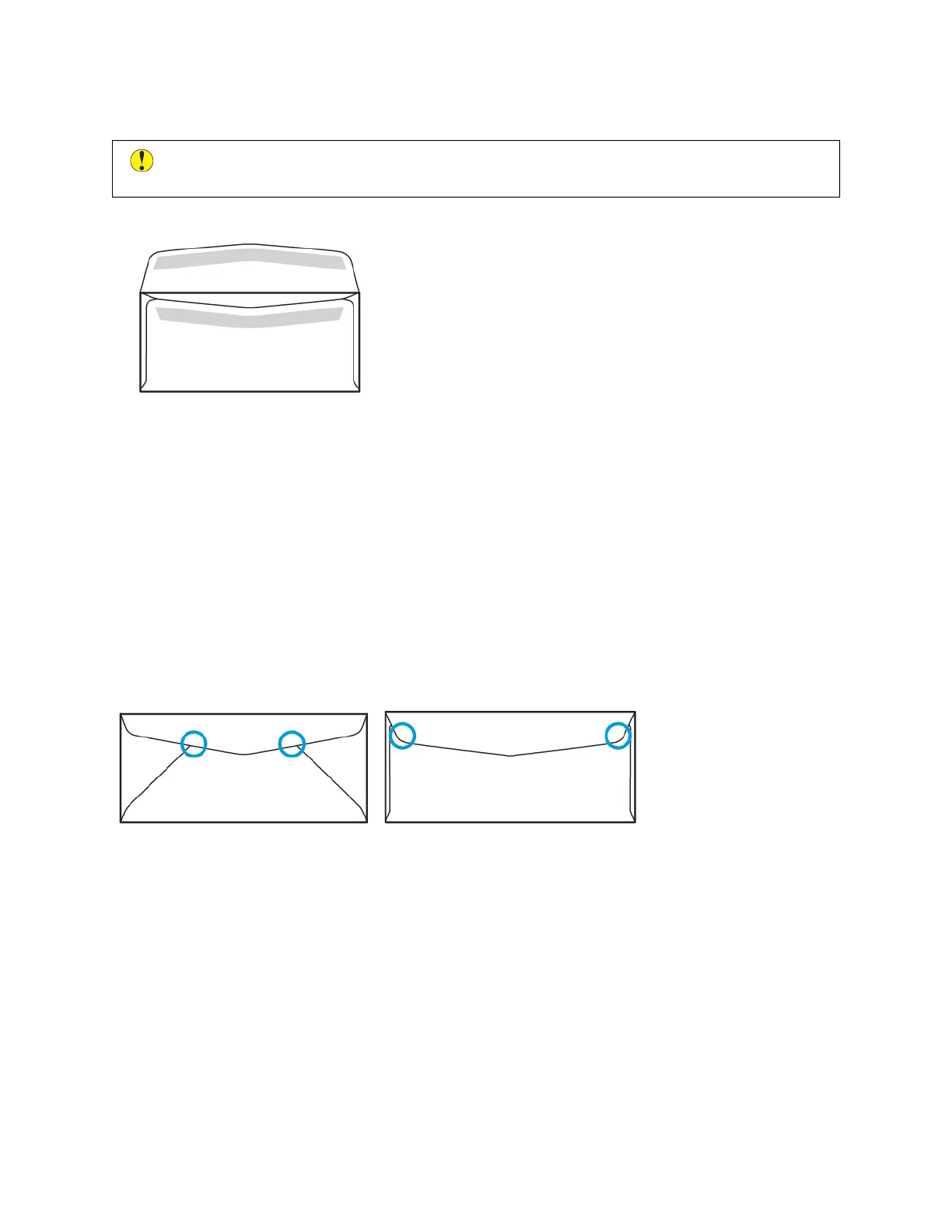

Envelope Design Considerations

When you select envelopes, be aware that the physical design and quality of the envelope can impose limitations

on print quality and handling.

The multiple surfaces that pass through the printer can present a challenge for envelope printing. For example,

most envelopes require that the printer transfers toner onto a surface that has two, three, or four layers of thickness.

When the envelope flaps are closed, a typical envelope has four layers of media in multiple locations. The

illustration below shows two different envelope designs. The blue circles indicate the locations where four layers of

media overlap.

In most cases, the printer is capable of transferring toner successfully onto thick media. However, tests have

concluded that the location of the overlapping layers can create pressure points in certain areas. These pressure

points can result in a void of pressure in other areas of the envelope. This phenomenon is illustrated in the next

section.

RECOMMENDATIONS FOR SPECIFIC ENVELOPE SIZES

Some limited testing was done with the following envelope sizes. Good results were achieved, with the exception of

wrinkling on the largest sizes, as noted in the Potential Issues section.

US:

186

Xerox

®

PrimeLink

®

B9100/B9110/B9125/B9136 Copier/Printer User Guide

Paper and Media

Loading...

Loading...