4 - 20

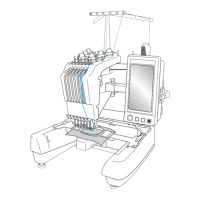

Adjustment Needle bar rising length and needle space adjustment

1. Enter the test mode, and press [MAIN BOARD TEST MODE] and then [NEEDLE SPACING].

2. Press [[SPACING] POSITION]]. The reference needle bar for rising length adjustment is selected and the needle

bar case final assembly moves.

3. Press [CLOSE] and then [SENSOR TEST], and rotate the pulley manually until the numerical value for [MAIN

MOTOR ANGLE] is "199."

4. Loosen the 3 screws

1

, adjust the needle bar rising length and the needle space, and tighten the 3 screws

1

.

5. Check the needle bar rising length and the needle space for the other 5 needle bars.

*Key point

• Pressing [←] and [→] selects the other needle bars.

1

Torque

0.59 - 0.78 N-m

Foot set screw

4.46

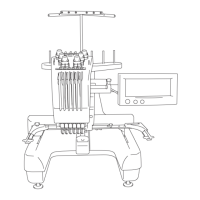

Color;

The right end of the

needle matches the

rotating hook's tip when

the value of [MAIN

MOTOR ANGLE] is 199

(approx. 2 mm).

(Technical standard:

The right end of the

needle must match the

rotating hook's tip when

the needle bar is raised

1.8 - 2.2 mm from the

bottom point.)

1

1.8 -

The clearance between the

needle and rotating hook's

tip in the back/forth direction

should be 0.2 mm or less.

Rotary hook point

Needle gap

0.2mm

Loading...

Loading...