P44x/EN AP/Hb

MiCOM P40 Agile P442, P444

(AP) 5-1

4.9.1 Time constant characteristic

4.9.1.1 Single time constant characteristic

This characteristic is the recommended typical setting for line and cable protection. The

thermal time characteristic is given by:

exp(-t/τ) = (Ι

2

– (k.Ι

FLC

)

2

) / (Ι

2

– Ι

P

2

)

Where:

t = Time to trip, following application of the overload current, Ι;

τ = Heating and cooling time constant of the protected plant;

Ι = Largest phase current;

Ι

FLC

= Full load current rating (relay setting ‘Thermal Trip’);

k = 1.05 constant, allows continuous operation up to < 1.05 Ι

FLC

.

Ι

P

= Steady state pre-loading before application of the overload.

The time to trip varies depending on the load current carried before application of the

overload, i.e. whether the overload was applied from «hot» or «cold».

The current setting is calculated with Thermal Trip = Permissible continuous loading of the

plant item/CT ratio.

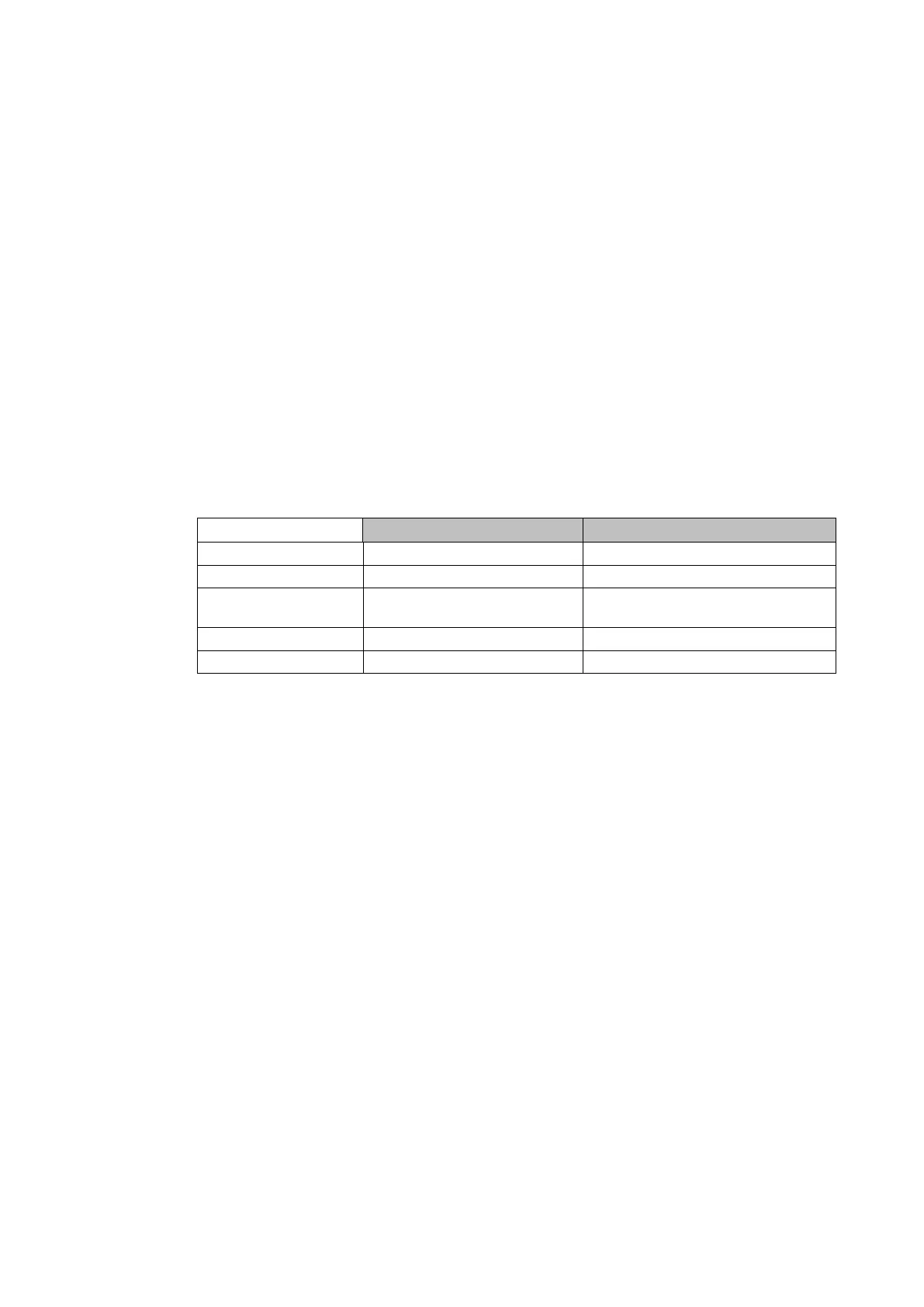

Typical time constant values are given in the following table.

Time constant 1

(mN)

Limits

Air-core reactors 40

Capacitor banks 10

Overhead lines 10

Cross section ≥ 100 mm

2

Cu or 150 mm

2

Al

Cables 60 – 90 Typical, at 66 kV and above

Busbars 60

Table 9: Typical protected plant thermal time constants

4.9.1.2 Dual time constant characteristic (Typically not applied for MiCOMho P443)

This characteristic is used to protect oil-filled transformers with natural air cooling (e.g. type

ONAN). The thermal model is similar to that with the single time constant, except that two

time constants must be set. The thermal curve is defined as:

0.4 exp(-t/τ1) + 0.6 exp(-t/τ2) = (Ι

2

– (k.Ι

FLC

)

2

) / (Ι

2

– Ι

P

2

)

Where:

τ1 = Heating and cooling time constant of the transformer windings;

τ2 = Heating and cooling time constant for the insulating oil.

For marginal overloading, heat will flow from the windings into the bulk of the insulating oil.

Therefore, at low current, the replica curve is dominated by the long time constant for the oil.

This provides protection against a general rise in oil temperature.

For severe overloading, heat accumulates in the transformer windings, with little opportunity

for dissipation into the surrounding insulating oil. Therefore, at high current, the replica curve

is dominated by the short time constant for the windings. This provides protection against hot

spots developing within the transformer windings.

Overall, the dual time constant characteristic provided within the relay serves to protect the

winding insulation from ageing, and to minimise gas production by overheated oil. Note,

however, that the thermal model does not compensate for the effects of ambient temperature

change.

The current setting is calculated wuth Thermal Trip = Permissible continuous loading of the

transformer / CT ratio.

Typical time constants:

Loading...

Loading...