5 Motor control & motor settings

5.11 Setting control loops

123

Lenze · i700 servo inverter · reference manual · DMS 3.0 EN · 06/2016 · TD06

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.11.3 Setting the speed controller

For the automatic calculation of the gain and the reset time, the "Speed controller: Calculate

controller parameters" function is provided via object 0x2822

(or 0x3022 for axis B). This serves to

calculate speed controller starting values. To ensure optimal operation, we recommend a manual

follow-up optimisation.

The following equations apply to a rigid system. For elastic systems and systems with backlash, the

gain is reduced. The moment of inertia required for the calculation usually consists of the moment

of inertia of the motor and the load moments of inertia transformed to the motor side.

Special case of the linear motor

Here a re-calculation from a linear system to a rotary system must be made. Therefore, via the

feedback system a degree of freedom results for the determination of the number of pole pairs.

• For a rotary system, the number of pole pairs specifies the ratio of electrical and mechanical

revolution, the number of encoder increments being defined via one mechanical revolution.

• In the case of a linear system, the user is free to decide for which length he or she wants to

specify the number of encoder increments. Usually, the number of increments is given for a pole

distance or for the total length of the linear scale. If the number of increments = "number of

increments for one pole distance" is selected, a motor with the number of pole pairs zp = 1 is

created.

The effective moment of inertia for a linear motor can be calculated according to the following

equations. With this J value, the equations shown above can be used to calculate the speed

controller gain and reset time.

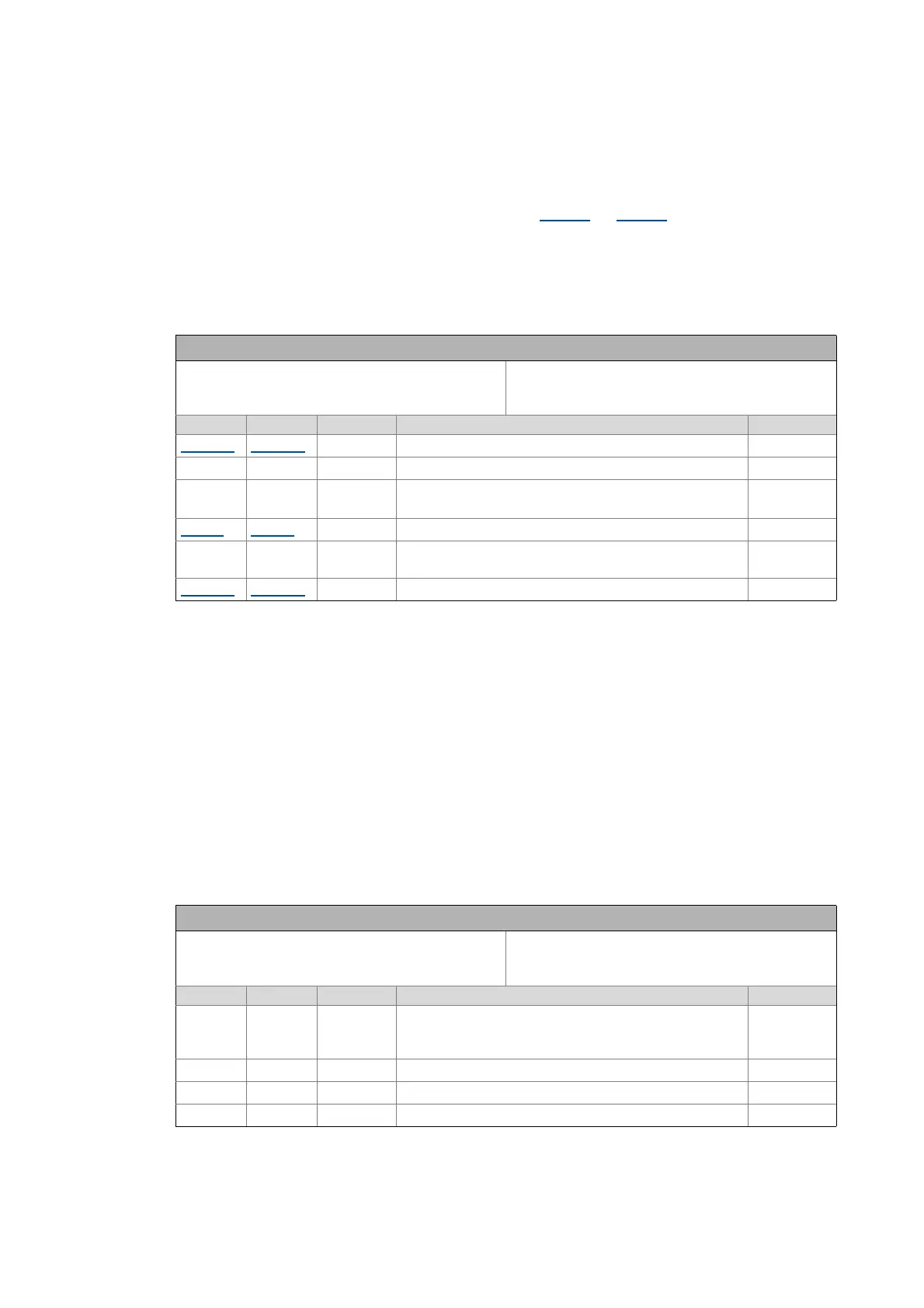

Equations for calculating the gain and the reset time (applicable for rigid systems)

Axis A Axis B Symbol Description Dimension unit

0x2900:1 0x3100:1 V

p

Speed controller gain Nm/rpm

- - J Moment of inertia = J

Motor

+ sum (J

Load

)kg m

2

- - a Unit for the phase reserve

(recommendation: a = 4 ≡ phase reserve of 60°)

0x2904

0x3104 T

filter

Actual speed value filter time constant s

-- T

current

controller

Equivalent time constant of the current control loop

= 0.0005 s (500 μs)

s

0x2900:2

0x3100:2 T

n

Speed controller reset time s

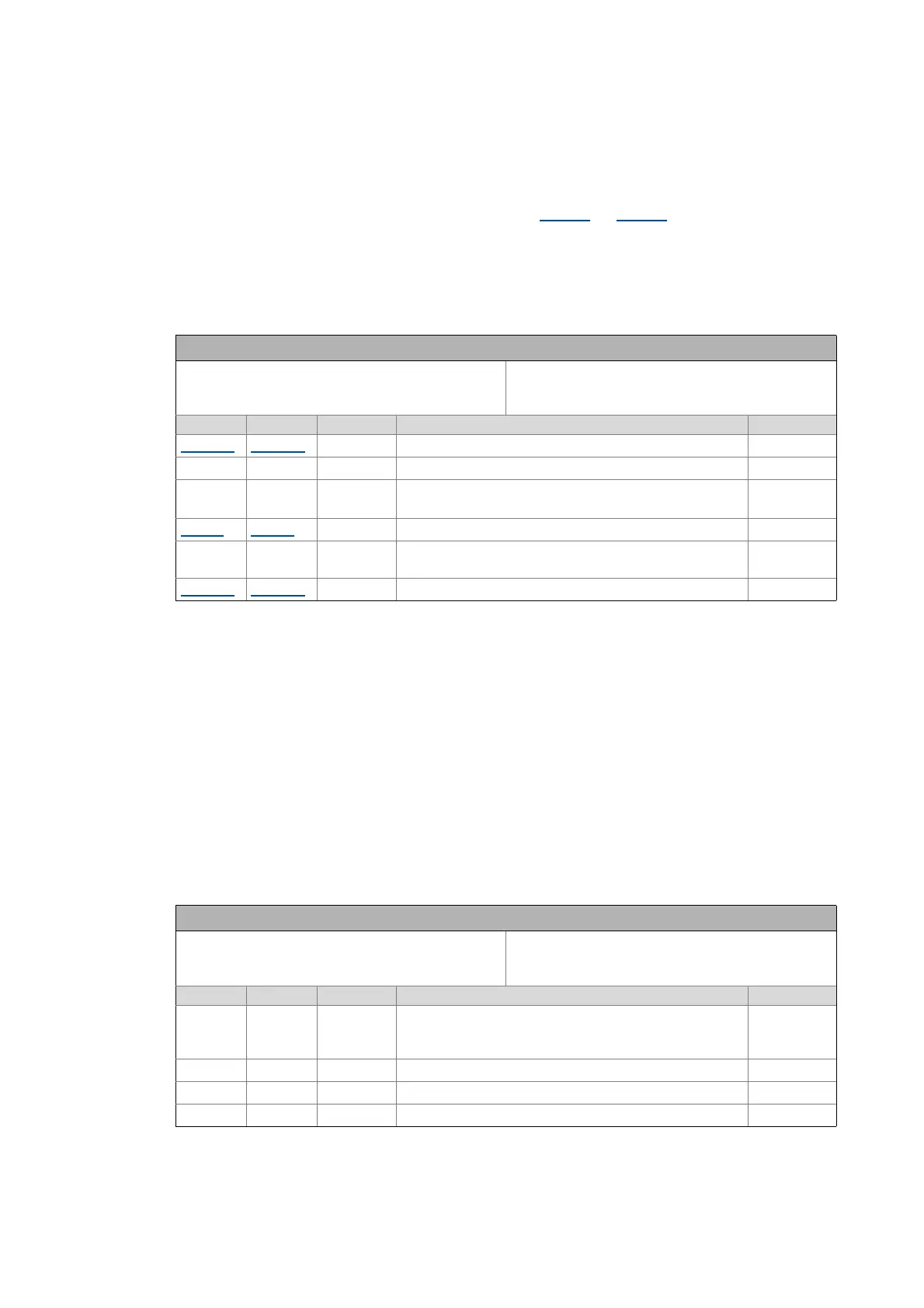

Equations for calculating the effective moment of inertia for the linear motor

Axis A Axis B Symbol Description Dimension unit

- - s Length on which the specification for the number of encoder

increments is based.

(e.g. per pole distance or total length)

m

-- 2τ

pole pair

Pole distance of the permanent magnets, pole pair width m

- - J Moment of inertia = J

Forcer

+ J

Slide

+ J

Load

kg m

2

- - m Moving mass = m

Forcer

+ m

Slide

+ m

Load

kg

V

p

J

aT

Filters

T

Current controller

+()⋅

----------------------------------------------------------------------------

2π

60

------ -

⋅=

T

n

a

2

T

Filters

T

Current controller

+()⋅=

zp Integer

s

2τ

Pole pair

------------------------

=

Jm

zp 2τ

Pole pair

⋅

2π

-----------------------------------

2

⋅=

Loading...

Loading...