Loading...

Loading...

Do you have a question about the Lenze i700 and is the answer not in the manual?

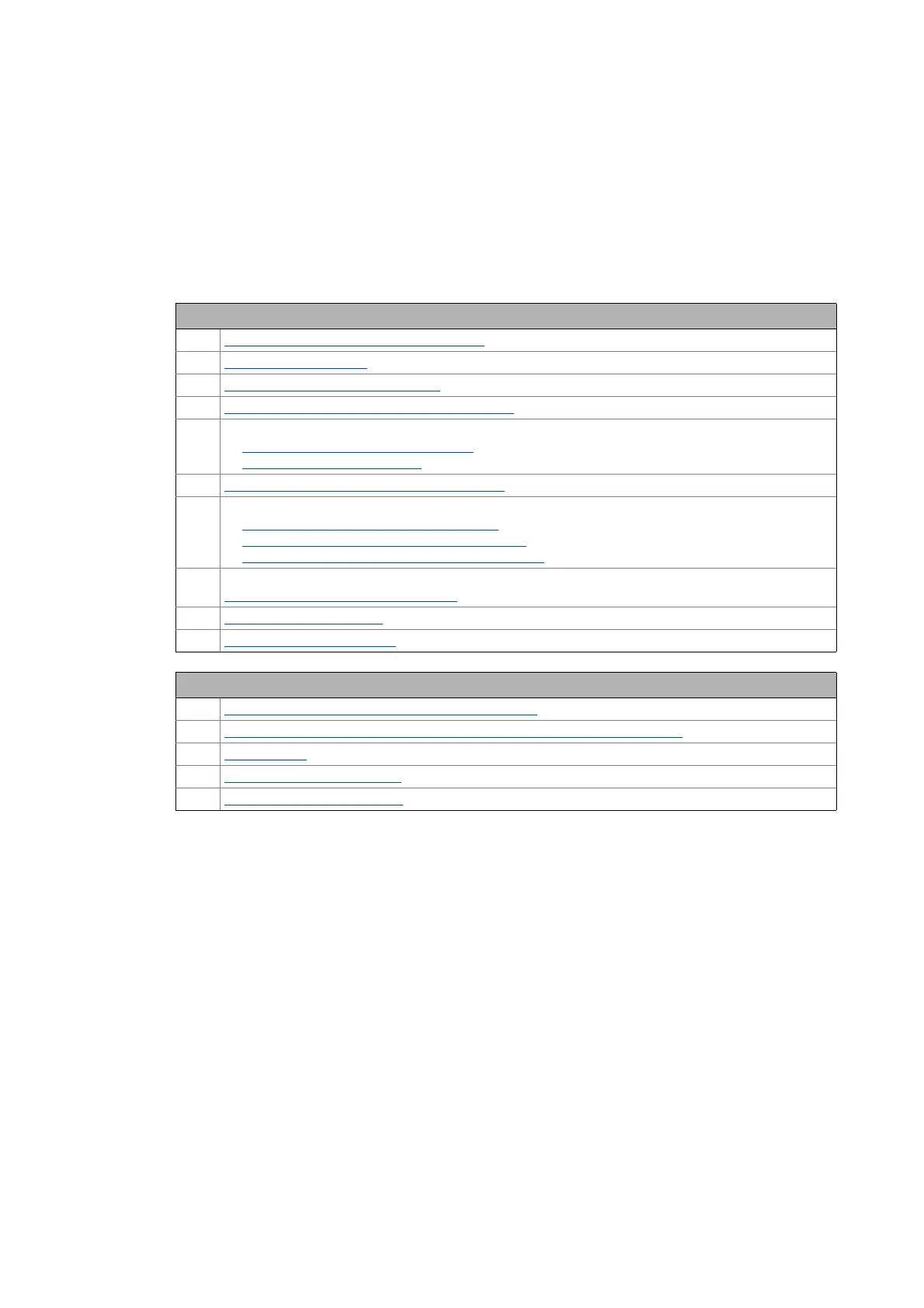

| Control Type | Vector control, V/f control |

|---|---|

| Safety | STO (Safe Torque Off) |

| Protection Class | IP20 |

| Frequency | 50/60 Hz |

| Communication Interfaces | CANopen |

| Cooling | Air cooled |

| Protection Features | Overvoltage, Undervoltage |

| Ambient Temperature | -10°C to +45°C |

| Frequency Range | 0 Hz to 300 Hz |

| Supply Voltage | 3-phase AC |

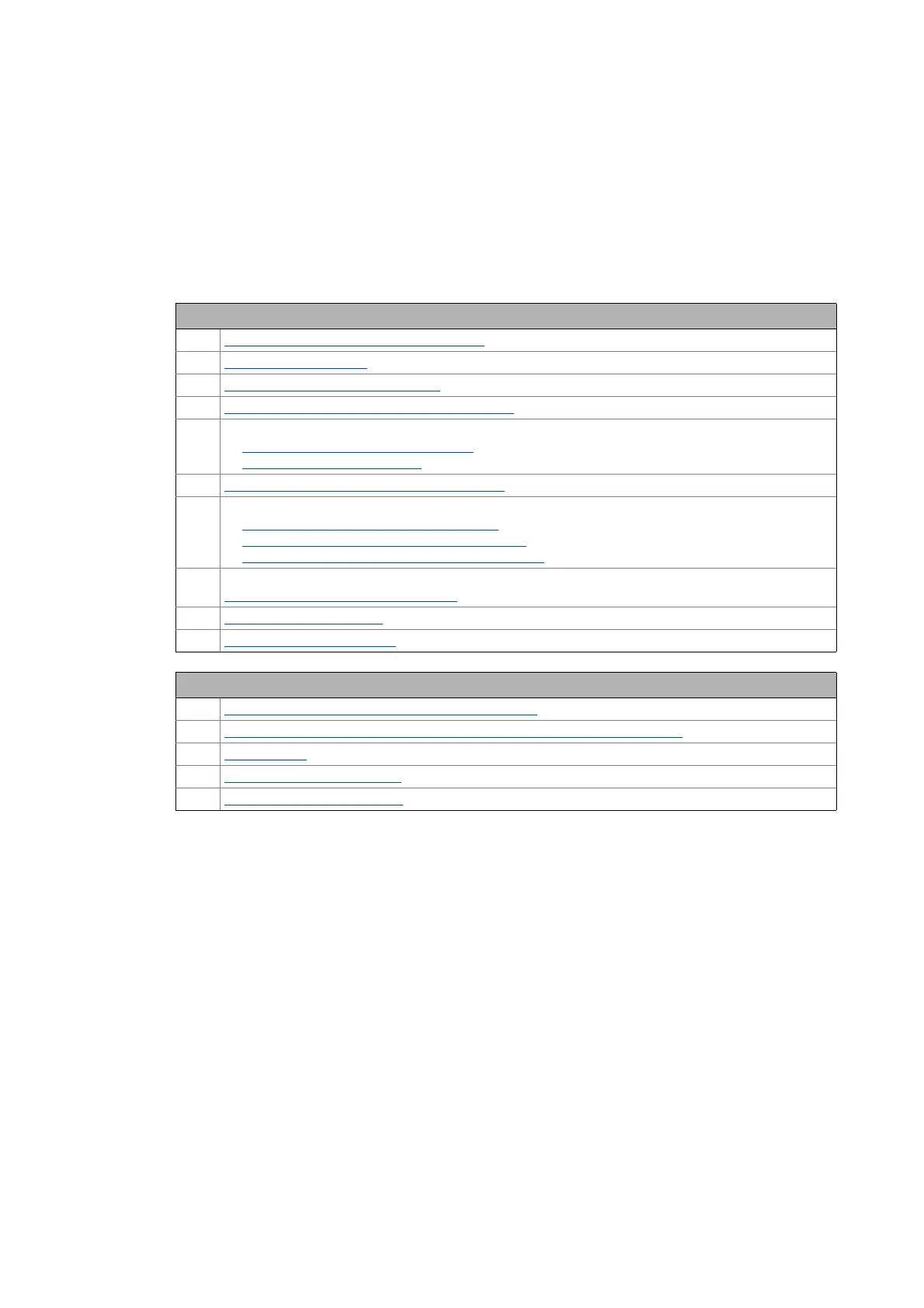

Details the exchange of configuration data between the controller and the servo inverter during system acceleration.

Explains the two types of parameter sets provided for storage and their differences.

Explains the process of establishing communication and the configuration data exchanged.

Describes the Ethernet over EtherCAT protocol for sending Ethernet telegrams via EtherCAT.

Details the three EtherCAT monitoring modes for error detection.

Explains the monitoring of DC-bus voltage for undervoltage and overvoltage conditions.

Provides an overview of commissioning steps for different control modes and motor types.

Details functions for automatic parameter calculation and setting for quick commissioning.

Explains how to check motor wiring and function using manual test modes.

Describes the manual operation mode via engineering tools for wiring checks.

Explains the different modes for open-loop/closed-loop motor control supported by the i700 servo inverter.

Guides on setting motor model parameters for servo control.

Explains how to set the feedback system for servo control after setting motor parameters.

Details the setting of different control loops subsequent to motor parameterization.

Covers the parameterization of the V/f characteristic control for motor voltage determination.

Explains objects that control the servo inverter states and operating modes.

Explains the cyclic sync position mode, providing quick position following with speed/torque feedforward control.

Details the monitoring of device utilisation to protect the power section and other components.

Detects motor thermal utilisation by calculating thermal motor utilization from detected motor currents.

Monitors position and velocity errors against set tolerances.

Lists possible error codes, their causes, remedies, and responses for the i700 servo inverter.