Cooling circuit and coolant properties

13.1 Cooling circuit requirements

Booksize Power Units

Manual, (GH2), 07/2016, 6SL3097-4AC00-0BP8

773

Cooling circuit configuration

The liquid-cooled power units are designed to be connected in parallel to the cooling circuit.

The pressure drop in the joint supply and return lines is to be kept at negligible levels by

choosing a sufficiently large pipe diameter. The intake has differential pressure p with

respect to the return. This pressure is usually generated by a pump.

The pressure of a pump depends on the flow rate. Therefore, depending on the number of

connected components, a different pressure is obtained. At the minimum differential

pressure p1 (measured between the supply and return lines of the individual component),

the volume of coolant required to enable the component to achieve its rated power or rated

current is to flow through each component. At the maximum differential pressure p2

(measured between the supply and return lines of the individual component), the volumetric

flow must not result in damage to the component, for example, by means of cavitation. If

necessary, pressure reducing valves such as baffle plates will have to be installed in the

piping; these must be easy to access, clean, and/or replace.

When the pump is switched off, static pressure occurs in the system. The static pressure can

be influenced by the primary pressure of the membrane expansion tank and should be at

least 30 kPa on the pump's suction side. If the static pressure is too low, there is the risk that

the pump will be damaged by cavitation when operational. Otherwise, minimum pressure

values different than those specified by the pump manufacturer must be observed. When

components are installed at different heights, the geodesic pressure caused by the height

difference must be taken into account (1 m height difference corresponds to 10 kPa).

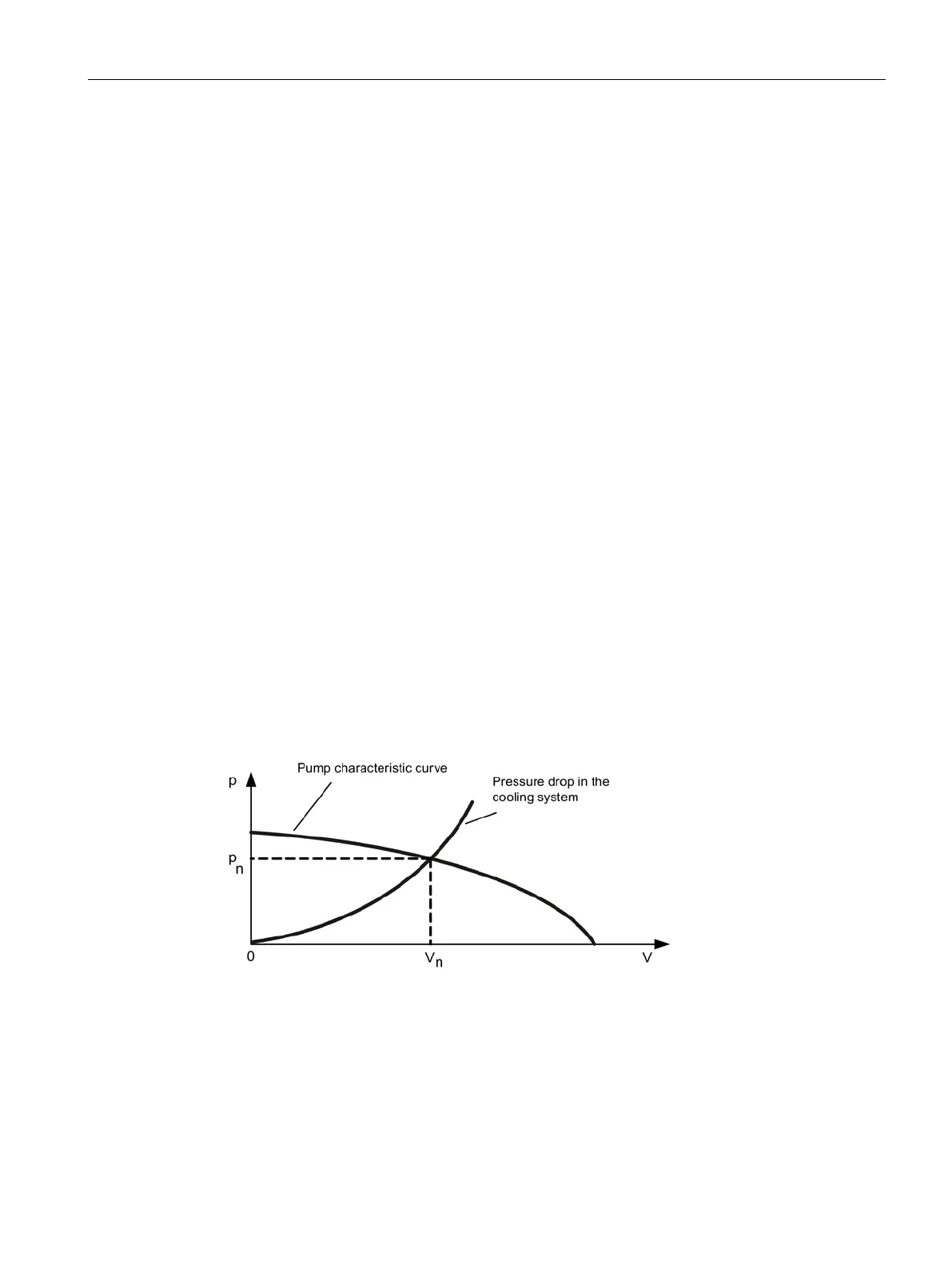

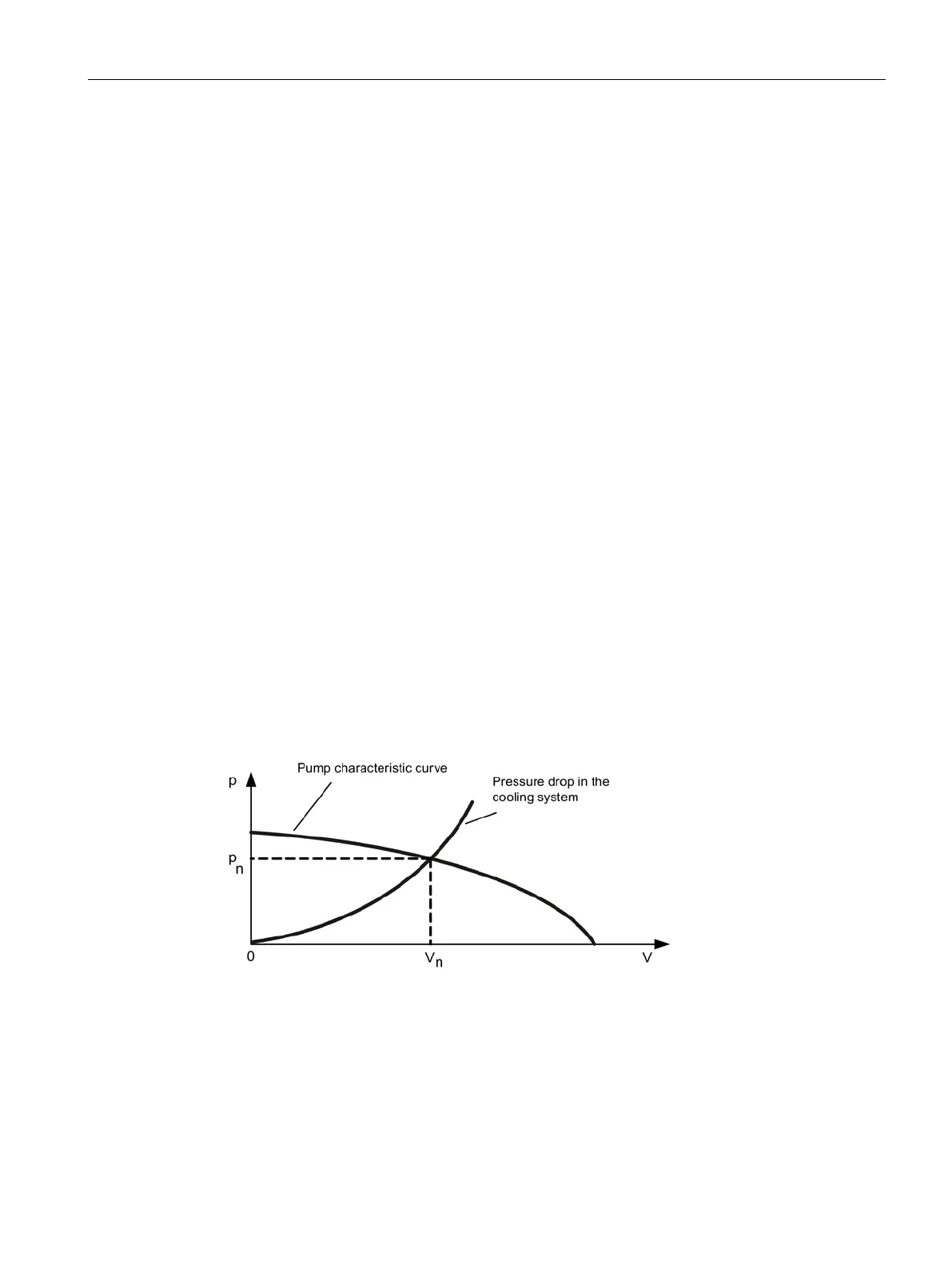

When the pump is switched on, a (location-dependent) flow pressure is present in the

cooling circuit, which must be determined from the pump characteristic curve and the

volume-flow-dependent pressure drop. The pressure drop in the filter and, if applicable, an

additional pressure drop in the connection pipes must be added to the pressure drop of the

liquid-cooled power units (70 kPa for H

2

O). Up to 50 kPa must be added for the pressure

drop in a (contaminated) filter and in connection pipes. The intersection of the pump

characteristic curve and the pressure drop of the whole cooling system yields the volumetric

flow V

rated

of the coolant at this operating point.

Figure 13-1 Pump characteristic curve

Permissible system pressure

Loading...

Loading...