5-12

FUEL

AND LUBRICATION SYSTEM

INSPECTION

Check the following items

for any

damage

or

clogging.

If any

damages

are found, replace the

damaged

parts

with

new ones.

*

Pilot jet

*Main jet

*Main air jet

*

Pilot air jet

*

Needle jet air bleeding hole

*

Float

*

Needle valve

*

Jet needle

*

Valve seat

*

Piston valve

*

Starter (enricher) jet

*

O-ring

*

Throttle

valve

*

Diaphragm

*

Pilot outlet and by-pass ports

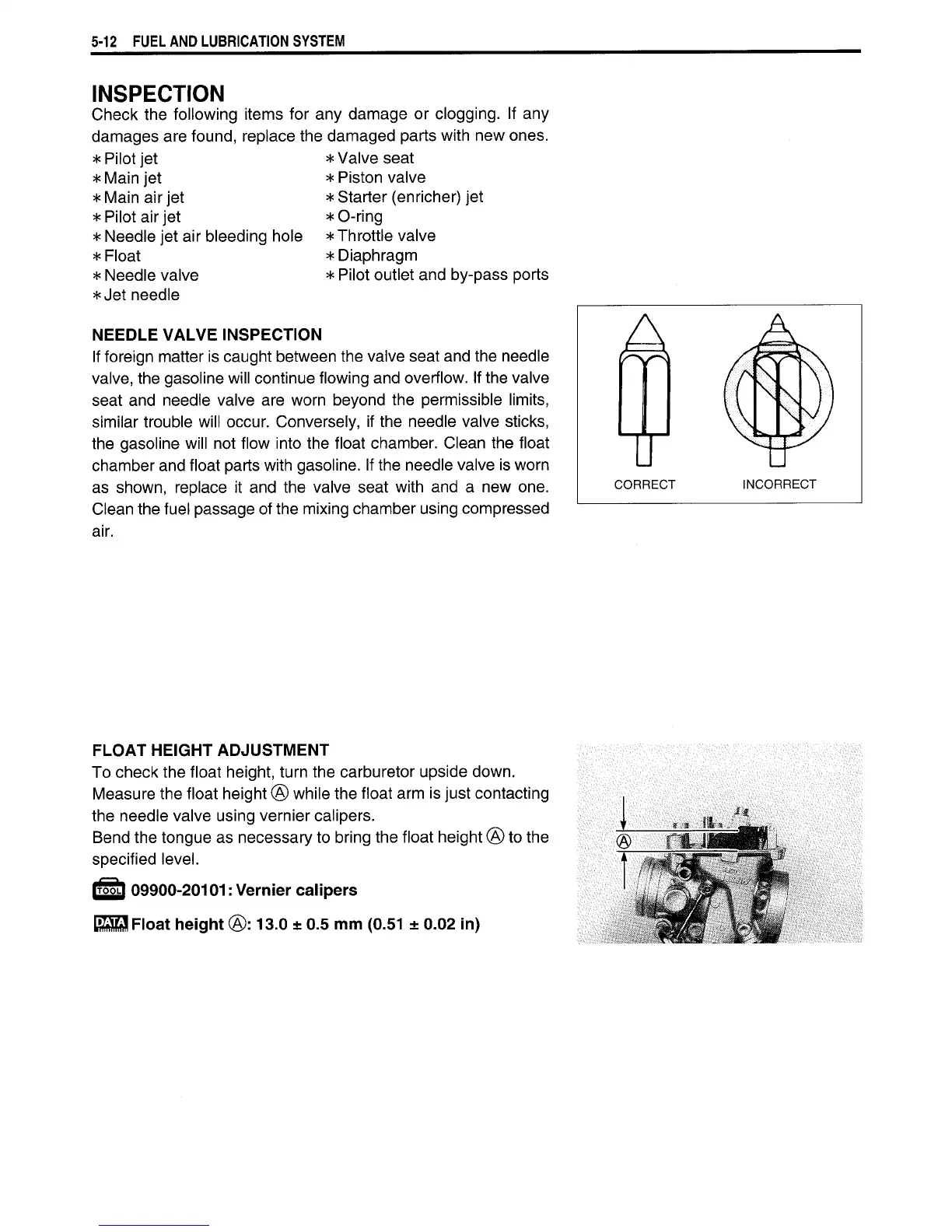

NEEDLE

VALVE INSPECTION

If

foreign matter is caught between the valve seat and the needle

valve, the gasoline

will

continue flowing and overflow. If the valve

seat

and

needle valve

are

worn

beyond

the

permissible

limits,

similar

trouble

will

occur. Conversely,

if

the needle valve

sticks,

the

gasoline

will

not flow into the float chamber.

Clean

the float

chamber and float parts

with

gasoline. If the needle valve is worn

as shown, replace

it and the

valve seat

with

and a new one.

Clean

the fuel

passage

of the mixing chamber using compressed

air.

u

CORRECT

INCORRECT

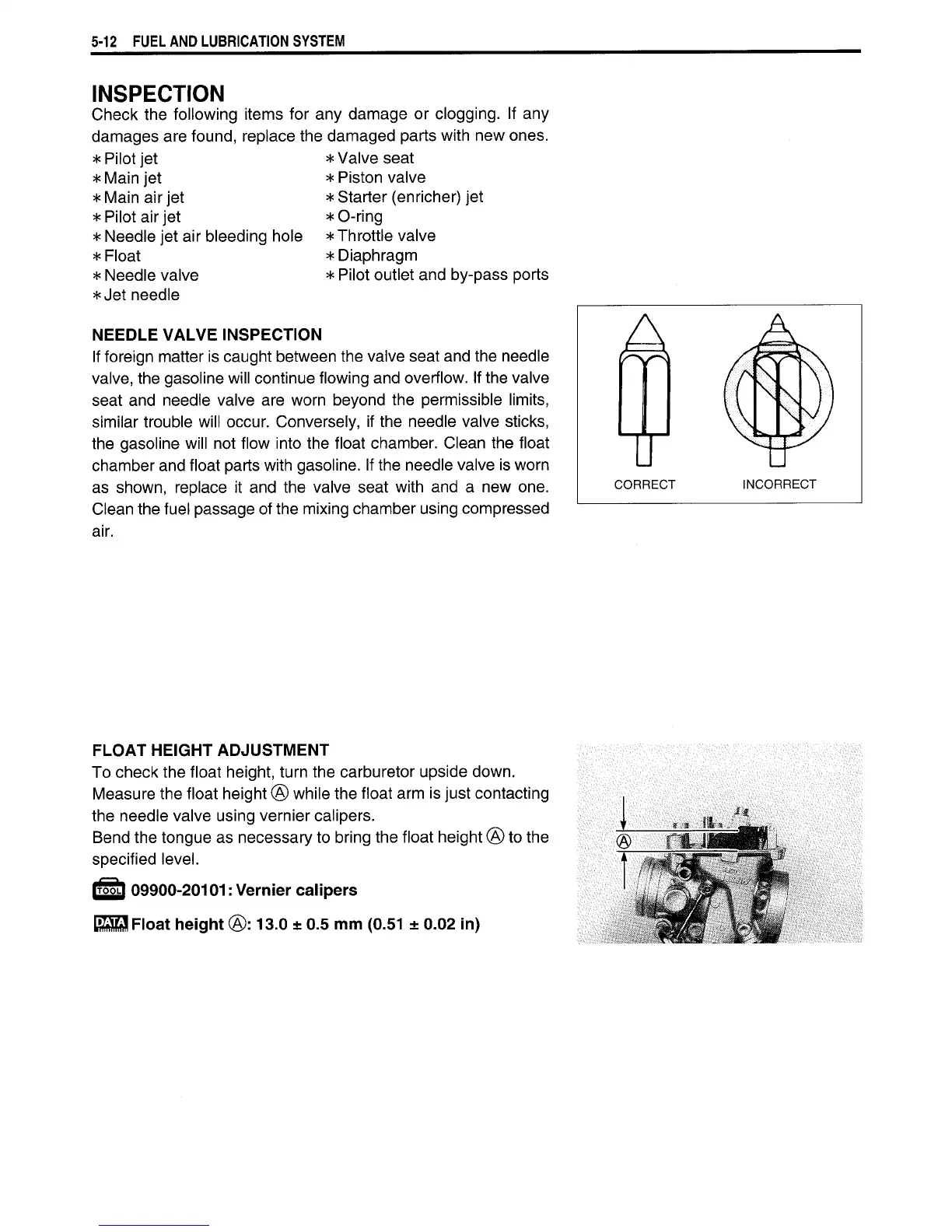

FLOAT

HEIGHT ADJUSTMENT

To check the float height, turn the carburetor upside down.

Measure

the float height

®

while the float arm is just contacting

the

needle valve using vernier calipers.

Bend

the tongue

as

necessary to bring the float height

®

to the

specified

level.

09900-20101:

Vernier calipers

RISES

Float

height

®: 13.0 ± 0.5 mm (0.51 ± 0.02 in)

Loading...

Loading...