ENGINE

3-25

•

Compress

the

valve springs

and

remove

the

valve

cotters

from the valve stem using the special

tools.

(T||]

09916-14510:

Valve spring compressor

09916-14910:

Attachment

09916-84511:

Tweezers

Remove

the valve spring retainer and valve springs.

Remove

the valve from the other side.

•

Remove

the oil seal

with

long-nose pliers.

•

Remove

the valve spring seat.

NOTE:

Removal

of valves completes ordinary disassembling work. If

valve guides have to be removed for replacement after inspect-

ing the related parts, carry out the

steps

shown in the valve

guide servicing.

CYLINDER

HEAD DISTORTION

Decarbonize the combustion chamber.

Check

the

gasket surface

of the

cylinder head

for

distortion

using

a

straightedge

and

thickness gauge. Take clearance

readings

at

several places.

If any

clearance reading exceeds

the

service

limit,

replace the cylinder head

with

a

new one.

(^)

09900-20803:

Thickness gauge

mm Cylinder head distortion

Service

Limit: 0.05 mm

(0.002

in)

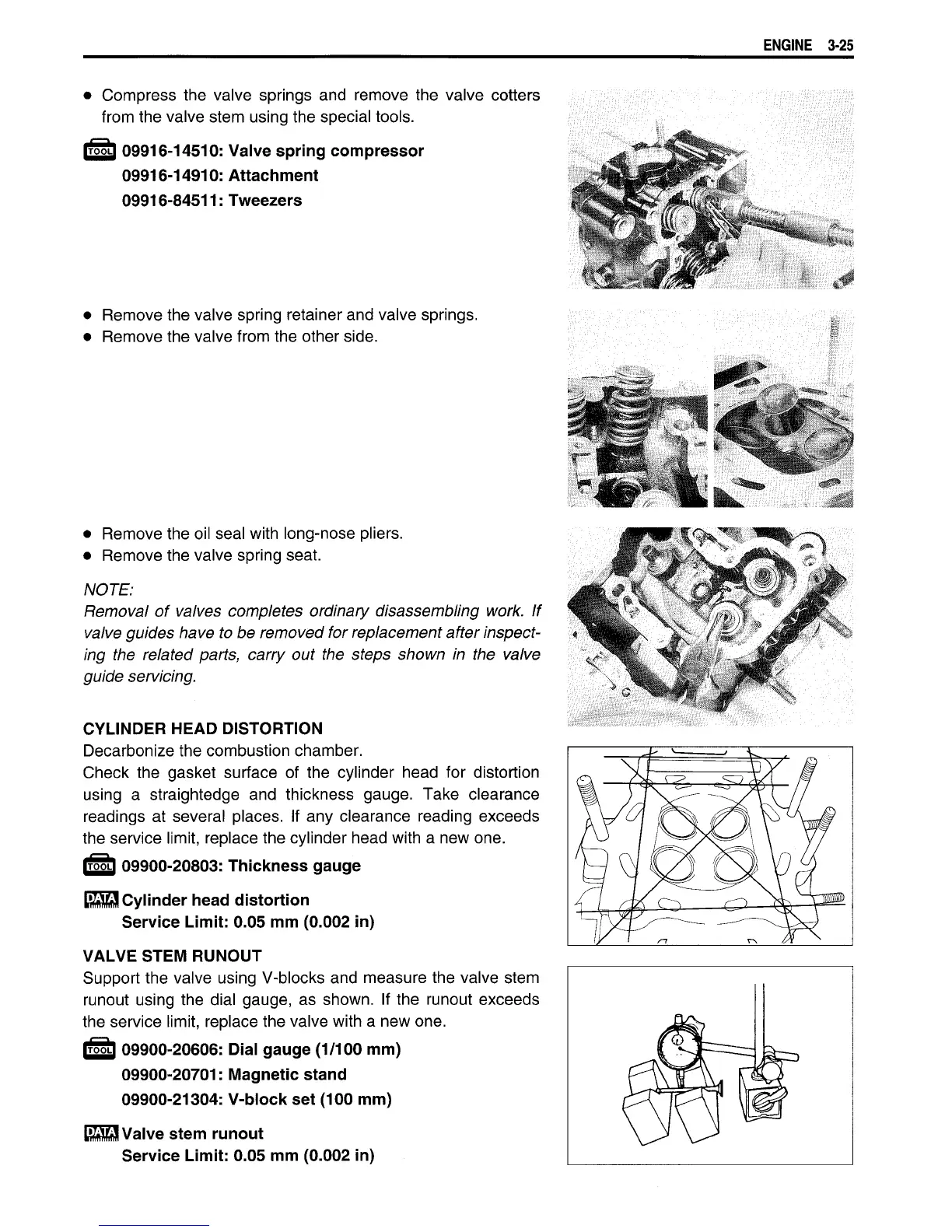

VALVE

STEM RUNOUT

Support the valve using V-blocks and measure the valve stem

runout using the dial gauge,

as

shown.

If

the runout exceeds

the

service

limit,

replace the valve

with

a

new one.

(T|5L]

09900-20606:

Dial gauge

(1/100

mm)

09900-20701:

Magnetic

stand

09900-21304:

V-block set (100 mm)

i^aq

Valve stem runout

Service

Limit: 0.05 mm

(0.002

in)

Loading...

Loading...