CYLINDER AND PISTONS

5-27

b. If out of specification, rebore or replace the

cylinder, and replace the piston and piston

rings as a set.

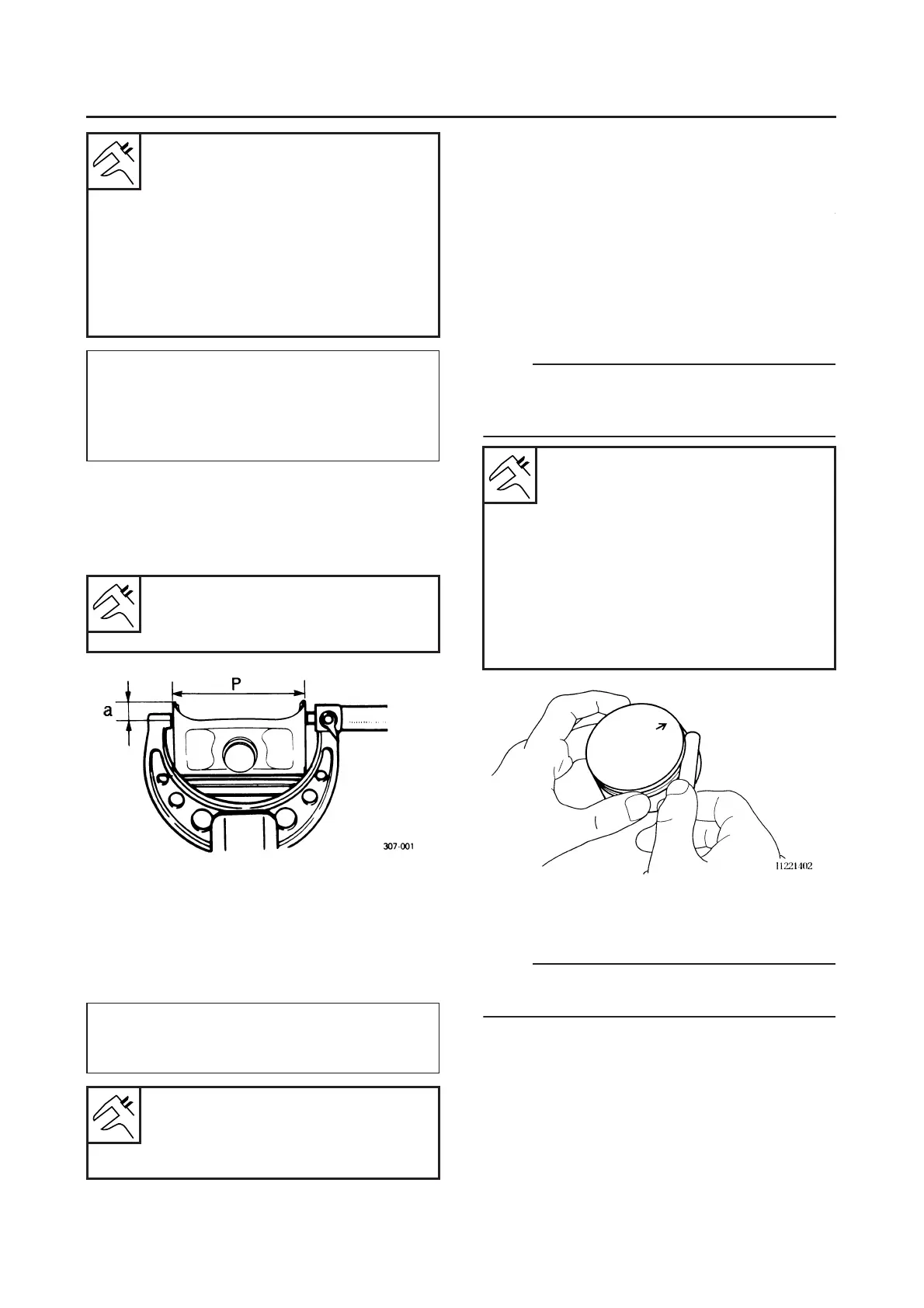

c. Measure piston skirt diameter “P” with the mi-

crometer.

d. If out of specification, replace the piston and

piston rings as a set.

e. Calculate the piston-to-cylinder clearance

with the following formula.

f. If out of specification, rebore or replace the

cylinder, and replace the piston and piston

rings as a set.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS24430

CHECKING THE PISTON RINGS

1. Measure:

● Piston ring side clearance

Out of specification → Replace the piston

and piston rings as a set.

NOTE:

Before measuring the piston ring side clearance,

eliminate any carbon deposits from the piston

ring grooves and piston rings.

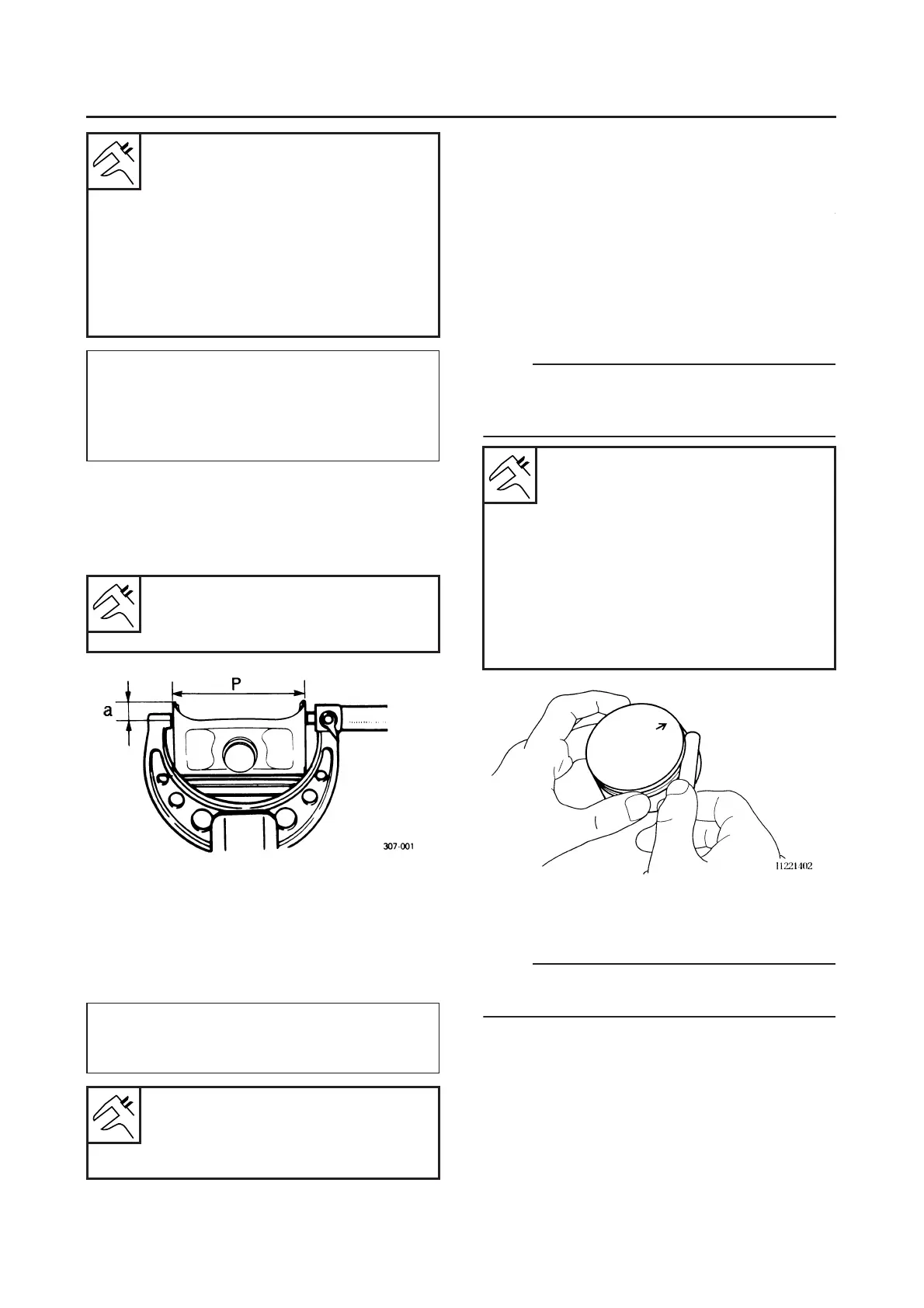

2. Install:

● Piston ring

(into the cylinder)

NOTE:

Level the piston ring into the cylinder with the

piston crown.

Bore “C”

Bore

66.000–66.010 mm

(2.5984–2.5988 in)

Taper limit “T”

Taper limit

0.050 mm (0.0020 in)

Out of round “R”

Out of round limit

0.050 mm (0.0020 in)

“C”= maximum of D1–D6

“T”= (maximum of D1 or D2)—(maximum of

D5 or D6)

“R” = maximum of D1, D3 or D5 . minimum of

D2, D4 or D6

Piston size “P”

65.965–65.980 mm

(2.5970–2.5976 in)

a. 9.0 mm (0.35 in) from the bottom edge of the pis-

ton

Piston-to-cylinder clearance =

Cylinder bore “C”

Piston skirt diameter “P”

Piston-to-cylinder clearance

0.020 – 0.045 mm (0.0008 –

0.0018 in)

Limit: 0.15 mm (0.0059 in)

Piston ring side clearance

Ring side clearance

0.030–0.065 mm (0.0012–0.0026

in)

Limit

0.100 mm (0.0039 in)

Ring side clearance

0.020–0.055 mm (0.0008–0.0022

in)

Limit

0.100 mm (0.0039 in)

Loading...

Loading...