CRANKCASE AND CRANKSHAFT

5-63

3. Check:

● Crankcase

Cracks/damage → Replace.

● Oil delivery passages

Obstruction → Blow out with compressed air.

EAS15B4207

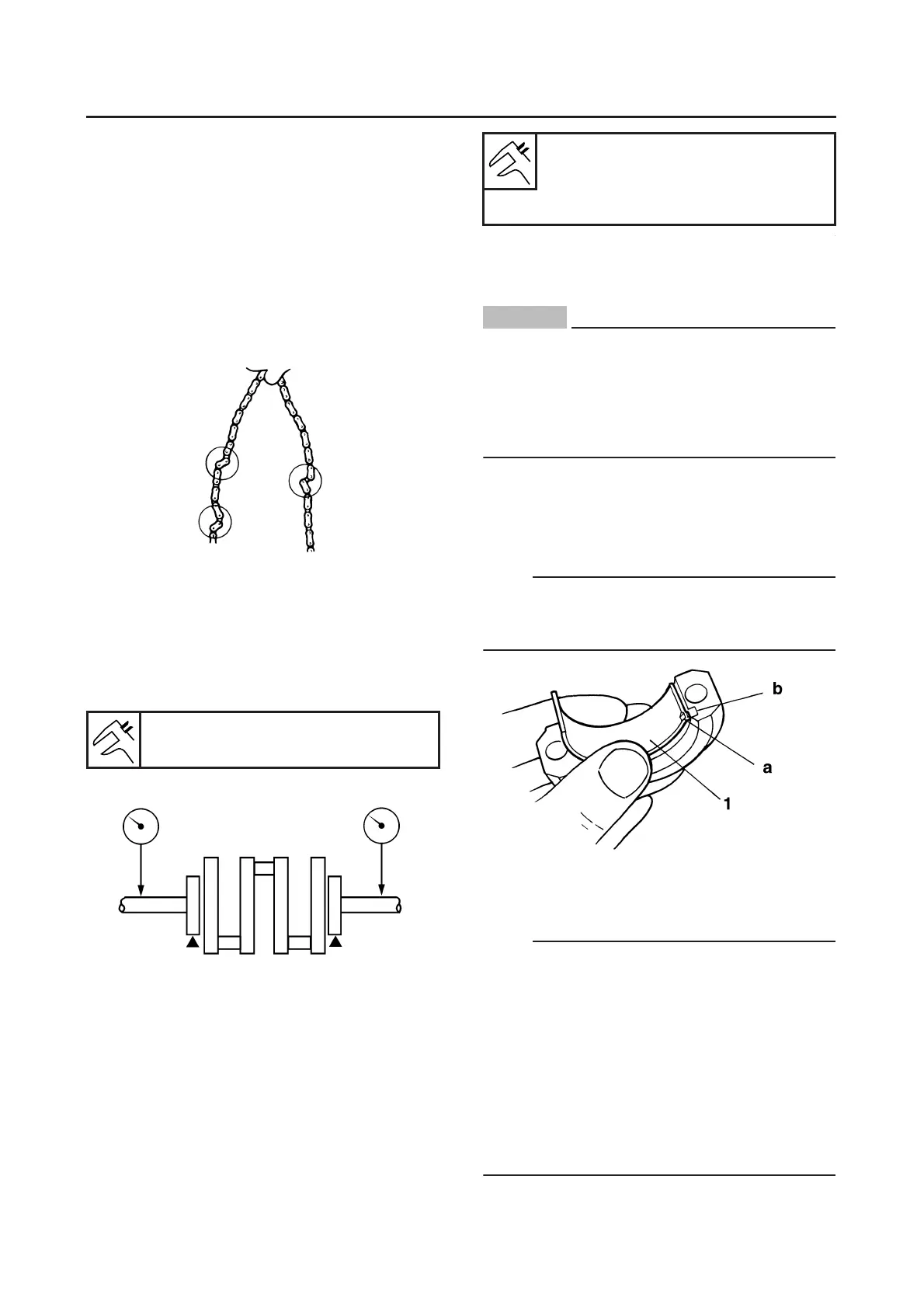

CHECKING THE TIMING CHAIN

1. Check:

● Timing chain

Damage/stiffness → Replace the timing

chain and camshaft sprockets as a set.

EAS26090

CHECKING THE CRANKSHAFT AND

CONNECTING RODS

1. Measure:

● Crankshaft runout

Out of specification → Replace the crank-

shaft.

2. Check:

● Crankshaft journal surfaces

● Crankshaft pin surfaces

● Bearing surfaces

Scratches/wear → Replace the crankshaft.

3. Measure:

● Crankshaft-pin-to-big-end-bearing clearance

Out of specification → Replace the big end

bearings.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

The following procedure applies to all of the

connecting rods.

CAUTION:

ECA13930

Do not interchange the big end bearings and

connecting rods. To obtain the correct

crankshaft-pin-to-big-end-bearing clear-

ance and prevent engine damage, the big

end bearings must be installed in their origi-

nal positions.

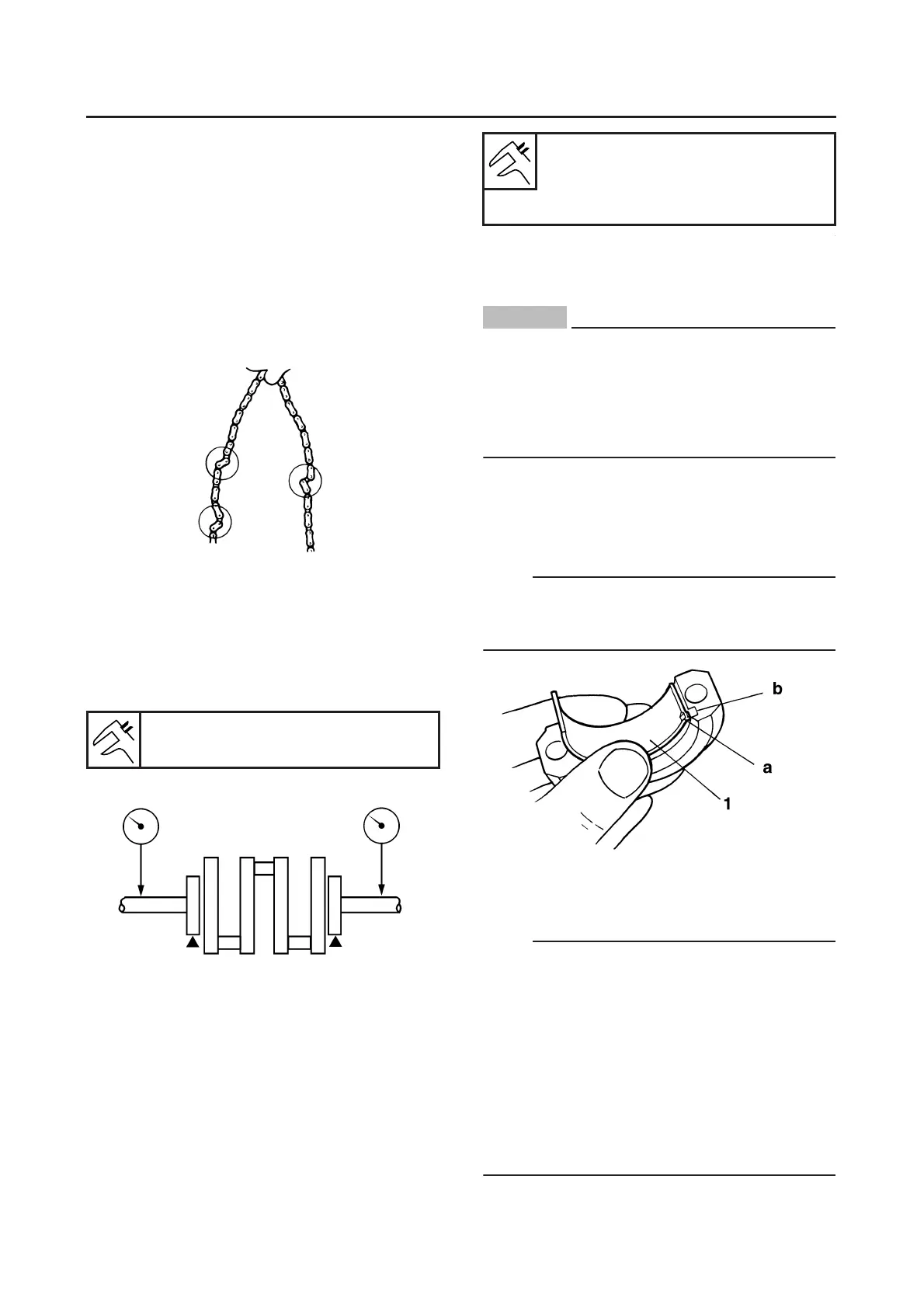

c. Clean the big end bearings, crankshaft pins,

and the inside of the connecting rod halves.

d. Install the big end upper bearing into the con-

necting rod and the big end lower bearing into

the connecting rod cap.

NOTE:

Align the projections “a” on the big end bearings

with the notches “b” in the connecting rod and

connecting rod cap.

e. Put a piece of Plastigauge® on the crank-

shaft pin.

f. Assemble the connecting rod halves.

NOTE:

● Do not move the connecting rod or crankshaft

until the clearance measurement has been

completed.

● Lubricate the bolts threads and nut seats with

molybdenum disulfide grease.

● Make sure the “Y” mark “c” on the connecting

rod faces towards the left side of the crank-

shaft.

● Make sure the characters “d” on both the con-

necting rod and connecting rod cap are

aligned.

Runout limit C

0.030 mm (0.0012 in)

Journal oil clearance (using plas-

tigauge®)

0.040–0.082 mm (0.0016–0.0032

in)

Loading...

Loading...