CRANKCASE AND CRANKSHAFT

5-68

connecting rod bolt and nut with a new one

and perform the procedure again.

CAUTION:

ECA15B1028

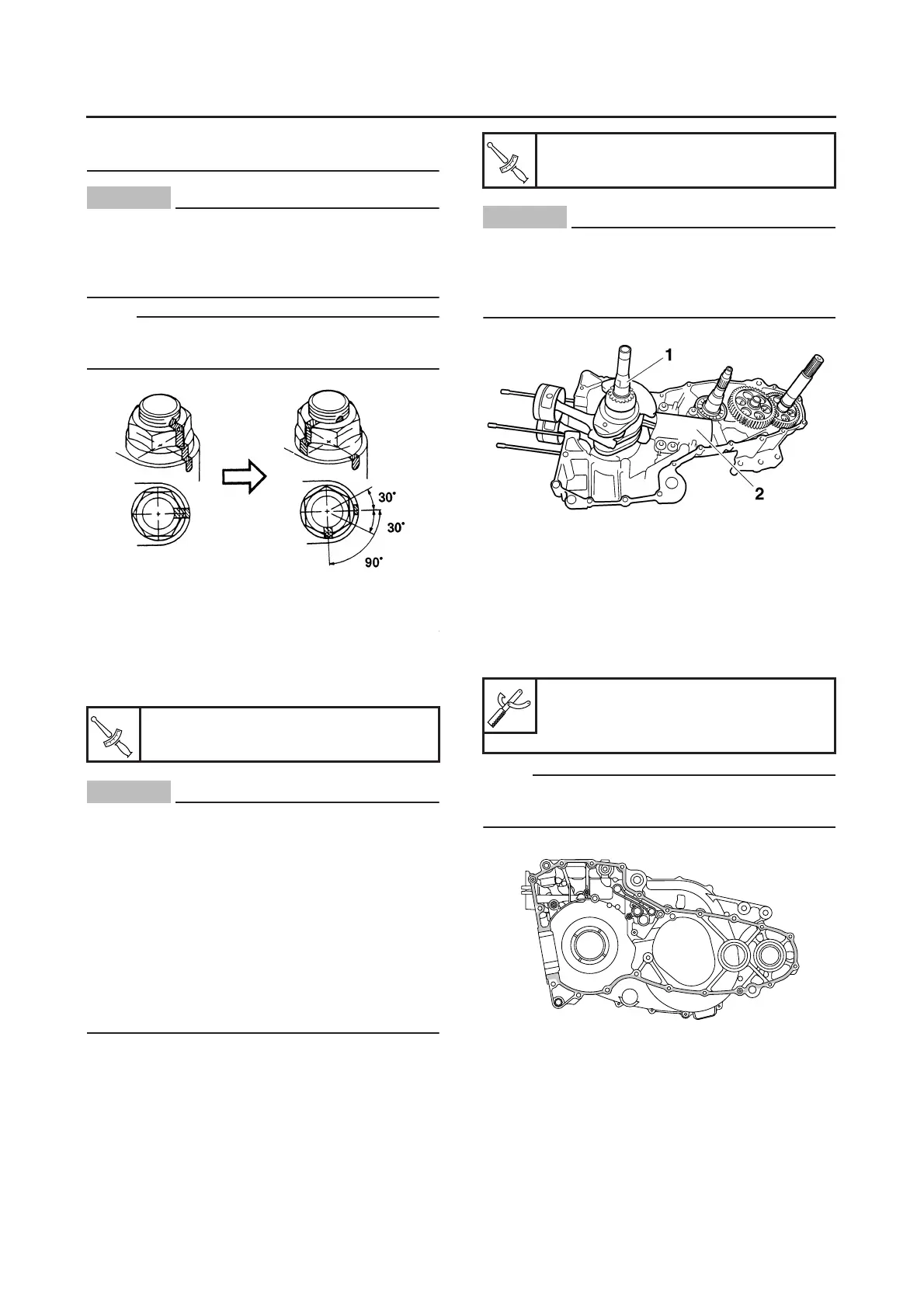

● Tighten the nut until it is at the specified an-

gles.

● Do not use a torque wrench to tighten the

connecting rod nut to the specified angle.

NOTE:

On a hexagonal nut, note that the angle from

one corner to another is 90°.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

5. Install:

● Balancer connecting rod

● Connecting rod cap

CAUTION:

ECA15B1043

● When tightening the nuts be sure to use an

F-type torque wrench.

● Without pausing, tighten to full torque

specification. Apply continuous torque

57–63 Nm (5.7–6.3 m•kg, 41–45 ft•lb). Once

you reach 57 Nm (5.7 m•kg, 41 ft•lb) DO

NOT STOP TIGHTENING until final torque is

reached. If the tightening is interrupted

57–63 Nm (5.7–6.3 m•kg, 41–45 ft•lb) loosen

the nut to less than 57 Nm (5.7 m•kg, 41

ft•lb) and start again.

EAS15B4004

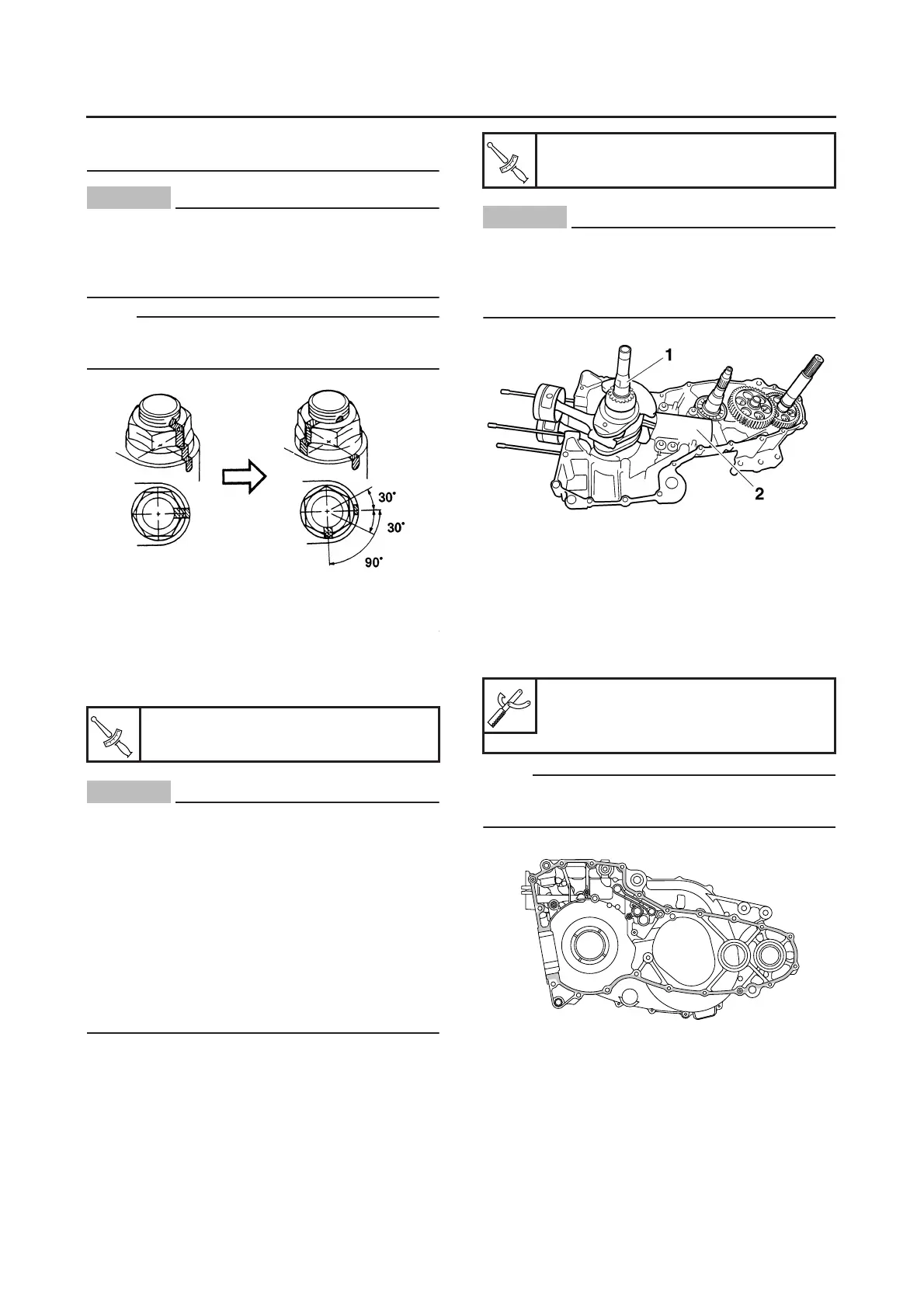

INSTALLING THE CRANKSHAFT

1. Install:

● Crankshaft assembly “1”

● Balancer piston cylinder “2”

CAUTION:

ECA15B1003

To avoid scratching the crankshaft and to

ease the installation procedure, apply grease

onto the oil seal lips and apply engine oil

onto each bearing.

EAS25700

ASSEMBLING THE CRANKCASE

1. Thoroughly clean all the gasket mating sur-

faces and crankcase mating surfaces.

2. Apply:

● Sealant

(onto the crankcase mating surfaces)

NOTE:

Do not allow any sealant to come into contact

with the oil gallery.

3. Install:

● Dowel pins

● Left crankcase

Connecting rod cap

60 Nm (6.0 m•kg, 43 ft•lb)

T

R

.

.

Balancer piston cylinder bolt

58 Nm (5.8 m•kg, 42 ft•lb)

Yamaha bond No. 1215 (Three

Bond No.1215®)

90890-85505

T

R

.

.

Loading...

Loading...