CRANKCASE AND CRANKSHAFT

5-67

EAS26150

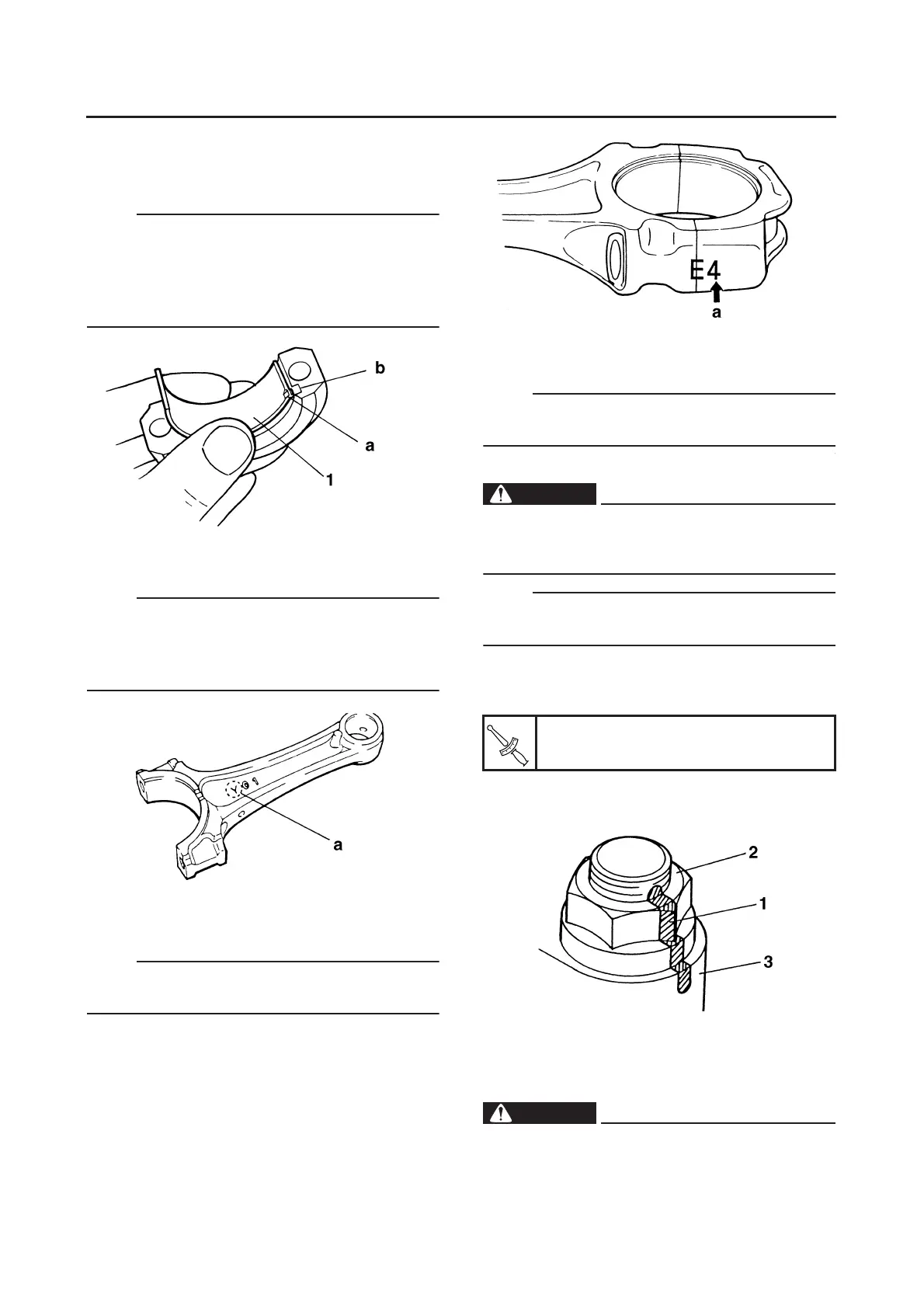

INSTALLING THE CONNECTING RODS

1. Install:

● Big end bearings “1”

NOTE:

● Align the projections “a” on the big end bear-

ings with the notches “b” in the connecting rods

and connecting rod caps.

● Be sure to reinstall each big end bearing in its

original place.

2. Install:

● Connecting rods

NOTE:

● The stamped “Y” mark “a” on the connecting

rods should face towards the left side of the

crankcase.

● Install each connecting rod in its original place.

3. Install:

● Connecting rod cap

NOTE:

Be sure that the characters “a” on the side of the

cap and connecting rod are aligned.

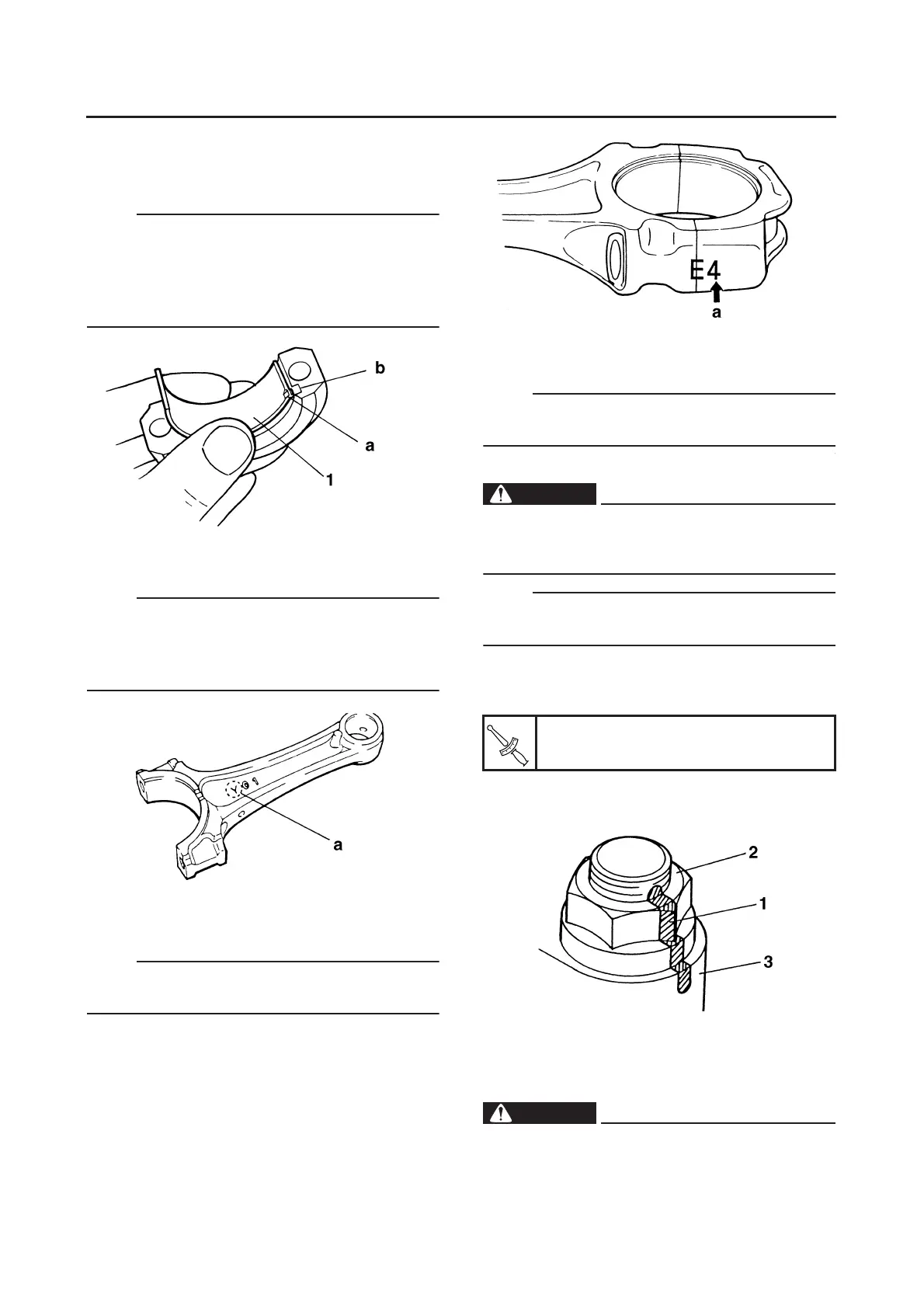

4. Tighten:

● Connecting rod nuts

NOTE:

Apply molybdenum disulfide grease to the rod

cap bolt threads and nut surfaces.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

WARNING

EWA13390

● Replace the connecting rod bolts and nuts

with new ones.

● Clean the connecting rod bolts and nuts.

NOTE:

Tighten the connecting rod bolts using the fol-

lowing procedure.

b. Clean the connecting rod bolts and nuts.

c. Tighten the connecting rod nuts with a torque

wrench.

d. Put a mark “1” on the corner of the connect-

ing rod nut “2” and the connecting rod “3”.

e. After tightening the connecting rod nut to the

specified torque, turn the connecting rod nut

clockwise another 90°.

WARNING

EWA13400

If the connecting rod nut is tightened more

than the specified angle, do not loosen the

nut and then retighten it. Instead, replace the

Connecting rod nut

16 Nm (1.6 m•kg, 11 ft•lb) + 90°

T

R

.

.

Loading...

Loading...