2-72 Phaser 7500 Printer Service Manual

Theory of Operation

Process Control

The Process Control prevents changes to the image quality due to varying

temperature and humidity in the printer, and Drum deterioration. Two process

control include: Potential Control and Toner Supply Control.

Potential Control

The Potential Control of the printer sets the charge potential (DC voltage in the

BCR), the DC component of the developing bias potential (DC voltage in the

Developer) and the exposure potential (brightness of LED in the LPH).

The charge potential (DC voltage in the BCR) and the developing bias potential

are calculated based on the temperature and humidity in the printer, which are

measured by the Environment Sensor.

The exposure potential is calculated based on the temperature and humidity in

the printer, which are measured by the Environment Sensor, and the patch density

on the belt, which is read by the ADC Sensor.

The patch is a small image for Process Control that is created on the belt.

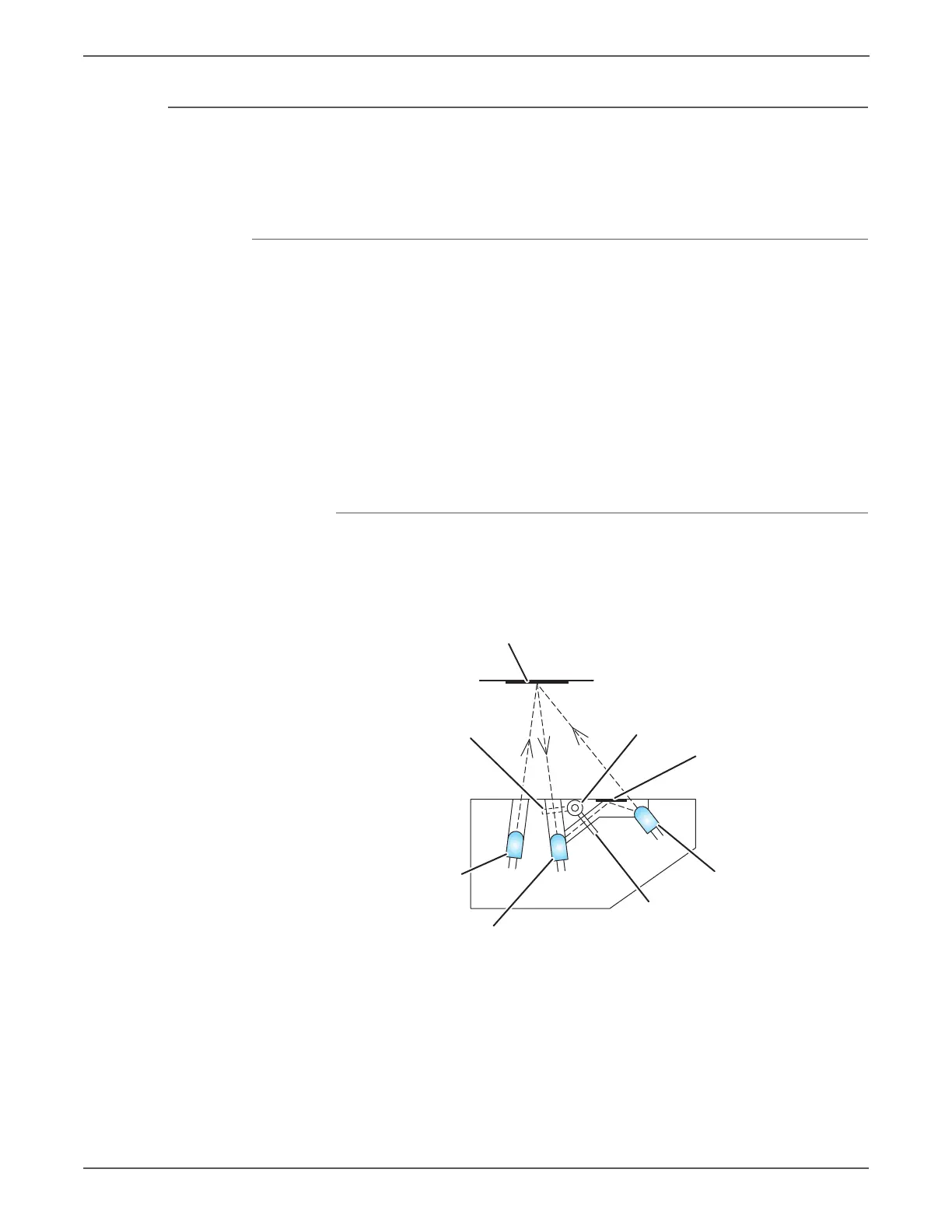

ADC Sensor

Using two LEDs for Black and Color, the ADC Sensor reads the patch density of

each of the two reflection paths, which have different light axis angles. The LED for

Black uses a mirror reflection light path and the LED for Color uses a diffused

reflection light path.

s7500-423

Belt

Position at Shutter (Closed)

(Reference Board Detection)

Reference Board Light

Path Switching Component

Built-in

Reference Board

Diffused Reflection

LED (for YMC)

Straight Reflection

LED (for K)

Common Receptor Element

Position at Shutter (Open)

(Reference Board Detection)

Loading...

Loading...