Phaser 7500 Printer Service Manual 2-17

Theory of Operation

Electric Discharge

The charge on the paper is neutralized/removed by the Detack Saw (serrated

metal plate) to peel off the paper from the belt.

• The Detack Saw is a serrated metal plate with an acute edge that is connected

to the frame ground.

• The Detack Saw is close to the back of the paper. If the charge that was

applied to the paper in the "Secondary Transfer" process gets discharged

unevenly to the chutes and other metallic parts before the fusing, it will cause

image distortion and toner dispersion. To prevent this, the positive charge that

was applied to the paper is actively discharged by the Detack Saw so as to

evenly neutralize/remove it.

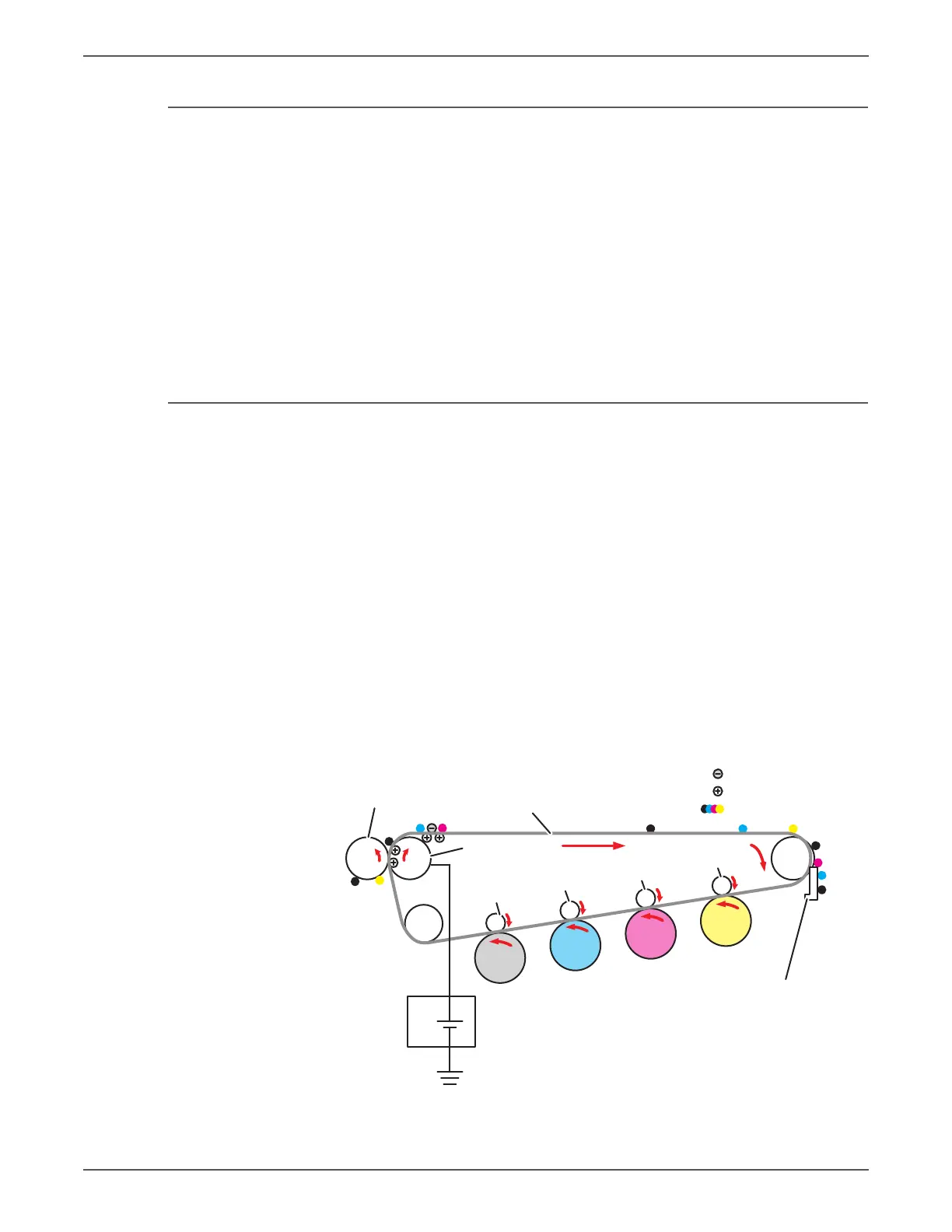

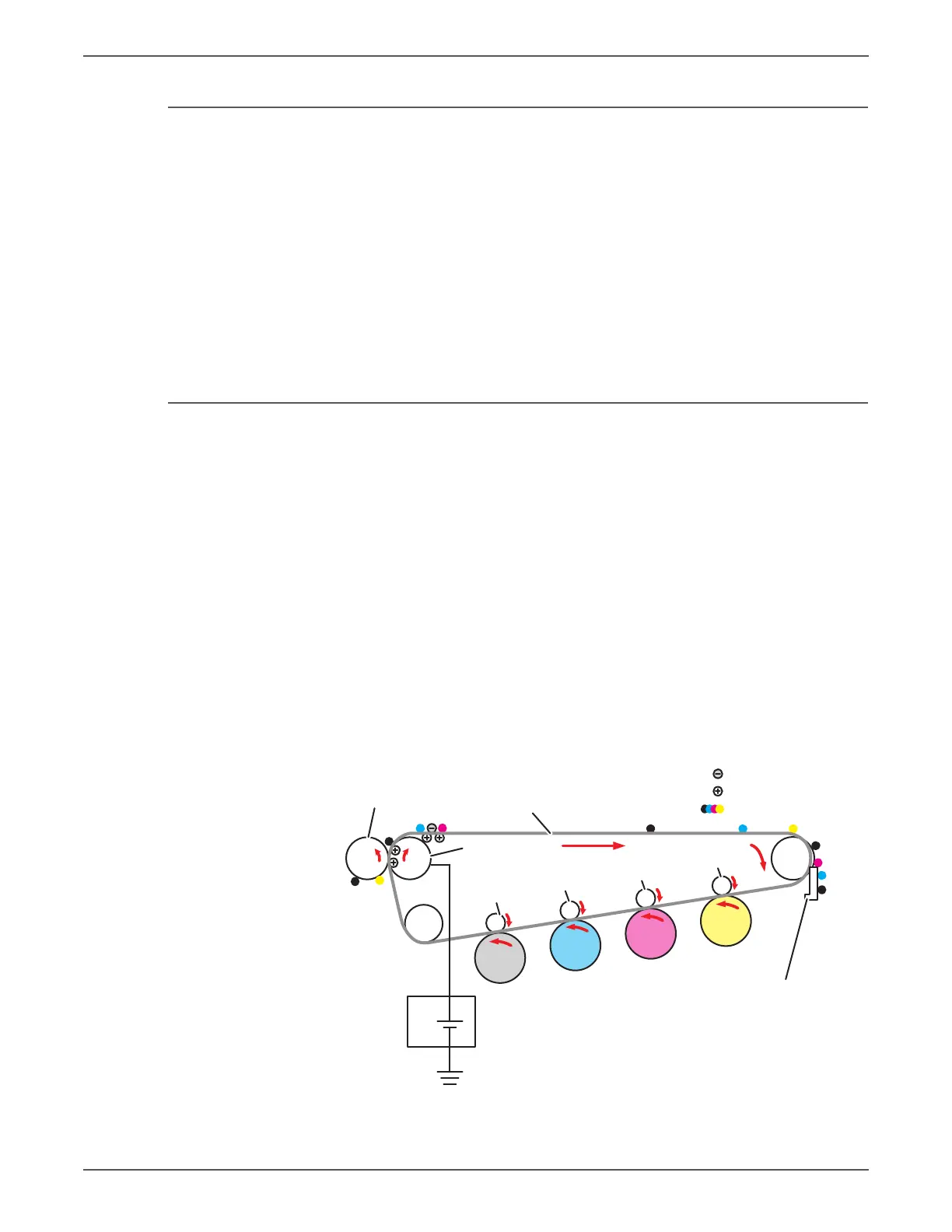

Cleaning (Belt/ 2nd BTR)

The non-transferred toner on the belt and the unwanted toner that is stuck to the

2nd BTR are removed after the toner image has been transferred to the paper.

• Cleaning the Belt - Toner that was not transferred to the paper during the

"Secondary Transfer" process remains on the belt surface. Because this toner

will interfere with the subsequent processes if allowed to remain on the belt

surface, the Cleaning Blade that is in contact with the belt scrapes off the

remaining toner, which is then transported by the Belt Waste Toner Collector

into the Waste Cartridge.

• Cleaning the 2nd BTR - Unwanted toner that adhered to the 2nd BTR during

the "Secondary Transfer" process will dirty the back side of subsequent paper.

To prevent this, positive DC Voltage from the HVPS is applied to the Backup

Roll that faces the 2nd BTR to transfer the toner on the 2nd BTR back to the

belt. The Cleaning Blade that is in contact with the belt then scrapes off the

toner that was transferred back to the belt, which is then transported by the

Belt Waste Toner Collector into the Waste Cartridge.

s7500-352

2nd BTR

Belt

: Negative Charge

: Positive Charge

: Toner

Cleaning Roll

Backup Roller

1st BTR (K)

1st BTR (C)

1st BTR (M)

1st BTR (Y)

Drum (K)

Drum (C)

Drum (M)

Drum (Y)

HVPS

Loading...

Loading...