20

OilLevelSensorGASOLINEVEHICLE-ENGINE

532

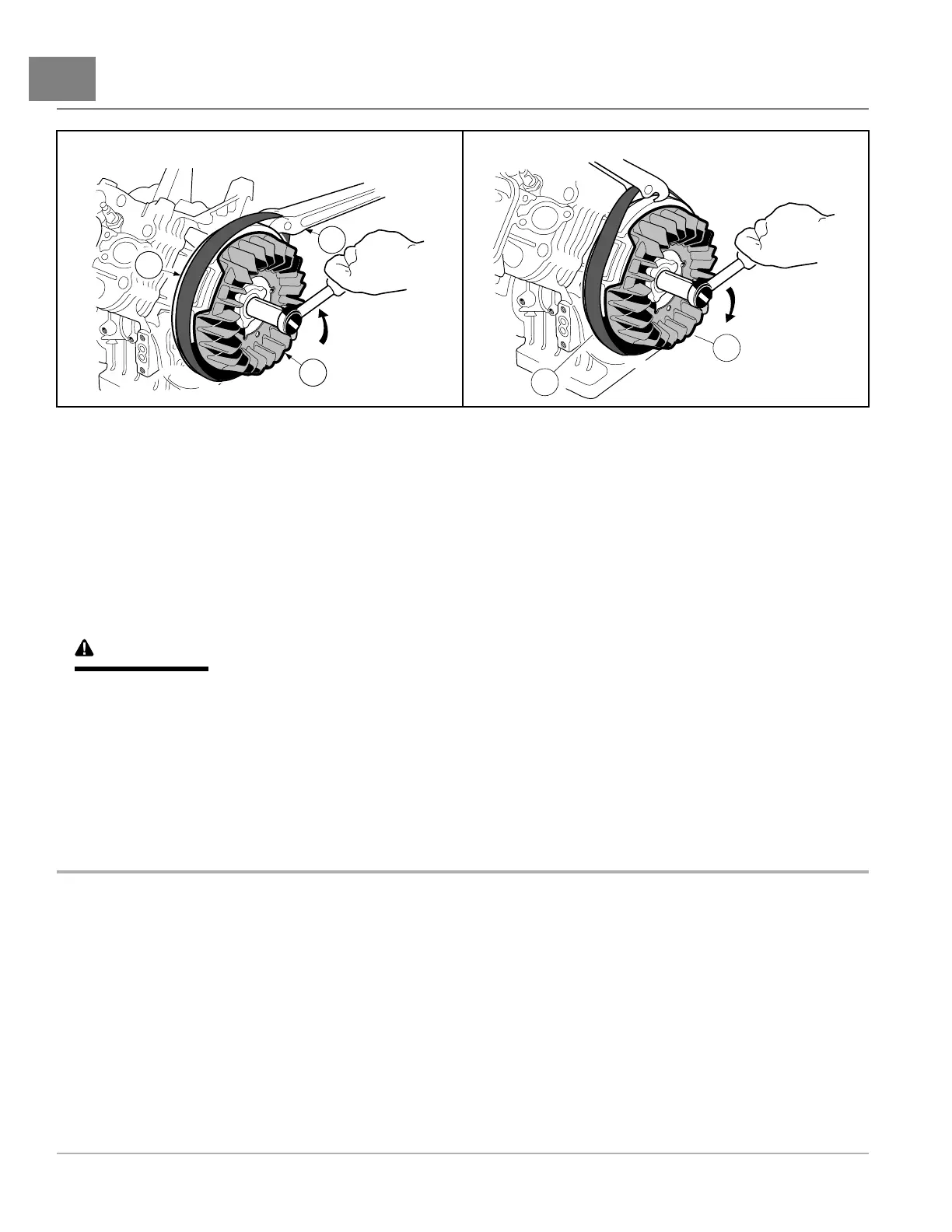

Figure20-9FlywheelNutRemoval

533

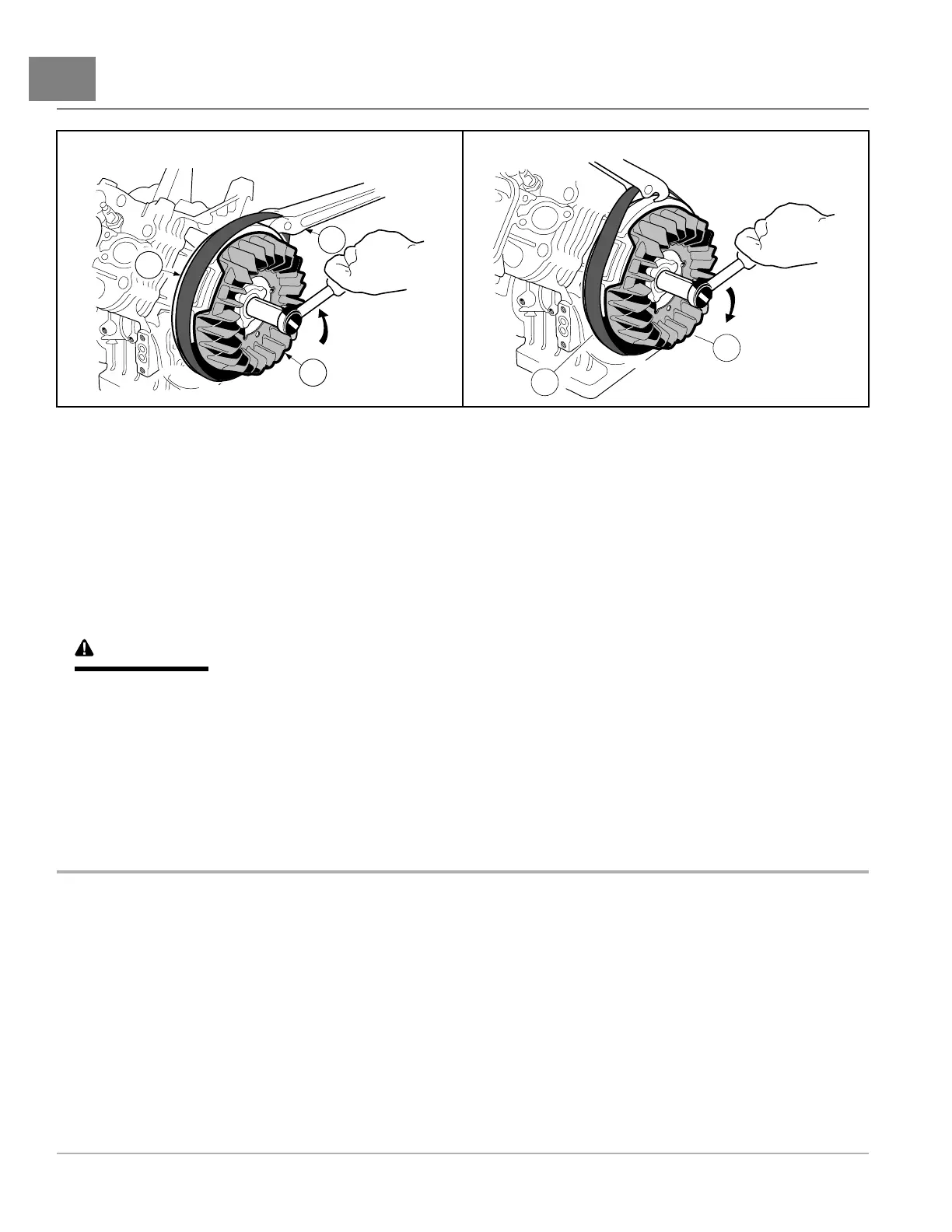

Figure20-10FanandFlywheelInstallation

FLYWHEELINSTALLATION

1.Wipeoffanyoilontaperedportionsofcrankshaftandywheel(4)(Figure20-8,Page20-11).

2.Insertwoodruffkey(10)intokeywayofcrankshaft.Thenaligngrooveinywheel(4)towoodruffkey(10)and

pushywheelontocrankshaftuntilitseats.Installandfan(7),atwasher(9),andnut(8)nger-tight.

3.Useastrapwrench(3)tokeepywheelandfanassembly(1)fromturningwhiletighteningywheelnutto80

ft·lb(110N·m)(Figure20-10,Page20-12).SeefollowingCAUTION.

CAUTION

•Theywheelnuthasright-handthreads.Turnitclockwisetotighten,orcounterclockwisetoloosen.

•Becarefulnottodamagethefanblades.Useastrapwrenchtoholdywheel.Donotplacescrewdriver

orprybarbetweenfanblades.

4.Installfanhousing(2)andtightenscrews(1)to90in·lb(10N·m)(Figure20-8,Page20-11).

OILLEVELSENSOR

TESTINGTHEOILLEVELSENSOR

SeeOilLevelSensoronpage18-31.

OILLEVELSENSORREMOVAL

1.Drainoilfromengine.SeeEngineOil–GasolineVehicle,Section20,Page20-2.

2.Removeywheel.SeeFlywheelRemovalonpage20-11.

3.Removebolt(1)securingoilsensorwireclamp(2)toengine.

4.Disconnectoillevelsensorwire(3)fromwireharness(Figure20-11,Page20-13).

5.Removetwobolts(4)securingoilsensor(5)inengine.

Page20-122019PrecedentVillager2MaintenanceandServiceManual

Loading...

Loading...