7

FrontSuspensionComponentsSTEERINGANDFRONTSUSPENSION

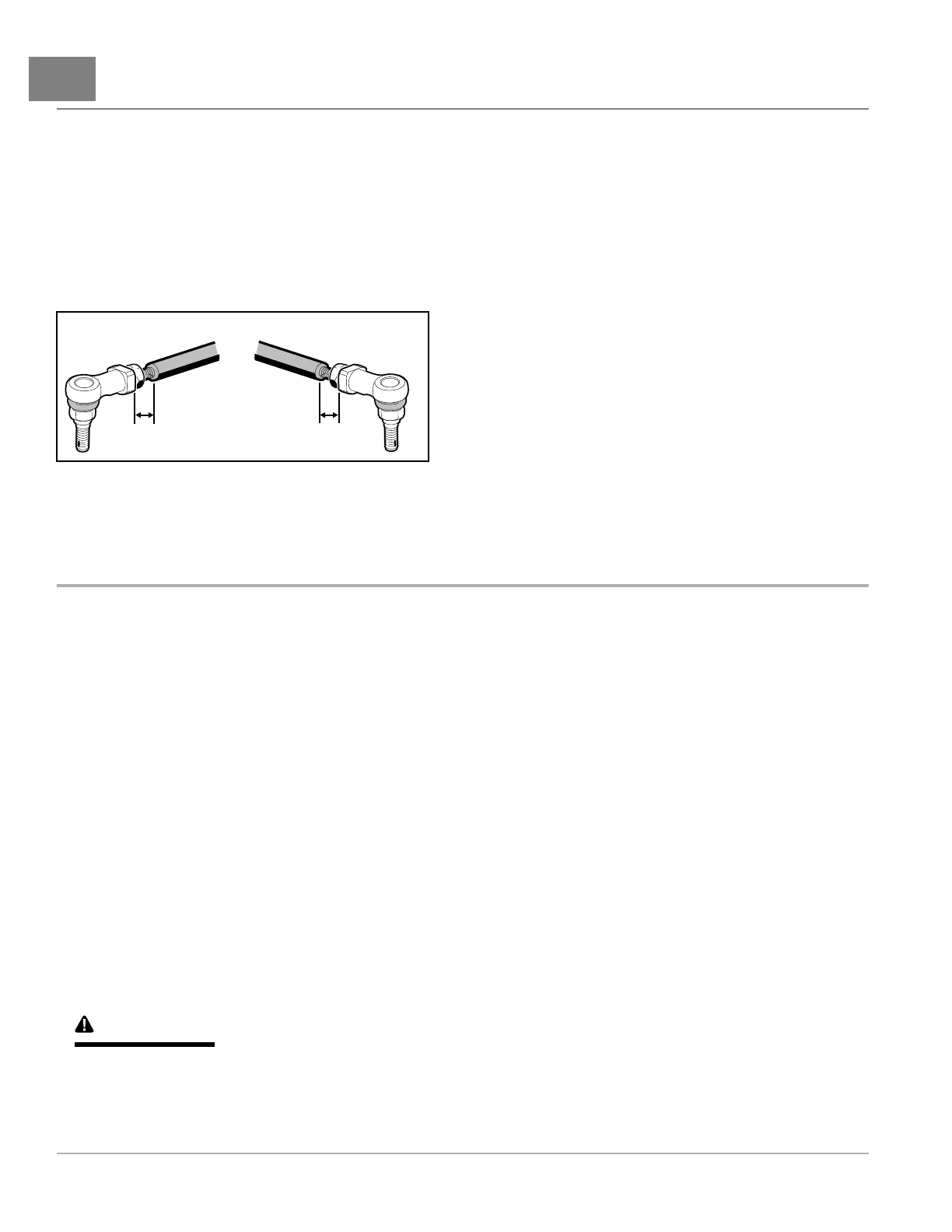

6.1.Loosenthejamnutsonbothendsofeachdraglink(Figure7-8,Page7-7).

6.2.Rotatebothofthedraglinksequally.T oincreasethetoe-in,rotatebothdraglinkscounterclockwise.To

decreasethetoe-in,rotatebothdraglinksclockwise.Maintainanequaldistancefromtheballjointtothe

endofthethreadsoneachdraglink(Figure7-9,Page7-8).

6.3.Tightenjamnutsto26ft·lb(35N·m).

6.4.Checkthetoe-in,andrepeattheadjustmentprocedureifnecessary.

6.5.Aftertoe-inadjustmentismadeandwithwheelsinthestraightaheadposition,thesteeringwheelshouldbe

atthecenterofitstravel.Thereshouldbeequaltraveltotheleftandright.

2064

Figure7-9AdjustBothDragLinksToAnEqualDistance

FRONTSUSPENSIONCOMPONENTS

SeeGeneralWarningsonpage1-2.

TIERODENDREMOVAL

1.ElectricVehicle:Disconnectthebatteriesanddischargethecontroller.SeeDisconnectingtheBatteries–

ElectricVehiclesonpage1-4.

GasolineVehicle:Disconnectbatteryandsparkplugwire(s).

SeeDisconnectingtheBattery-GasolineVehiclesonpage1-3.

2.Loosenjamnuts(13)toallowlaterrotationofthetierodends(12)(Figure7-10,Page7-12).

3.Removetheretainingnuts(14).

4.Liftmalethreadoftierodfromtheholeinthespindletab.

5.Removethetierodendsfromthesteeringgear.

6.Tominimizecorrosion,applyalightcoatofanti-seizelubricatingcompoundtothethreadswherethetierod

endsareinstalled.

TIERODINSTALLATION

1.Threadtierodends(12)ontosteeringgeartoadepthof1/2inch(12.5mm)(Figure7-10,Page7-12).

WARNING

•Thetierodendsmustbethreadedintotherodatleast5/16ofaninch(8mm).Failuretothreaddeep

enoughmaycausetierodendstoseparatefromtherodduringadjustmentorwhilebeingoperated,

possiblyresultinginlossofvehiclecontrolandseverepersonalinjury.

2.Installtierodends(12)intothespindletabs.Installtheretainingnuts(14)(Figure7-10,Page7-12).

Page7-82019PrecedentVillager2MaintenanceandServiceManual

Loading...

Loading...