GASOLINEVEHICLE-CLUTCHESDrivenClutch

23

608

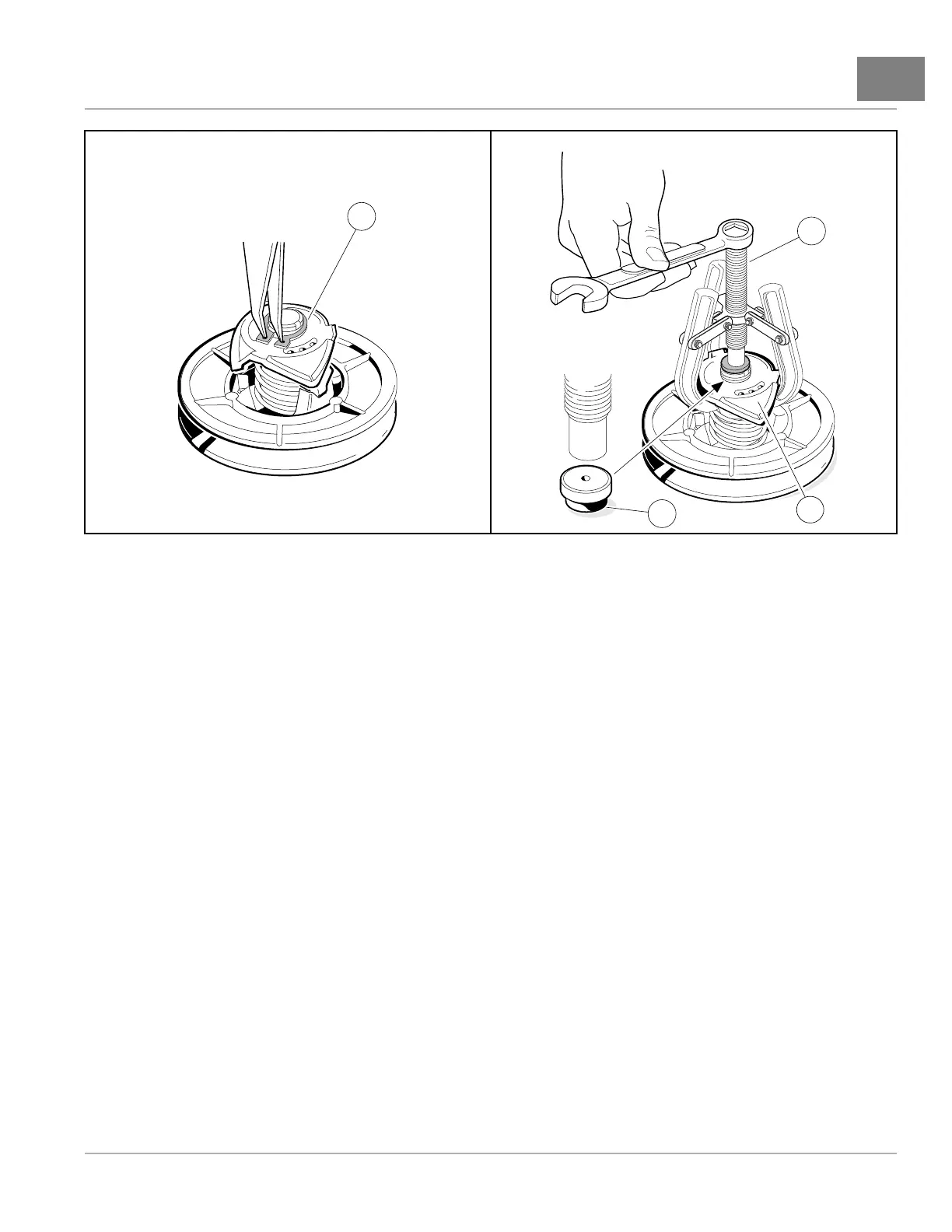

Figure23-15RemoveRetainingRing

609

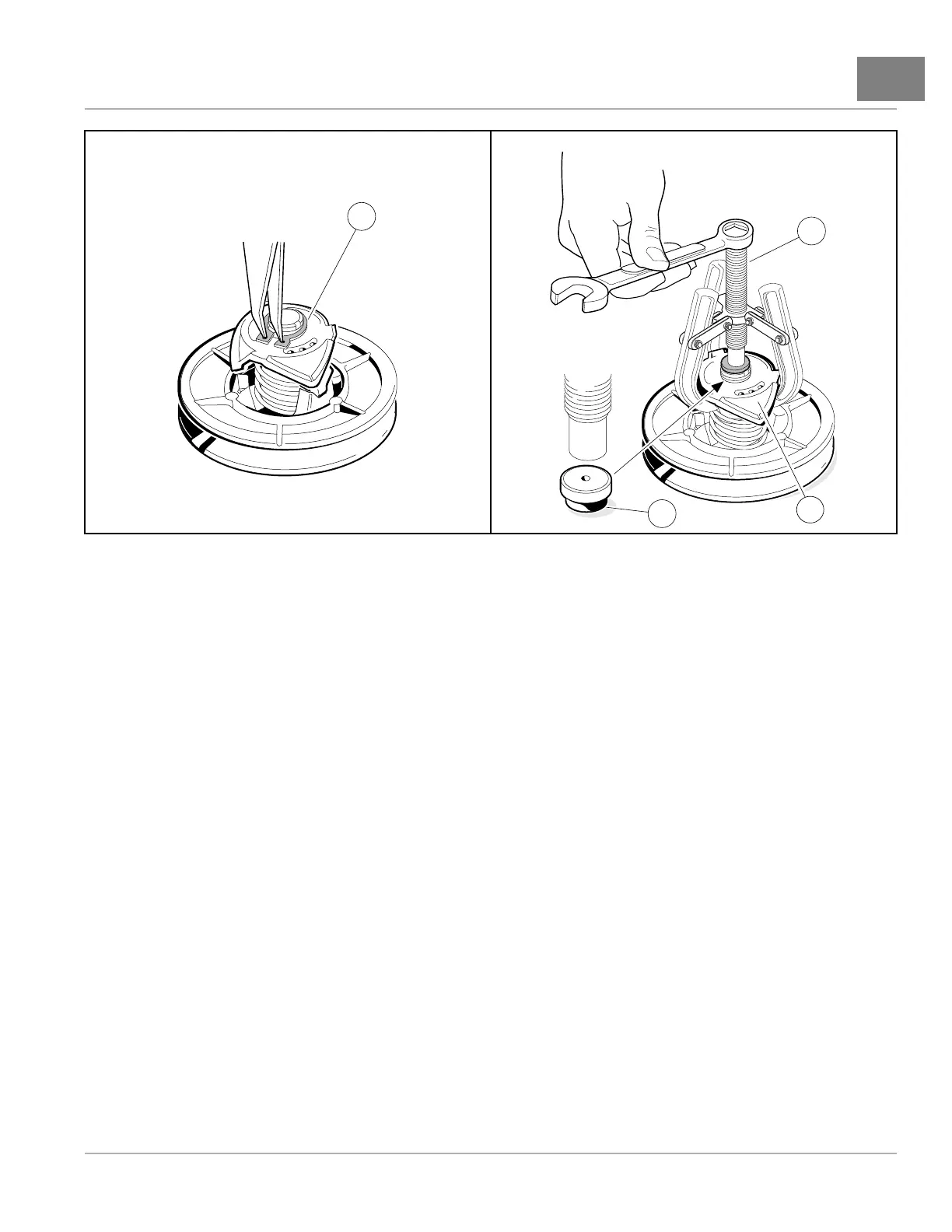

Figure23-16DrivenClutchDisassembly

DRIVENCLUTCHINSPECTION

1.Inspectthecam(5)forexcessivewear(Figure23-14,Page23-13).Replaceitifnecessary.

2.Inspectthedrivebuttons(8)forexcessivewear.Replaceifnecessary.Toremovethedrivebuttons(8),remove

thesocket-headcapscrews(7)andthenthebuttons.

3.Inspectthesmoothsurfaceonthexedandmoveablesheaves.Sheavesmustbereplacedifsurfacesareworn

morethan0.060in.(1.5mm).

4.Inspectthebronzebearinginthemoveablesheave.Ifthebearingborediameterismorethan1.384in.(35.15

mm),theentiremoveablesheavemustbereplaced.

5.Inspecttheshaftofthexedsheave.Thereshouldbenonoticeablewear.Replacethexedsheaveifitis

worn,scratchedordamaged.

DRIVENCLUTCHASSEMBLY

1.Placethethreedrivebuttons(8)inposition.ApplyonedropofLoctite

®

222toeachofthesocket-headcap

screws(7)andtheninstallandtightenthemto8in·lb(0.9N·m)(Figure23-14,Page23-13).

2.Slidetheacetalwasher(10)andmoveablesheave(9)ontothexedsheave(11).

3.Placetheendofthespring(6)intotheholeinthemoveablesheave(9).

4.Installthekey(4)intothekeywayofthexedsheave(11)shaft.

5.Holdingthecam(5)inpositionforassemblyontheshaft,installtheotherendofthespring(6)intothecenter

springholeofthecam.Rotatethecamuntilthekeywayisalignedwiththekey(4)onthexedsheave,andthen

startthecamontotheshaftapproximately1/4to3/8in.(6.3to9.5mm).

5.1.PressAssemblyProcess:

5.1.1.Placetheclutchassemblyinapressandpositionthecampresstoolonthecam(2)asshown

(Figure23-17,Page23-16).

2019PrecedentVillager2MaintenanceandServiceManualPage23-15

Loading...

Loading...