1D-36 Engine Mechanical:

Valve Clearance Inspection and Adjustment

B718H11406008

Refer to “Valve Clearance Inspection and Adjustment in

Section 0B (Page 0B-5)”.

Camshaft Inspection

B718H11406009

Refer to “Engine Top Side Disassembly (Page 1D-24)”.

Refer to “Engine Top Side Assembly (Page 1D-28)”.

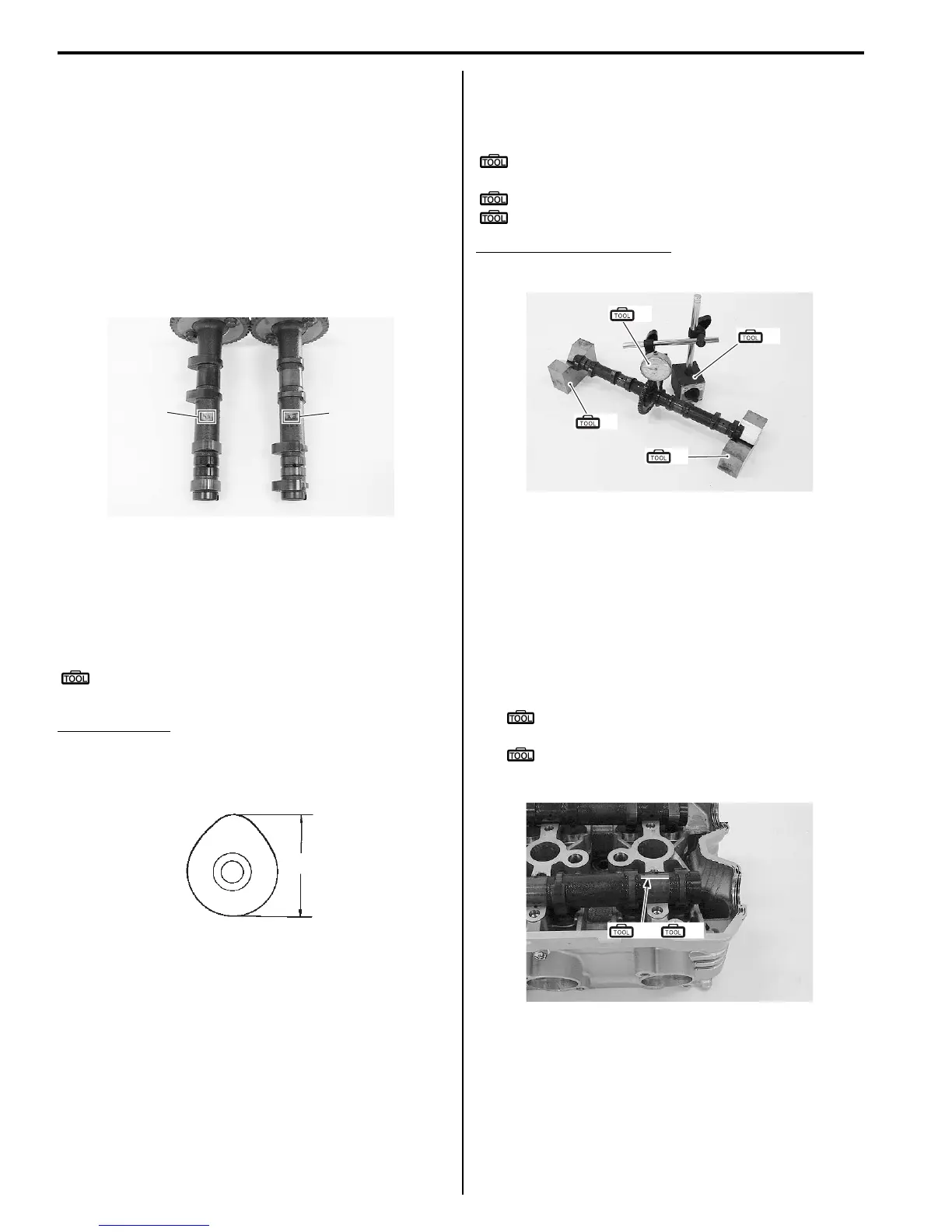

Camshaft Identification

The exhaust camshaft has the embossed letters “EX”

and the intake camshaft has the embossed letters “IN”.

Cam Wear

Check the camshaft for wear or damage.

Measure the cam height “a” with a micrometer.

Replace a camshaft if the cams are worn to the service

limit.

Special tool

: 09900–20202 (Micrometer (1/100 mm, 25 – 50

mm))

Cam height “a”

Service limit: (IN) 34.98 mm (1.377 in)

Service limit: (EX) 33.88 mm (1.334 in)

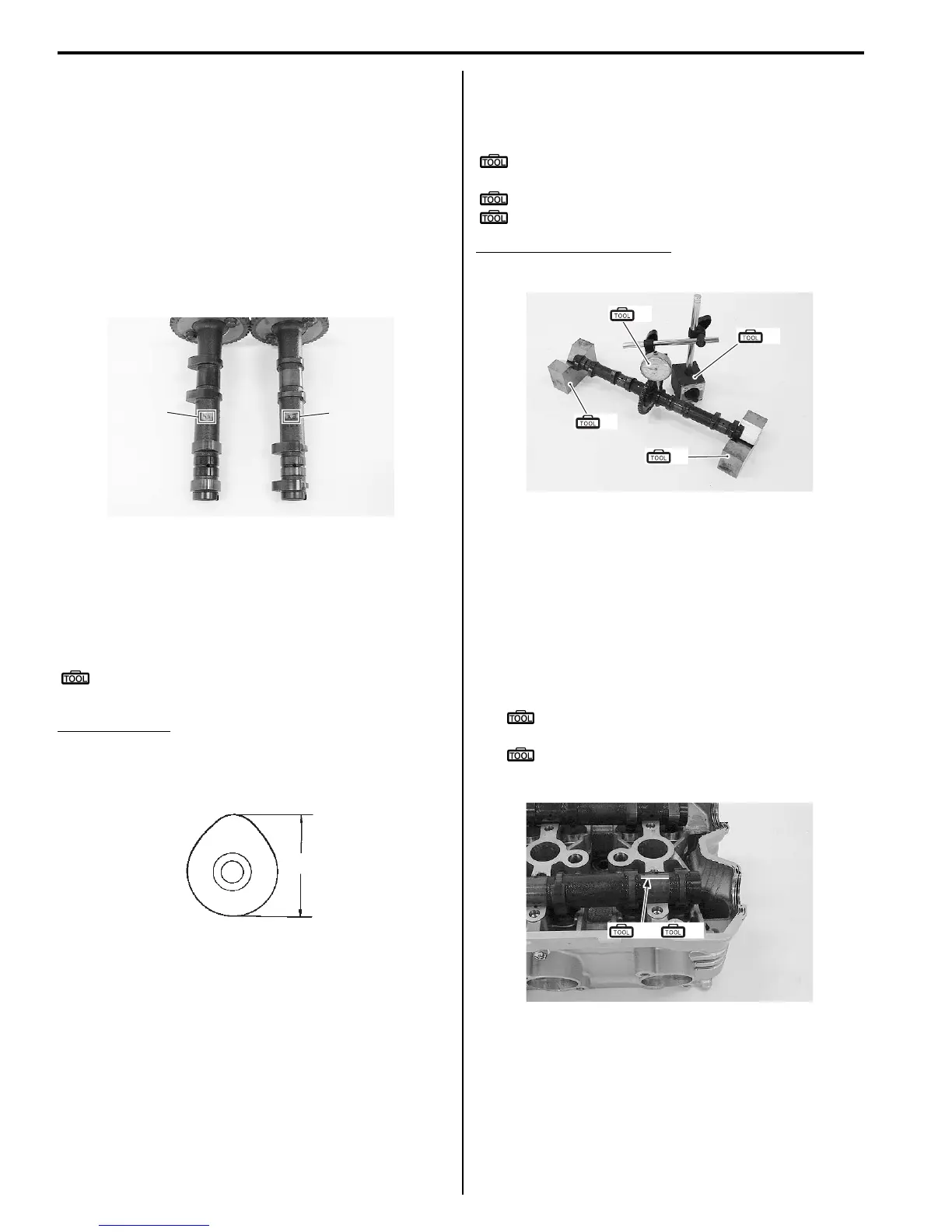

Camshaft Runout

Measure the runout using the dial gauge. Replace the

camshaft if the runout exceeds the limit.

Special tool

(A): 09900–20607 (Dial gauge (1/100 mm, 10

mm))

(B): 09900–20701 (Magnetic stand)

(C): 09900–21304 (V-block (100 mm))

Camshaft runout (IN & EX)

Service limit: 0.10 mm (0.004 in)

Camshaft Journal Wear

Inspect the camshaft journal wear in the following

procedures:

1) Determine whether or not each journal is worn down

to the limit by measuring the oil clearance with the

camshaft installed in place.

2) Use the plastigauge to read the clearance at the

widest portion, which is specified as follows.

Special tool

(A): 09900–22301 (Plastigauge (0.025 -

0.076 mm))

(B): 09900–22302 (Plastigauge (0.051 -

0.152 mm))

EX

IN

I718H1140081-01

“a”

I649G1140199-02

(A)

(B)

(C)

(C)

I718H1140082-01

(A) (B)

/

I718H1140083-03

Loading...

Loading...