1D-74 Engine Mechanical:

Balancer Shaft

Inspect the balancer shaft for wear or damage. Replace

the balancer shaft if there is anything unusual.

Conrod Removal and Installation

B718H11406026

Removal

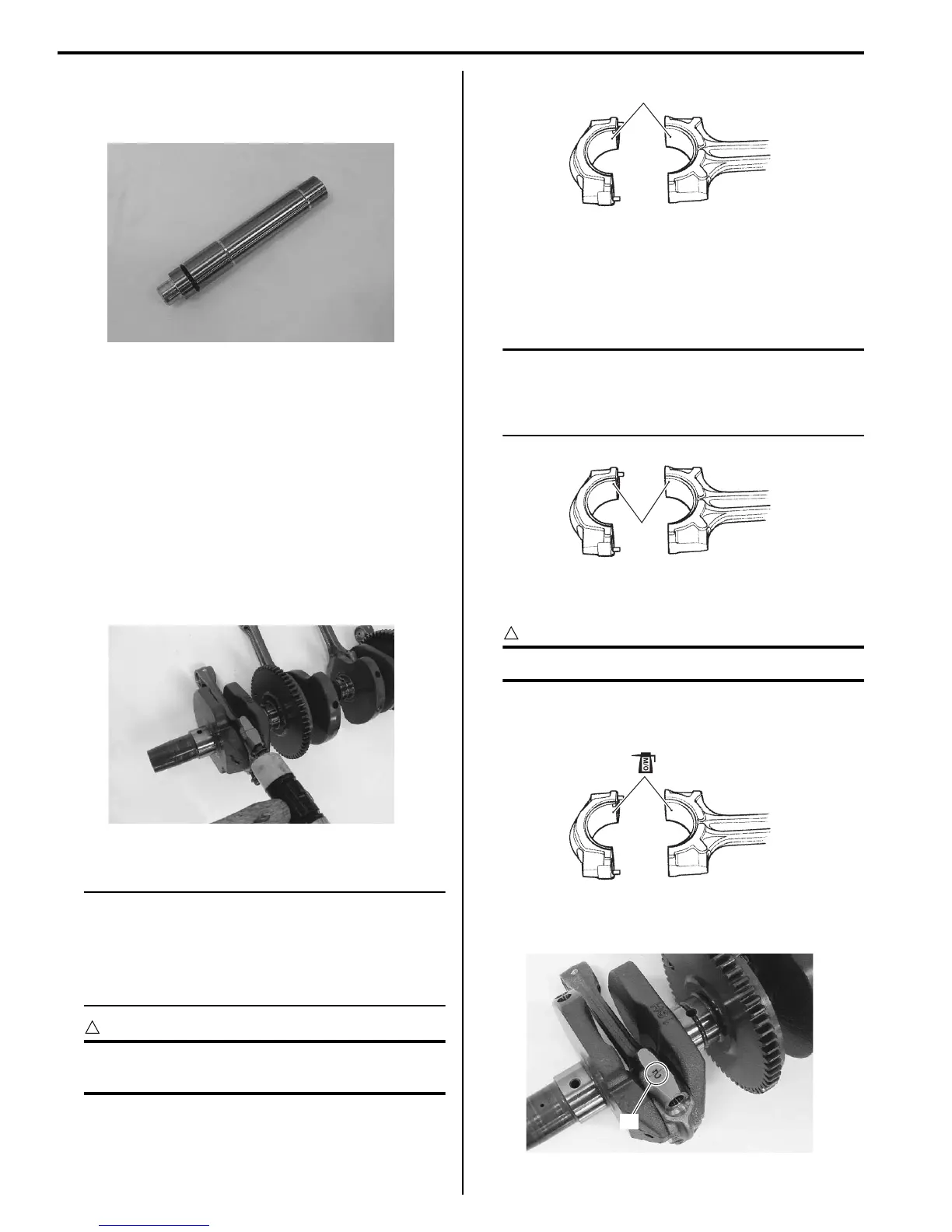

1) Remove the crankshaft assembly from the

crankcase. Refer to “Engine Bottom Side

Disassembly (Page 1D-53)”.

2) Loosen the conrod cap bolts by using a 10 mm, 12

point socket wrench, and tap the conrod cap bolts

lightly with plastic hammer to remove the conrod

cap.

3) Remove the conrods and mark them to identify their

respective cylinders.

4) Remove the bearings (1).

NOTE

• Do not remove the bearings (1) unless

absolutely necessary.

• Make a note of where the bearings are

removed from so that they can be

reinstalled in their original positions.

CAUTION

!

When removing the bearings, be careful not

to scratch the conrods and the bearings.

Installation

1) When installing the bearings into the conrod cap and

conrod, be sure to install the tab “A” first, and then

press in the opposite side of the bearing.

NOTE

Inspect and select the conrod crank pin

bearing if necessary. Refer to “Conrod Crank

Pin Bearing Inspection and Selection

(Page 1D-76)”.

2) Apply molybdenum oil solution to the crank pin and

bearing surface.

CAUTION

!

Be sure to clean the conrod big end.

M/O: Molybdenum oil (Molybdenum oil

solution)

3) When fitting the conrod cap, make sure that I.D.

code “B” on each conrod faces intake side.

I718H1140267-01

I718H1140268-01

1

I718H1140269-01

“A”

I718H1140272-01

I718H1140273-01

“B”

I718H1140274-01

Loading...

Loading...