Engine Mechanical: 1D-75

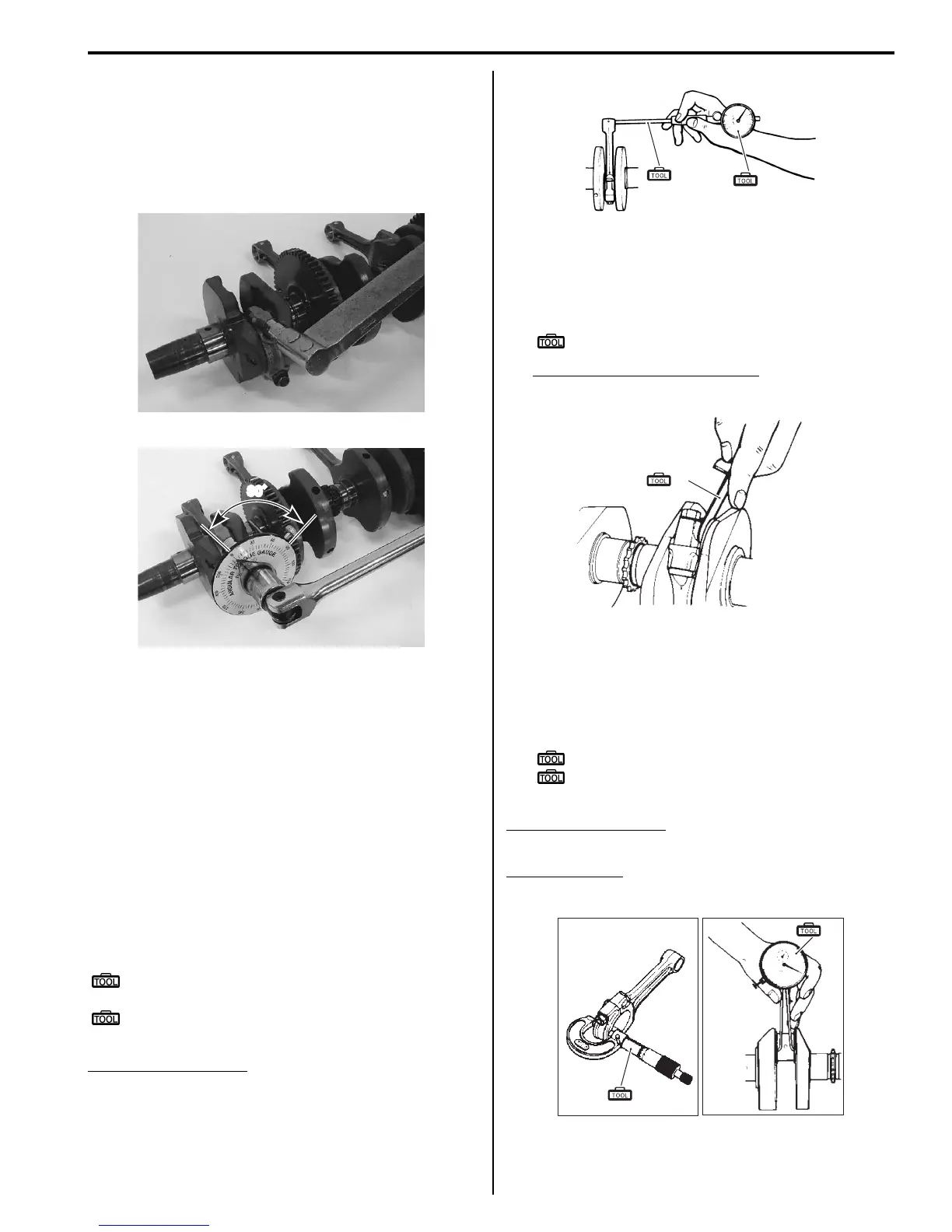

4) Apply engine oil to the conrod cap bolts.

5) Tighten the conrod cap bolt by using a 10 mm, 12

point socket wrench in the following two steps.

Tightening torque

Conrod cap bolt: 21 N⋅m (2.1 kgf-m, 15.0 Ib-ft)

then turn in 1/4 (90°) turn.

6) Check that the conrod moves smoothly.

7) Install the crankshaft assembly to the crankcase.

Refer to “Engine Bottom Side Assembly (Page 1D-

61)”.

Conrod and Crankshaft Inspection

B718H11406027

Refer to “Conrod Removal and Installation (Page 1D-

74)”.

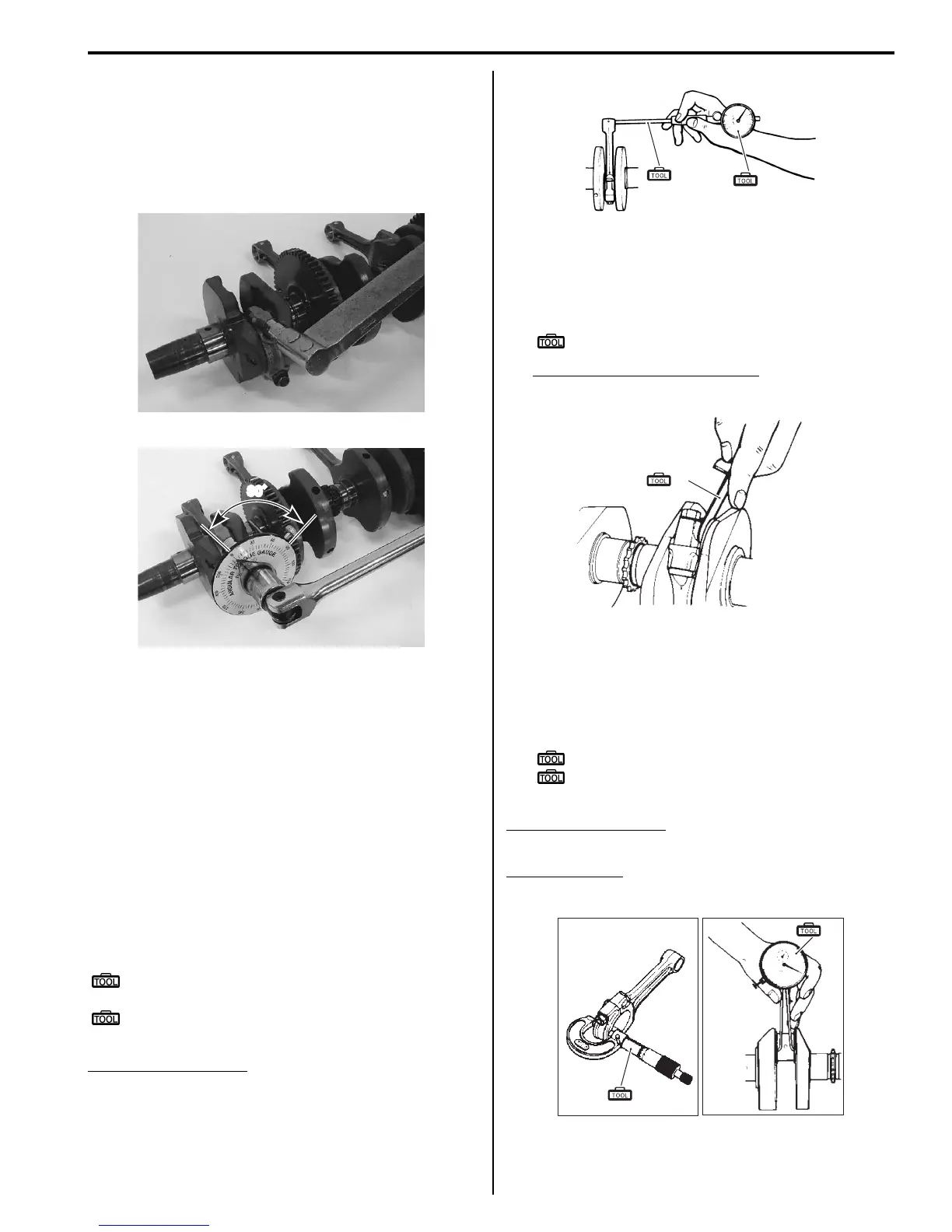

Conrod Small End I.D.

Measure the conrod small end inside diameter using the

small bore gauge.

If the conrod small end inside diameter exceeds the

service limit, replace the conrod.

Special tool

(A): 09900–20602 (Dial gauge (1/1000 mm, 1

mm))

(B): 09900–22403 (Small bore gauge (18 – 35

mm))

Conrod small end I.D.

Service limit: 18.040 mm (0.7102 in)

Conrod Big End Side Clearance

1) Check the conrod big end side clearance using the

thickness gauge.

Special tool

(A): 09900–20803 (Thickness gauge)

Conrod big end side clearance

Service limit: 0.3 mm (0.012 in)

2) If the clearance exceeds the limit, remove the conrod

and measure the conrod big end width and crank pin

width. Refer to “Conrod Removal and Installation

(Page 1D-74)”. If any of the measurements are out

of specification, replace the conrod or crankshaft.

Special tool

(B): 09900–20205 (Micrometer (0 – 25 mm))

(C): 09900–20605 (Dial calipers (1/100 mm,

10 - 34 mm))

Conrod big end width

Standard: 20.95 – 21.00 mm (0.825 – 0.827 in)

Crank pin width

Standard: 21.10 – 21.15 mm (0.831 – 0.833 in)

I718H1140275-01

90˚

I718H1140279-01

(B)

(A)

I718H1140280-01

(A)

I718H1140281-01

(B)

(C)

I718H1140282-01

Loading...

Loading...