4 - 16

Inspection and

Adjustment

Inspection and

Adjustment

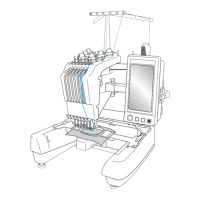

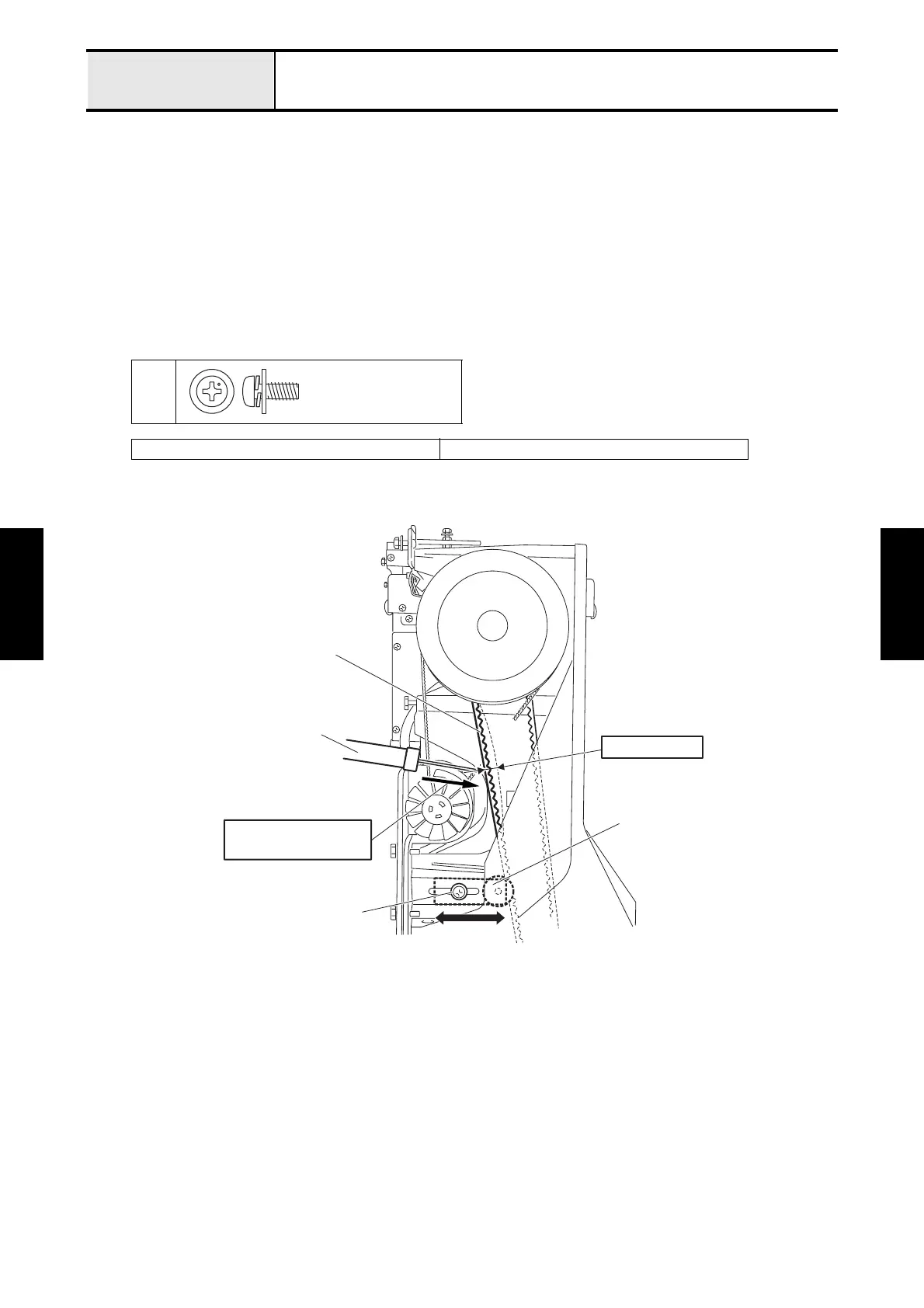

Adjustment Timing belt tension

[Standard]

The belt slack should be 3.5 to 4.0 mm when pushing the center of the timing belt with a force of 1.96N (200g).

[Adjustment]

1. Remove the 4 screws of the main PCB and the 2 PCB supporters to remove the main PCB.

2. Loosen the screw 1 of the tension pulley.

3. Adjust the tension on the timing belt by moving the position of the motor holder left or right.

4. Tighten the screw 1 of the tension pulley to secure the tension pulley.

5. Attach the main PCB with the 4 screws and the 2 PCB supporters.

1

XC2277001 Push-pull gauge (5N)

Screw, Pan (S/P washer)

M4X10DB

Tension pulley

Timing belt

Push-pull gauge

1

3.5 - 4.0 mm

Timing belt tension

1.96N (200g)

Loading...

Loading...