4 - 37

Inspection and

Adjustment

Inspection and

Adjustment

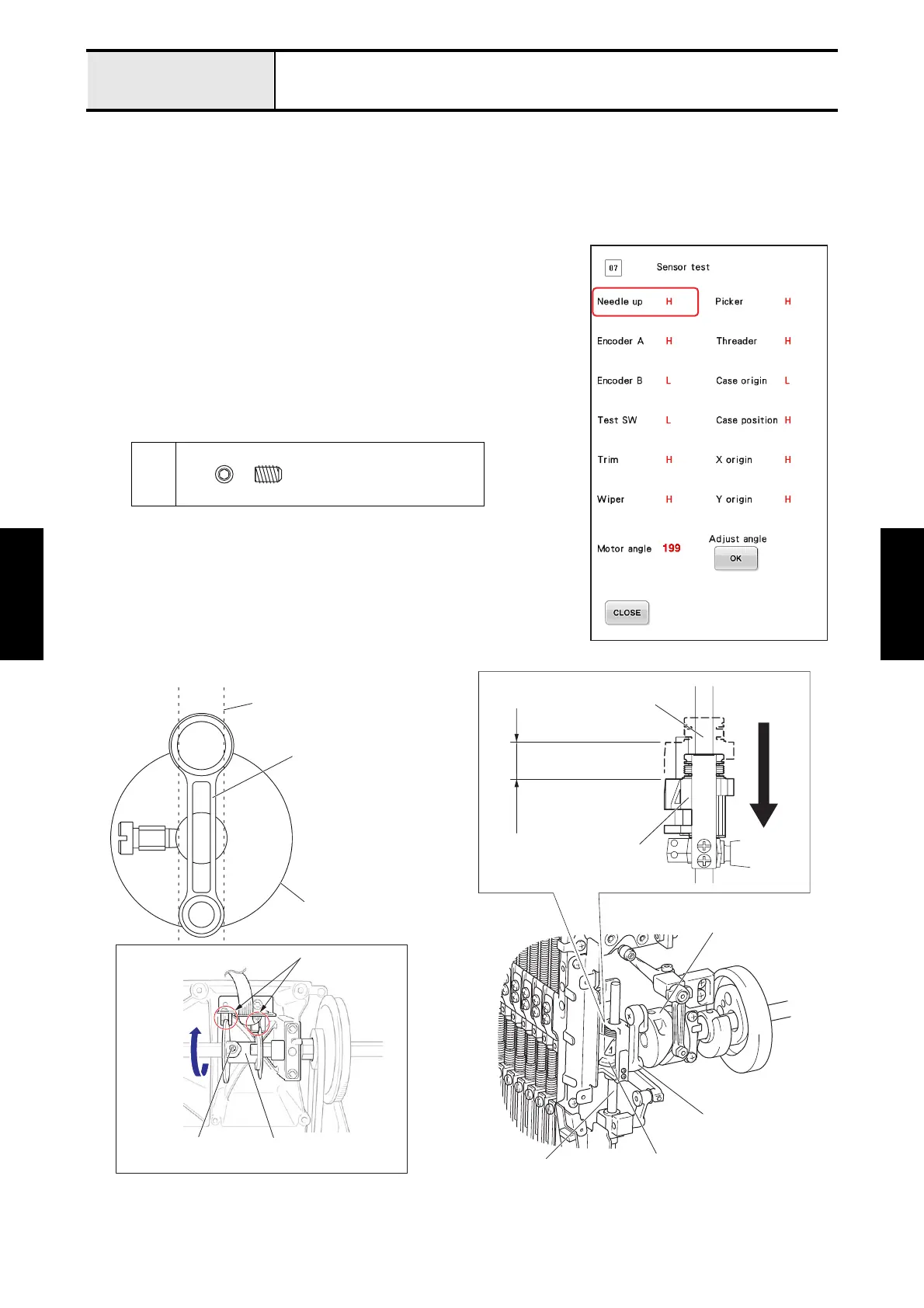

Adjustment Upper shaft encoder phase

[Standard]

When the jump bracket is lowered 19.5 to 20.0 mm from the top dead center position, [Needle up] signal display

should be changed from [H] to [L].

[Adjustment]

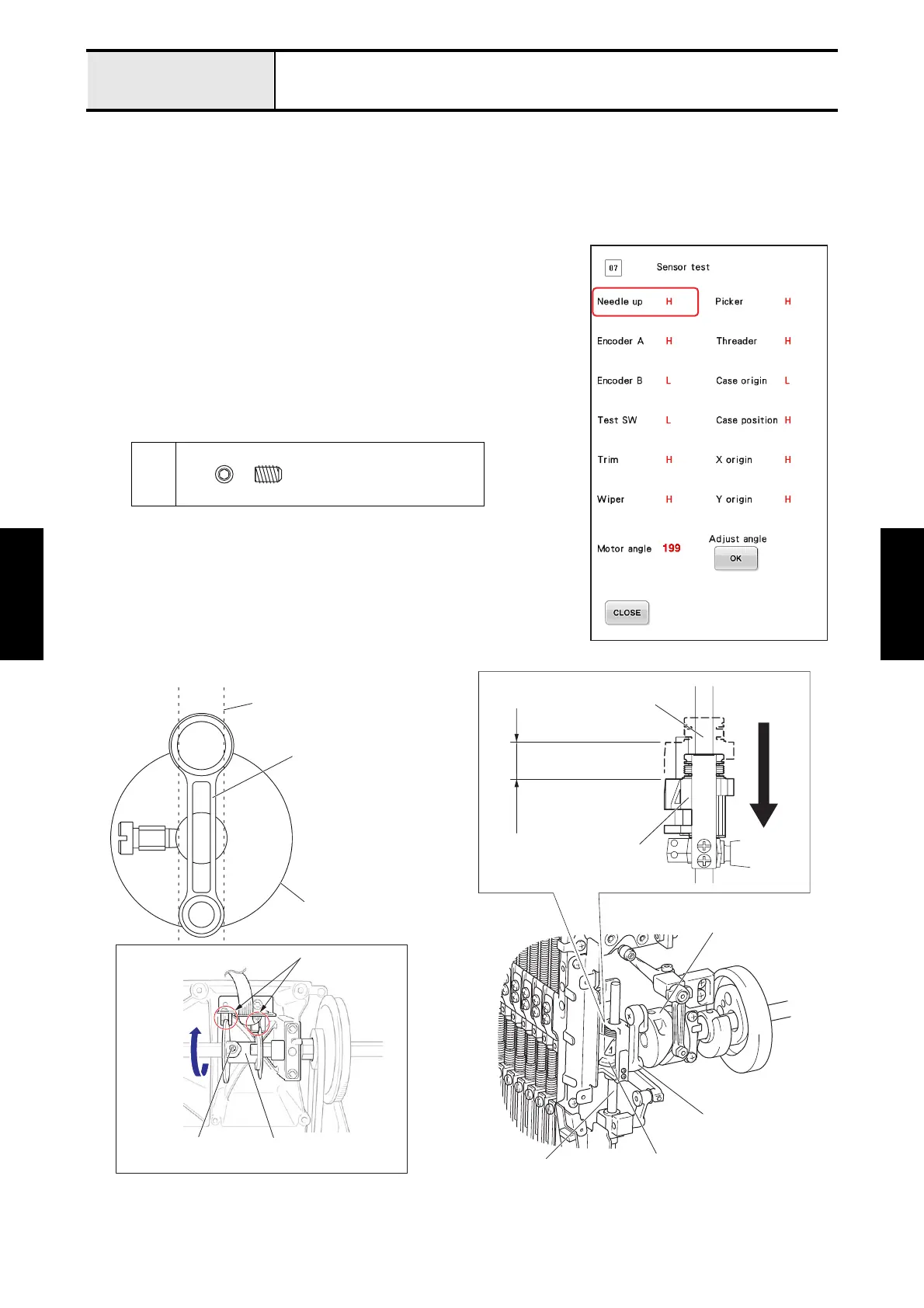

1. Start the test mode and select [#07: Sensor test] under [MAIN BOARD

TEST MODE].

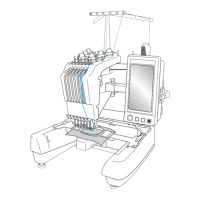

2. Turn the pulley counterclockwise by hand in view from the rear side of

the machine until the jump bracket is lowered 19.5 to 20.0 mm from

the top dead center position (= the crank rod is in a vertical position).

3. Loosen the screw 1 of the encoder base.

4. Turn the encoder base clockwise (direction “A”) in view from the rear

side of the machine until [Needle up] signal display changes from [H]

to [L], and then tighten the screw 1 of the encoder base. (Fig.1)

1

Set Screw, Socket (CP)

M4X6

A

Top dead senter position

Base needle bar

Crank rod

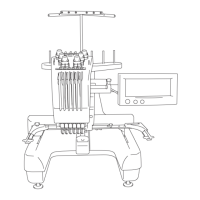

19.5 - 20.0 mm

Thread take-up cam

Not contact

Encoder base

Fig.1

1

Jump bracket

Jump bracket

Base needle bar

Base needle bar

Thread take-up cam

Crank rod

with hex wrench 2 mm

Loading...

Loading...